Preparation method for lotus leaf tea superfine powder

The technology of lotus leaf tea and superfine powder is applied in the field of preparation of lotus leaf tea superfine powder, and can solve the problems of poor color, aroma, shape, unutilized lotus leaf dietary fiber, single consumption method, etc. , the effect of improving bioavailability and expanding utilization channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

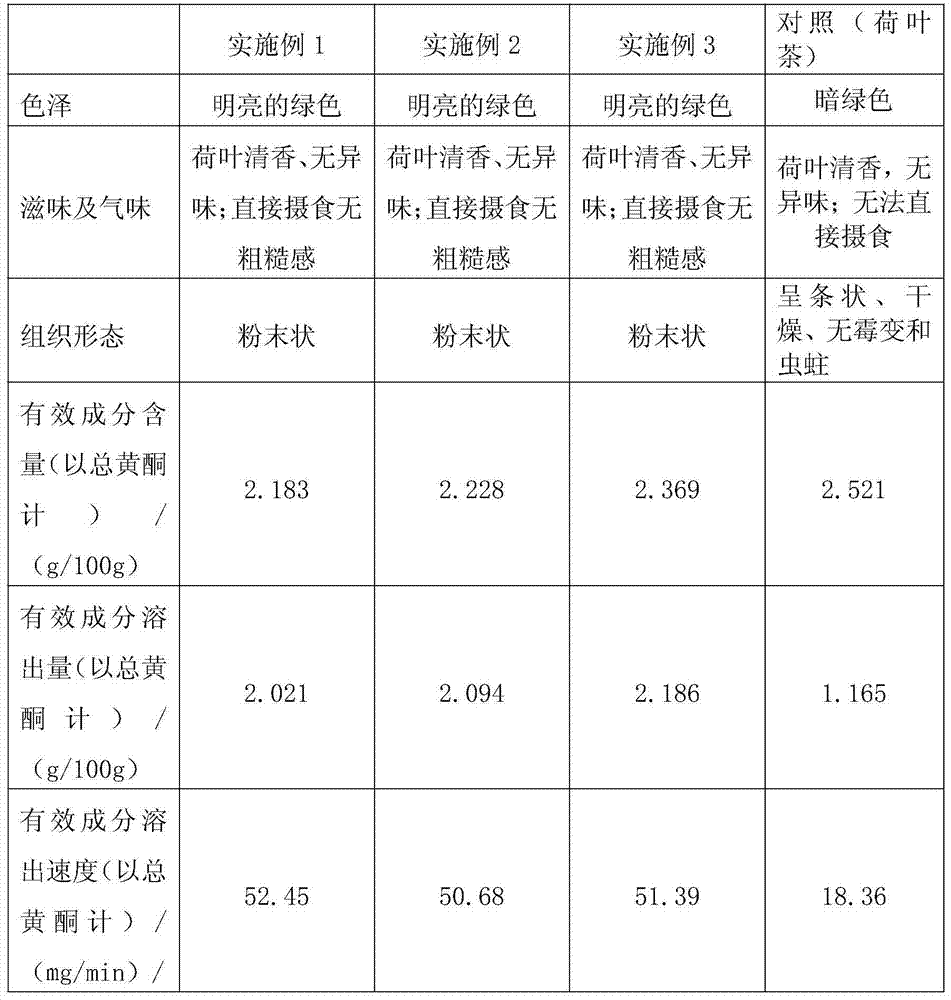

Examples

preparation example Construction

[0019] A preparation method of lotus leaf tea superfine powder, comprising the steps of:

[0020] Step 1. Raw material picking: choose fresh lotus leaves with emerald green color, no defects, and no pollution. The lotus leaf maturity is 7-9 years old.

[0021] Step 2. Withering: The lotus leaves cut into appropriate sizes are placed on a well-ventilated withering bed for spreading and withering. After withering, the water content of the lotus leaves is 65-75%.

[0022] Step 3. Finishing: adopt steam finishing method and use tunnel steam finishing equipment. The thickness of the lotus leaves is 2-4cm, adjust the speed of the belt to control the greening time of the lotus leaves at 2-4min, and adjust the steam input to control the temperature in the tunnel between 85-95°C. It is better to keep the lotus leaves bright green after finishing. After finishing, let it cool down to room temperature immediately. Studies have proved that the color and flavor of the final product of l...

Embodiment 1

[0029] Embodiment 1, a kind of preparation method of lotus leaf tea superfine powder, comprises the steps:

[0030] Take 100kg of lotus leaves, step 1, raw material picking: choose fresh lotus leaves with emerald green color, no defects, and no pollution. The lotus leaf maturity is 7 years old.

[0031] Step 2. Withering: The lotus leaves cut into appropriate sizes are placed on a well-ventilated withering bed for spreading and withering. The thickness of the lotus leaves on the withering bed is 4 cm, and the withering time is 7 hours. The water content of lotus leaves after withering is 70%.

[0032] Step 3. Finishing: adopt steam finishing method and use tunnel steam finishing equipment. The lotus leaves are stacked with a thickness of 2cm, the speed of the belt is adjusted to control the time for the lotus leaves to be greened at 2 minutes, and the steam input is adjusted to control the temperature in the tunnel at 85°C. It is better to keep the lotus leaves bright green...

Embodiment 2

[0036] Embodiment 2, a kind of preparation method of lotus leaf tea superfine powder, comprises the steps:

[0037] Take 100kg of lotus leaves, step 1, raw material picking: choose fresh lotus leaves with emerald green color, no defects, and no pollution. The lotus leaf maturity is 8 mature.

[0038]Step 2. Withering: The lotus leaves cut into appropriate sizes are placed on a well-ventilated withering bed for spreading and withering. The thickness of the lotus leaves on the withering bed is 2 cm, and the withering time is 4 hours. The water content of the lotus leaf after withering is 68%.

[0039] Step 3. Finishing: adopt steam finishing method and use tunnel steam finishing equipment. The thickness of the lotus leaves is 4cm, the speed of the belt is adjusted to control the time for the lotus leaves to be greened at 3 minutes, and the steam input is adjusted to control the temperature in the tunnel at 90°C. It is better to keep the lotus leaves bright green after finishi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com