Milling cutter

A technology for milling cutters and cutting blades, which is applied in milling cutters, manufacturing tools, milling machine equipment, etc. It can solve problems such as safety and quality accidents, affect tool accuracy, limit tool speed and cutting efficiency, and achieve accurate positioning and high cutting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

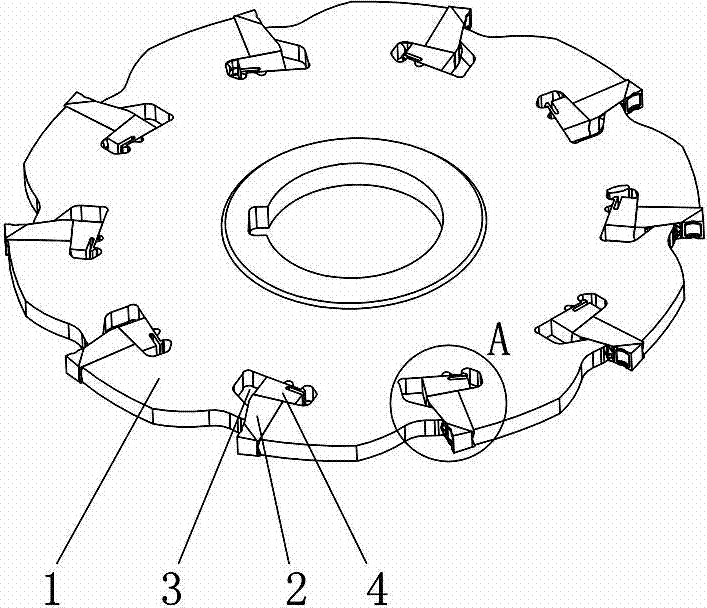

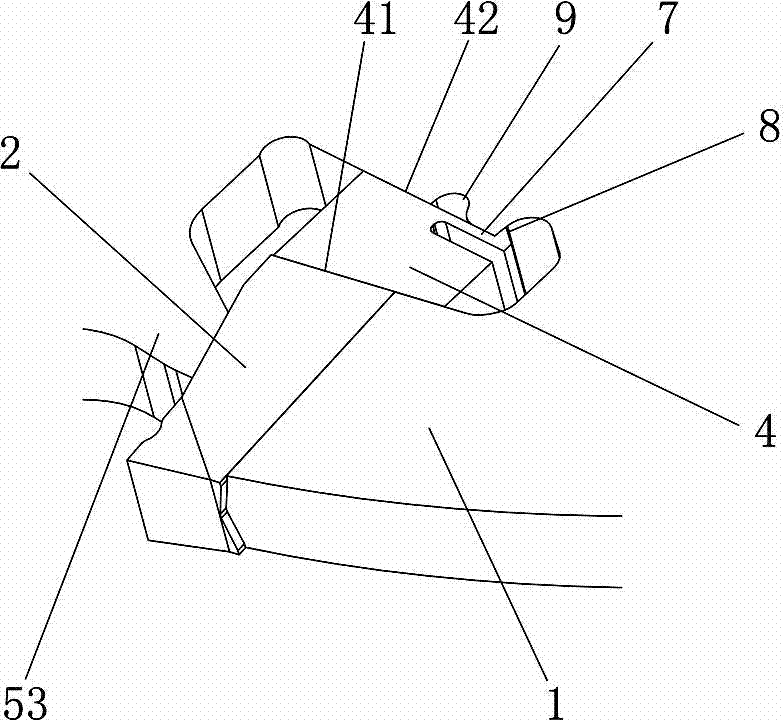

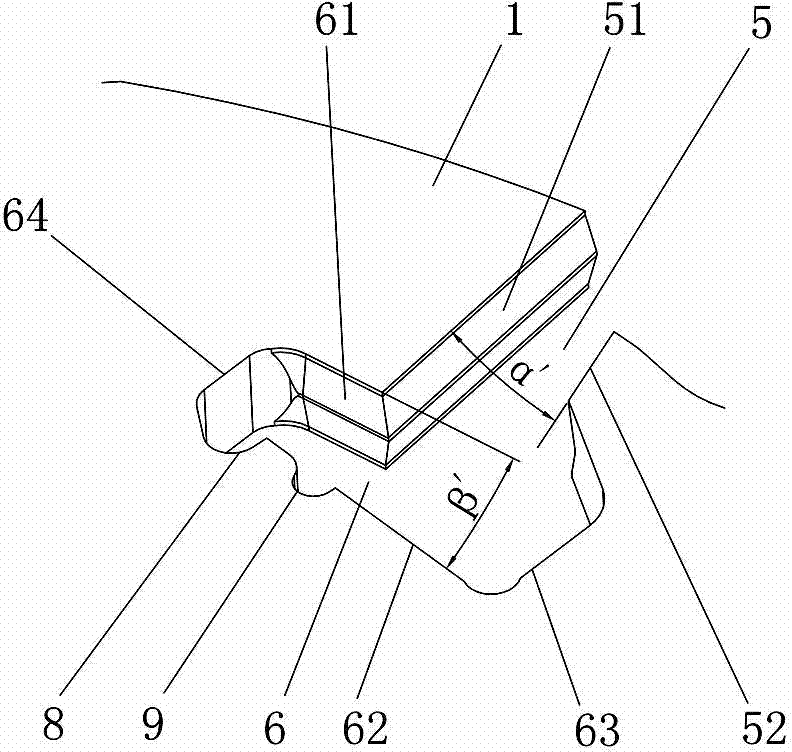

[0031] Figure 1 to Figure 11 An embodiment of the milling tool of the present invention is shown, the milling tool comprises a disc-shaped cutter body 1, a cutting blade 2 and a sipe 3 opened on the outer edge of the disc-shaped cutter body 1, the sipe 3 includes a blade clamping groove 5 and the briquetting mounting groove 6, the bottom surface 21 and the top surface 22 of the cutting blade 2 abut against the first clamping surface 51 and the second clamping surface 52 of the blade clamping groove 5 respectively, and the bottom surface 21 and the top surface 22 face the plate The radially extending planes outside the disc-shaped cutter body 1 intersect to form an included angle α, and the first clamping surface 51 and the second clamping surface 52 intersect to form an included angle α' to the radially extending planes outside the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com