Turnover device for switching body parts

A technology for flipping devices and parts, applied in auxiliary devices, welding/cutting auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of complex and bulky welding equipment, inability to weld, and many parts, and achieve simple structure, less space, The effect of overall equipment simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

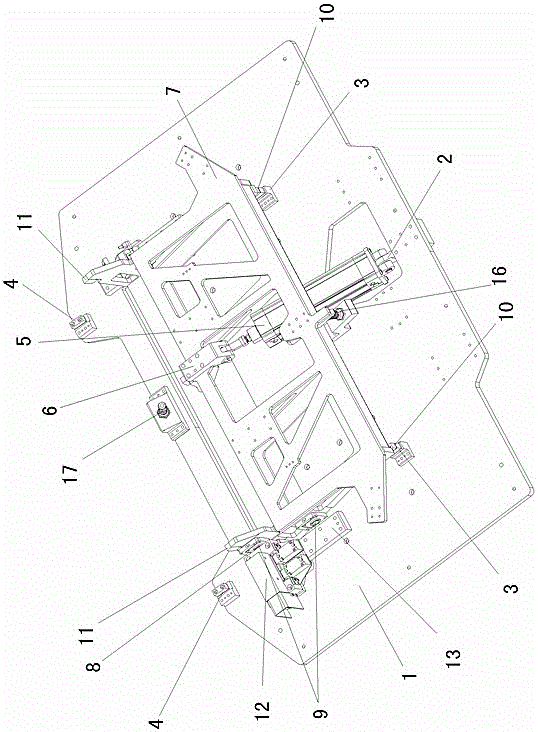

[0009] like figure 1 Shown: 1 is the base plate, on the base plate 1 is connected with the turning plate 7 through the rotating shaft, the bearing seat and the bearing rotation, so that the turning plate 7 is rotatable relative to the base plate 1.

[0010] Between the bottom plate 1 and the turning plate 7, there are a cylinder pushing mechanism for driving the turning plate 7 to rotate, a locking mechanism for two limit positions in the turning direction, and a buffer mechanism for two limit positions in the turning direction.

[0011] The cylinder pushing mechanism includes a cylinder 5 connected to the pneumatic device. The end of the cylinder 5 is connected to the bottom plate 1 through the bracket 2 and the pin shaft. The connecting block 6 is connected in rotation, and when the cylinder 5 moves, it can promote the connecting block 6 and drive the turnover plate 7 to rotate. The rotation axis of the turning plate 7 is located at one side of the connecting block 6 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com