Preparation method for synthesizing nano SnO2/g-C3N4 composite visible-light-driven photocatalyst by ultrasonic assisted deposition method

An assisted deposition, g-c3n4 technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of nanoparticle agglomeration, long reaction time, high reaction temperature, and achieve high preparation efficiency. , the effect of fast reaction speed and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

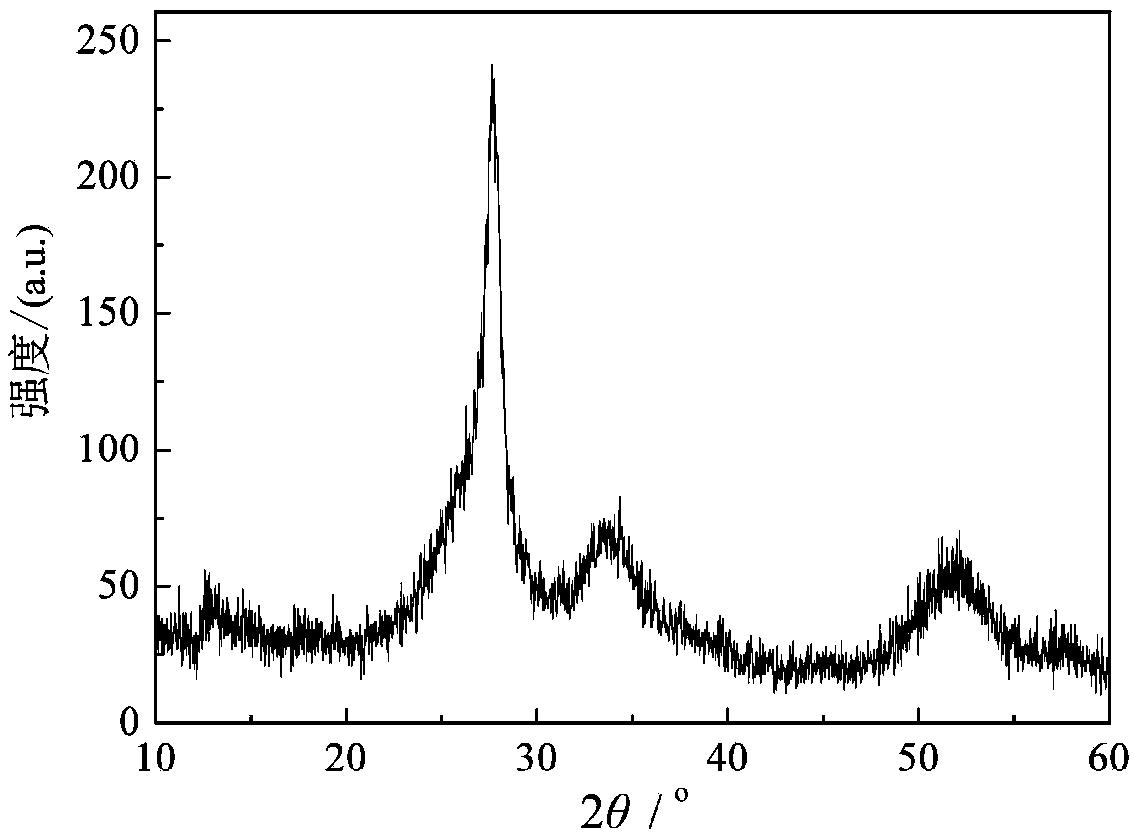

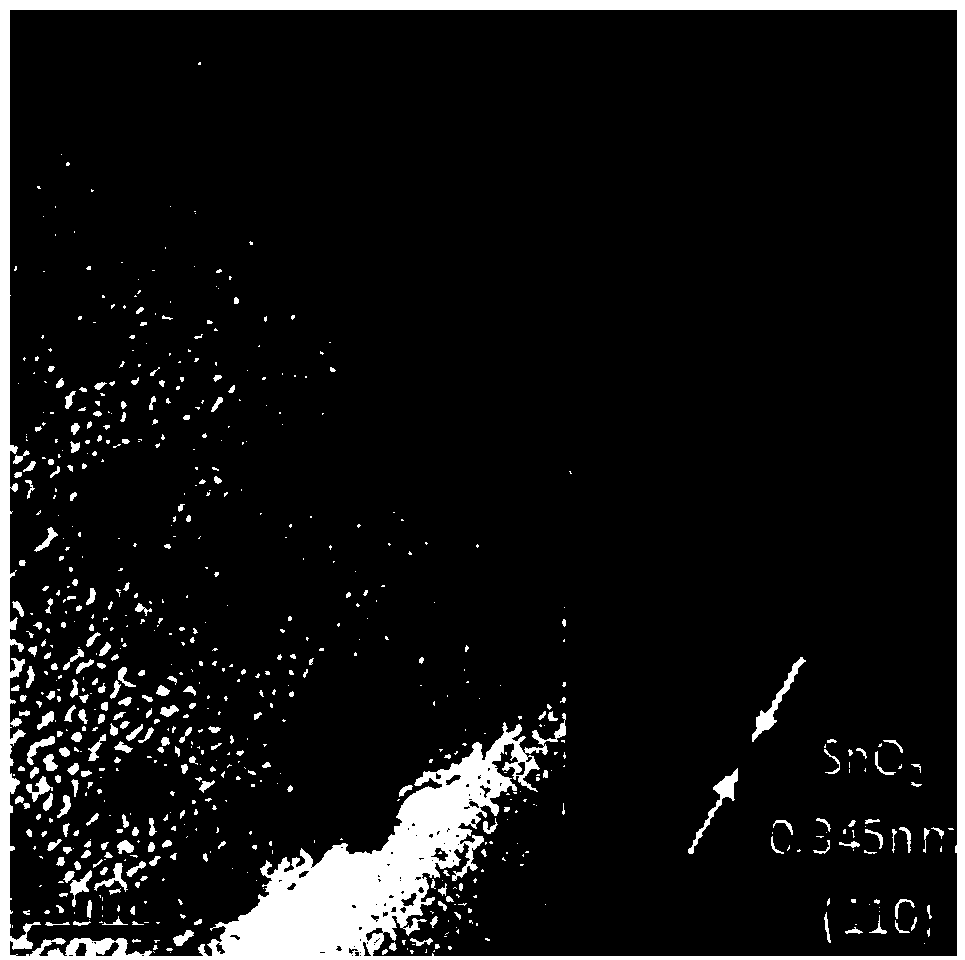

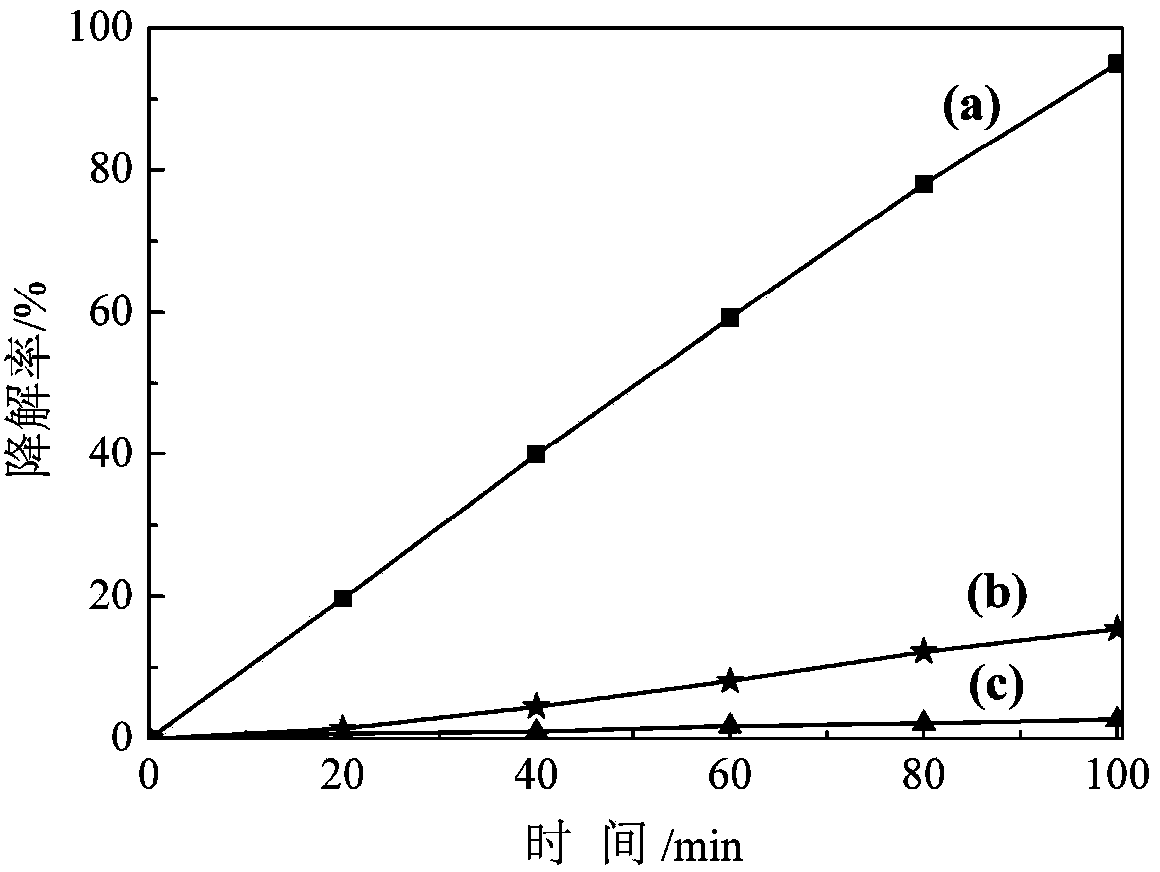

[0024] Example 1

[0025] Take 2.10g SnCl 4 ·5H 2 O was dissolved in 10 mL of methanol, dispersed by ultrasonic for 20 min, and made into SnCl 4 Methanol solution with a concentration of 0.6 mol / L, add dilute ammonia water to adjust the pH to 2.5 under stirring conditions, then slowly add 50 mL of distilled water, continue to stir for 15 min to make the reaction solution evenly mixed, put it in a microwave oven, and put it into a microwave oven. The reaction was heated for 10 min. After the reaction was completed, it was cooled to room temperature and filtered with suction. The filter cake is dried under microwave, and the drying