Fold-back ventilating device of collective escaping chamber

A ventilation device and escape cabin technology, which can be used in water rescue, transportation and packaging, ships, etc. It can solve the problems of poor machining accuracy and sealing effect, poor operating reliability of escape cabins, and limited height of ventilation holes, etc., to ensure dynamic balance , to avoid adverse effects, the effect of large output load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

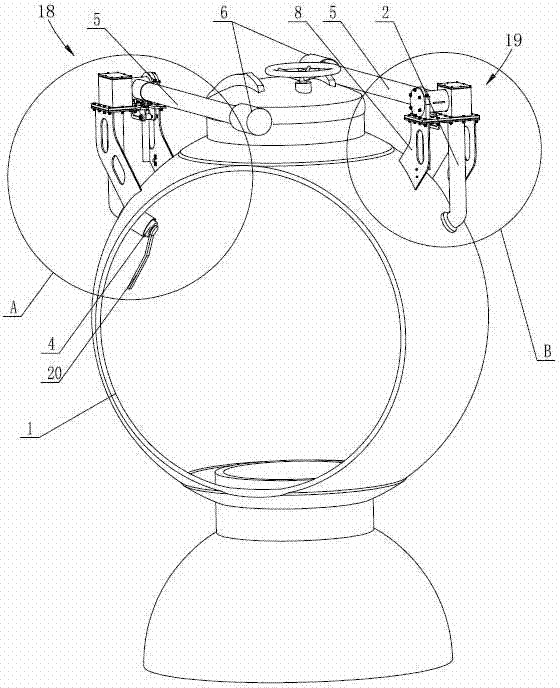

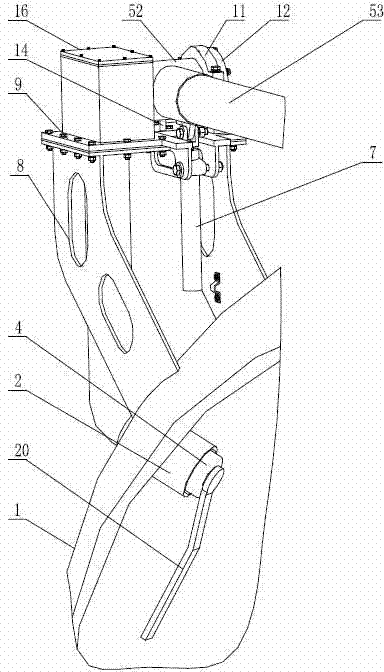

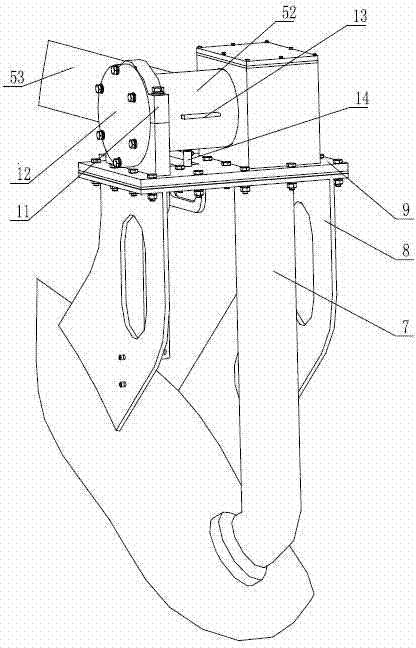

[0029] See figure 1 , the present invention includes an air intake system 18 and an exhaust system 19 connected to the escape cabin body 1, see figure 2 , image 3 , Figure 4 , the air intake system 18 includes a connecting pipe 2, one end of the connecting pipe 2 extends into the escape cabin body 1, and the other end communicates with the conversion cavity 3 outside the escape cabin body 1, the conversion cavity 3 is a closed space, and extends into the escape cabin body The end of the connecting pipe 2 in 1 is equipped with a screw plug 4, and the screw plug 4 can be installed or removed by rotating the handle 20. For the specific connection structure between the connecting pipe 2 and the screw plug 4, see Figure 5 , the connecting pipe 2 is threadedly connected with the screw plug 4, the connecting pipe 2 is provided with a plug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com