Sunscreen spray containing solid lipid microparticles and preparation method of sunscreen spray

A sunscreen spray and solid lipid technology, which is applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve problems such as thickening, low solid sunscreen content, and water-oil separation, so as to reduce penetration, Improve centrifugation and low temperature stability, reduce irritation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

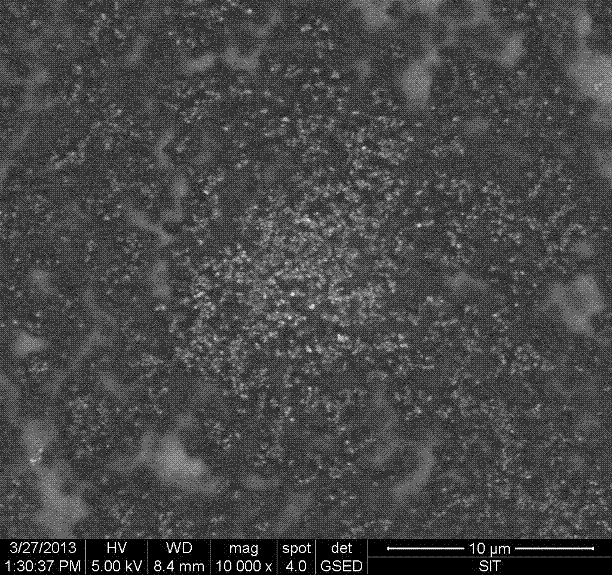

Image

Examples

Embodiment 1

[0060] A kind of sunscreen spray containing solid lipid particles, calculated according to the total amount of 100g, its composition and content are as follows:

[0061] Solid fat 1g (1%)

[0062] Liquid fat 1g (1%)

[0063] Solid emulsifier 3g (3%)

[0064] Solid sunscreen 1g (1%)

[0065] Liquid sunscreen 3g (3%)

[0066] Humectant 0.05g (0.05%)

[0067] Rheology modifier 0.2g (0.2%)

[0068] Preservatives 2g (2%)

[0069] Flavor 0.1g(0.1%)

[0070] The balance is deionized water;

[0071] Wherein the solid lipid is glyceryl monostearate in glycerides;

[0072] The liquid oil is caprylic acid / capric triglyceride in synthetic oil;

[0073] Described solid emulsifier is ceteareth-25;

[0074] Described solid sunscreen is butylmethoxydibenzoylmethane;

[0075] The liquid sunscreen is octyl methoxycinnamate;

[0076] The rheology modifier is Carbomer-U20;

[0077] Described humectant is sodium hyaluronate in macromolecule biochemical class;

[0078] The preservativ...

Embodiment 2

[0093] A kind of sunscreen spray containing solid lipid particles, calculated according to the total amount of 100g, its composition and content are as follows:

[0094] Solid fat 5g (5%)

[0095] Liquid fat 5g (5%)

[0096] Solid emulsifier 7g (7%)

[0097] Solid sunscreen 3g (3%)

[0098] Liquid sunscreen 4g (4%)

[0099] Humectant 5g (5%)

[0100] Rheology modifier 0.25g (0.25%)

[0101] Preservatives 0.2g (0.2%)

[0102] Flavor 0.2g(0.2%)

[0103] The balance is deionized water;

[0104] Wherein the solid lipid is palmitic acid in saturated fatty acids;

[0105] The liquid oil is macadamia nut oil in vegetable oil;

[0106] Described solid emulsifier is steareth-21;

[0107] Described solid sunscreen is butylmethoxydibenzoylmethane;

[0108] The liquid sunscreen is octyl methoxycinnamate;

[0109] Described rheology modifier is xanthan gum;

[0110] Described humectant is glycerin;

[0111] The preservative is diazolidinyl urea;

[0112] Described essence is...

Embodiment 3

[0115] A kind of sunscreen spray containing solid lipid particles, calculated according to the total amount of 100g, its composition and content are as follows:

[0116] Solid fat 5g (5.0%)

[0117] Liquid oil 8g (8.0%)

[0118] Solid emulsifier 7g (7.0%)

[0119] Solid sunscreen 5g(5.0%)

[0120] Liquid sunscreen 8g (8.0%)

[0121] Humectant 10g(10.0%)

[0122] Rheology modifier 0.4g (0.4%)

[0123] Preservatives 0.3g (0.3%)

[0124] Flavor 0.4g(0.4%)

[0125] The balance is deionized water;

[0126] Wherein the solid lipid is cetyl palmitate in wax;

[0127] The liquid oil is isooctyl palmitate in synthetic oil;

[0128] Described solid emulsifier is PEG-20 glyceryl tribehenate;

[0129] The solid sunscreen is 2-hydroxyl-4-methoxybenzophenone-5-sulfonic acid;

[0130] The liquid sunscreen is benzyl salicylate;

[0131] The rheology modifier is polyacrylate-1 cross-linked polymer;

[0132] Described humectant is propylene glycol;

[0133] The preservative is dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com