Method for preparing anhydrous magnesium chloride

A technology of anhydrous magnesium chloride and magnesium chloride, which is applied in the direction of magnesium chloride and magnesium halide, can solve the problems of cumbersome operation, high cost, and long time consumption, and achieve the effect of simple process, low equipment requirements, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

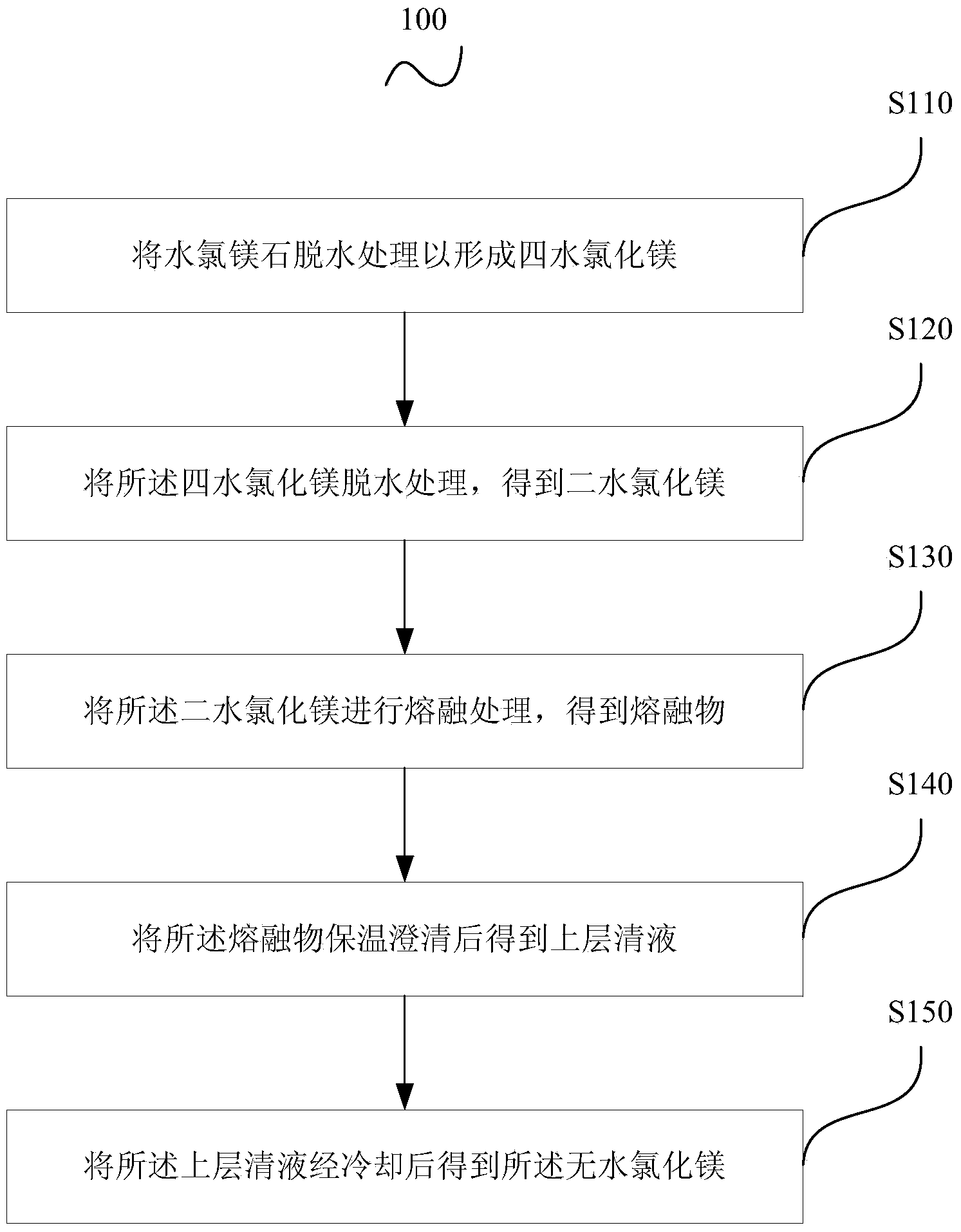

[0024] see figure 1 , figure 1 The step flowchart 100 of the preparation method of the anhydrous magnesium chloride provided for the embodiment of the present invention, from figure 1 Visible in, the preparation method of anhydrous magnesium chloride comprises the steps:

[0025] Step S110: dehydrating bischofolite to form magnesium chloride tetrahydrate;

[0026] Specifically, bischofite is placed in a multi-chamber fluidized bed, and fluidized at a temperature of 75 to 85°C for 20 to 30 minutes to remove the adsorbed water on its surface;

[0027] Then fluidize the bischofite treated in the above steps at a temperature of 105-115° C. for 20-30 minutes to remove crystal water to obtain the magnesium chloride tetrahydrate.

[0028] Preferably, bischofite is Yantian bischofite. It can be understood that the present invention uses bischofite as a raw material, fully utilizes the rich salt lake brine resources in western my country, and has low cost.

[0029] Step S120: dehy...

Embodiment 1

[0040] Put Yantian bischofolite in a multi-chamber fluidized bed, first fluidize it at 75-85°C for 20 minutes to remove its surface adsorption water, then heat it at 105-115°C for 20 minutes to remove two crystal waters, and become Magnesium chloride tetrahydrate;

[0041] The above-mentioned magnesium chloride tetrahydrate was heated at 180°C for 30 minutes to remove two crystal waters to obtain magnesium chloride dihydrate; wherein, the magnesium oxide content in the magnesium chloride dihydrate was 0.2%, and the water content was 27%;

[0042] Put 2 kg of the above-mentioned magnesium chloride dihydrate into a dehydration reactor, and melt for 30 minutes under the conditions of a temperature of 700° C. and a vacuum of 50 mmHg to obtain a melt;

[0043] The above-mentioned molten matter is kept warm and clarified in the dehydration reactor for 40 minutes, and then the supernatant is poured out;

[0044] The clear liquid is naturally cooled to obtain flaky anhydrous magnesiu...

Embodiment 2

[0046] Put Yantian bischofolite into a multi-chamber fluidized bed, first fluidize it at 75-85°C for 25 minutes to remove its surface adsorption water, then fluidize it at 105-115°C for 25 minutes to remove two crystal waters, and become Magnesium chloride tetrahydrate;

[0047] The above-mentioned magnesium chloride tetrahydrate was fluidized at 180° C. for 35 minutes to remove two crystal waters to obtain magnesium chloride dihydrate; wherein, the magnesium oxide content in the magnesium chloride dihydrate was 0.3%, and the water content was 26%;

[0048] Put 2 kg of the above-mentioned magnesium chloride dihydrate into a dehydration reactor, and melt for 35 minutes under the conditions of a temperature of 720° C. and a vacuum of 60 mmHg to obtain a melt;

[0049] The above-mentioned molten matter is kept warm and clarified in the dehydration reactor for 45 minutes, and then the supernatant is poured out;

[0050] The clear liquid is naturally cooled to obtain flaky anhydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com