conditions are microwave power 300W and 500W for 3min each, with an interval of 1min, take out and grind to obtain a white powder, which is nano-SnO 2 . Take 15g of melamine in a crucible and put it into a muffle furnace, carry out the polycondensation reaction under semi-closed conditions, set the muffle furnace heating program to heat up to 300°...

Example Embodiment

[0029] Example 2

[0030] Take 4.20g SnCl 4 ·5H 2 O was dissolved in 10 mL of methanol, dispersed by ultrasonic for 20 min, and made into SnCl 4 Methanol solution with a concentration of 1.2 mol / L, add dilute ammonia water to adjust the pH to 2.5 under stirring conditions, then slowly add 50 mL of distilled water, continue stirring for 15 min to make the reaction solution evenly mixed, put it in a microwave oven, and put it into a microwave oven for 300W and 500W microwave power. The reaction was heated for 10 min. After the reaction was completed, it was cooled to room temperature and filtered with suction. The filter cake is dried under microwave, and the drying conditions are microwave power 300W and 500W for 3min each, with an interval of 1min, then take out and grind to obtain a white powder, which is nano-SnO 2 . Take 10g of melamine in a crucible and put it into a muffle furnace, and carry out the polycondensation reaction under semi-closed conditions. Continue to ...

Example Embodiment

[0031] Example 3

[0032] Take 6.20g SnCl 4 ·5H 2 O was dissolved in 30 mL of methanol, dispersed by ultrasonic for 20 min, and made into SnCl 4Methanol solution with a concentration of 0.6 mol / L, add dilute ammonia water to adjust the pH to 2.5 under stirring conditions, then slowly add 100 mL of distilled water, continue stirring for 15 min to make the reaction solution evenly mixed, put it in a microwave oven, and put it into a microwave oven for 300W and 500W microwave power. The reaction was heated for 10 min. After the reaction was completed, it was cooled to room temperature and filtered with suction. The filter cake is dried under microwave, and the drying conditions are microwave power 300W and 500W for 3min each, with an interval of 1min, take out and grind to obtain a white powder, which is nano-SnO 2 . Take 20g of melamine in a crucible and put it into a muffle furnace, carry out the polycondensation reaction under semi-closed conditions, set the muffle furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com