Remote control equipment for lifting and transporting building materials in construction sites

A technology for building materials and remote control equipment, which is used in transportation and packaging, conveyor control devices, conveyor objects, etc., can solve problems such as raising production costs, inability to automate, and wasting time, and achieve flexible remote control command and structure. The effect of ingenious and broad promotion and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

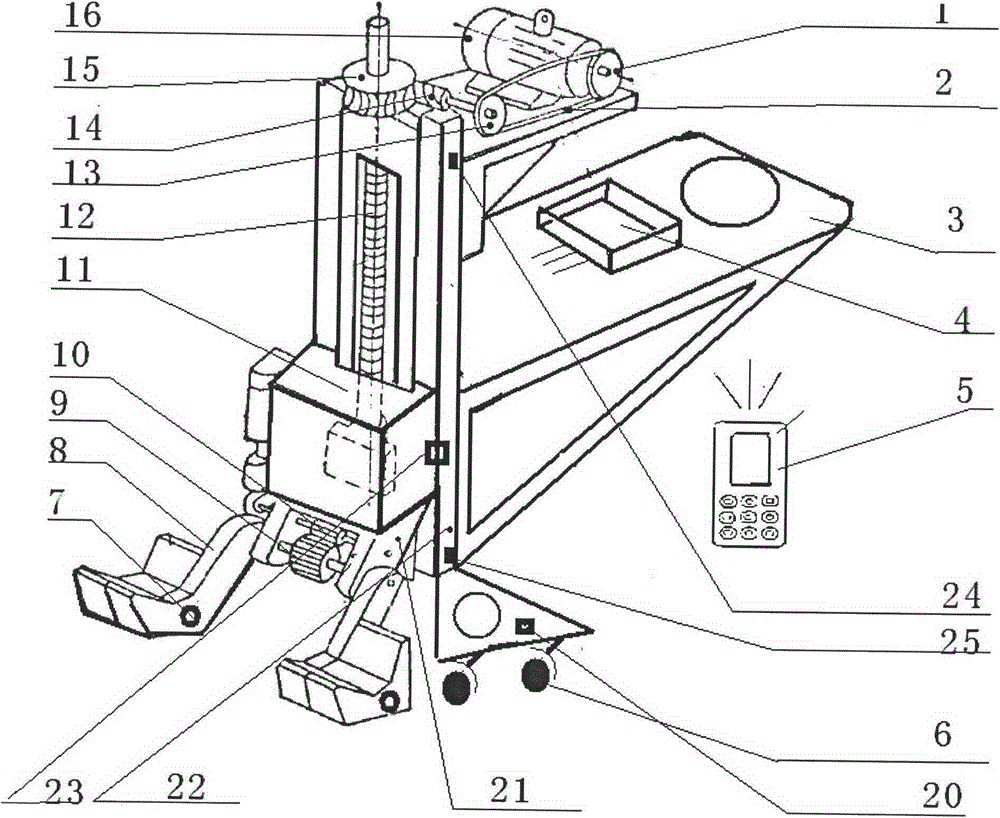

[0024] Such as figure 1 As shown, when building materials need to be raised by lifting, the remote control 5 is operated, the servo steering gear 20 is turned on through the control hub center 4, and the servo steering gear 20 drives the walking wheel 6, and the remote control equipment for snatching and transporting building materials in the entire construction site is You can walk to the destination, turn on the motor 16 through the control center 4 through the remote control 5 again, the motor 16 drives the small pulley 1 to rotate, the small pulley 1 drives the large pulley 13 to run through the belt 2, the large pulley 13 drives the worm 14, and the worm 14 Drive the bronze worm gear 15, the number of wires of the worm 14 is single, and the number of teeth of the bronze worm gear 15 is 60-80 teeth. At this point, slow down considerably. The bronze worm wheel 15 drives the screw mandrel 12 to rotate, and an internal circulation ball screw transmission is adopted between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com