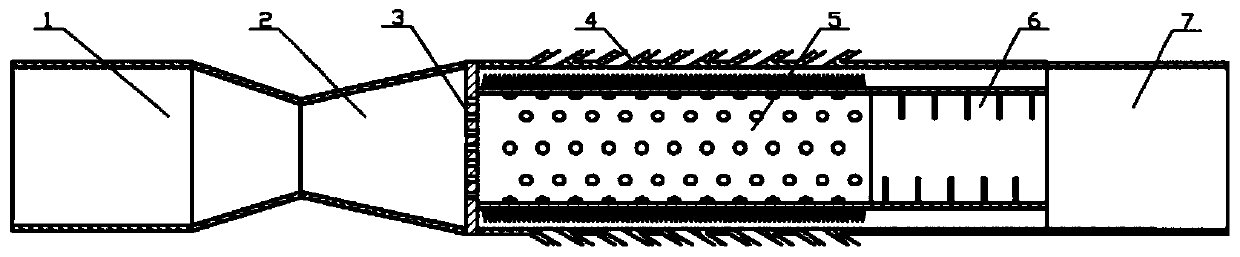

Device and method for cooperatively adjusting steam pressure and temperature

A steam and pressure technology, applied in steam traps, lighting and heating equipment, pipes/pipe joints/fittings, etc., can solve the problems of high outlet steam superheat, inaccurate control, slow response to temperature changes, etc., to reduce Effects of vibration and noise, increased steam volume, and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

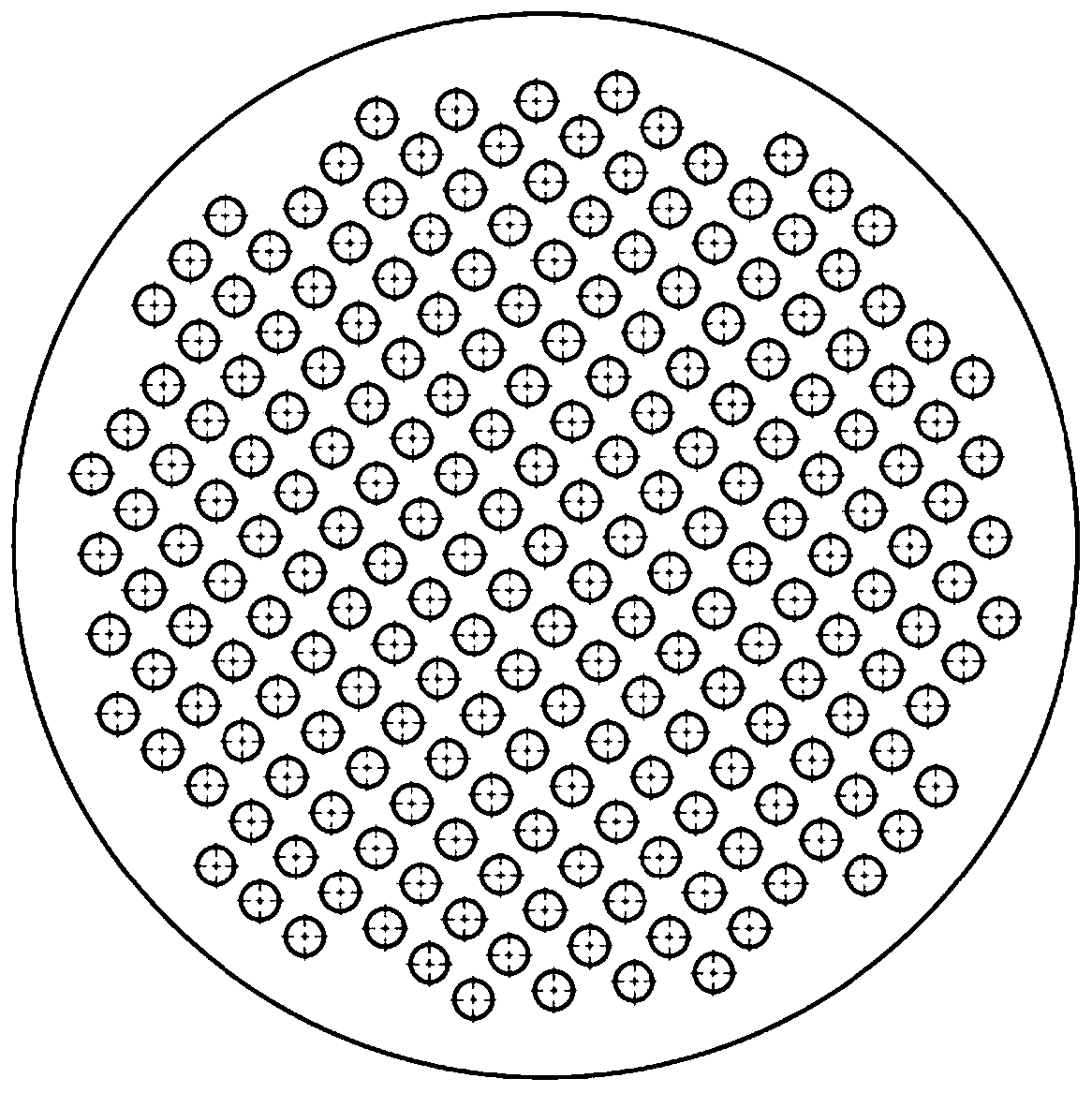

Method used

Image

Examples

Embodiment approach 1

[0036] The steam flows into the steam inlet section 1 with a flow rate of 40t / h, a pressure of 4.0Mpa, and a temperature of 400°C. The orifice is determined according to the pressure and temperature at the large diameter of the throttling and decompression section 2, combined with the user's needs. The level of the board. If the pressure ratio between the front and back of the throttle orifice reaches 0.5, the hole area of the throttle orifice can be calculated according to formula (1):

[0037]

[0038] In the formula, G is the orifice flow rate, t / h; T 0 is the stagnation temperature in front of the orifice plate, K; K" is the coefficient, which can be checked according to the adiabatic index table, here it is taken as 0.667; μ is the flow coefficient; p 0 is the stagnation pressure in front of the orifice, MPa; g is the acceleration of gravity, m / s 2 ; R is the gas constant.

[0039] The hole diameter of the orifice plate is rounded to 20mm. The thickness of the or...

Embodiment approach 2

[0048] According to the steam temperature and steam pressure monitored at the large diameter of the throttling decompression section 2 and the actual use demand, the amount of cooling water is determined to determine the opening and closing of the inclined hole in the cooling water atomizing pipe 4 . According to the relevant theory of gas-liquid two-phase flow, the amount of cooling water is determined based on the calculation principle of material balance and heat balance, and the formula (3) is obtained:

[0049]

[0050] In the formula, W cw is the amount of desuperheating water, kg / h; W os is the output of export steam, kg / h; h is Enthalpy value of imported steam, kJ / kg; h os is the enthalpy value of outlet steam, kJ / kg; h cw is the enthalpy value of cooling water, kJ / kg; h' os is the enthalpy of saturated water, kJ / kg, It is the proportion of the non-evaporated part of the cooling water.

[0051] It is calculated that the initial flow rate of cooling water is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com