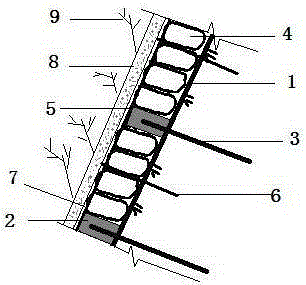

Frame beam ecological slope protection structure and construction method

A technology of ecological slope protection and frame beams, applied in infrastructure engineering, botanical equipment and methods, excavation, etc., can solve the problems of high price of ecological bags, unfavorable plant root growth and penetration, etc., and achieve price reduction and resistance to soil Erosion ability, effect that contributes to soil retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The base layer is a mixture of loam, soil binder, straw decomposing agent and urea. Among them, the soil binder accounts for 0.01% (volume ratio), and the amount of straw decomposing agent is 200g / m 3 , urea 900g / m 3 .

[0048] The components in each cubic layer are:

[0049] Cement: 20L;

[0050] Clay: 830L;

[0051] River sand: 50L;

[0052] Organic matter: 85L;

[0053] Vegetation concrete greening additive: 15L;

[0054] The cement is 325# ordinary Portland cement;

[0055] River sand is clean river sand with a particle size range of 1-2mm;

[0056] Organic matter is a mixture of distiller's grains and crushed rice straw particles, of which the volume of distiller's grains accounts for 60%, and the particle size is less than 20mm;

[0057] The vegetation concrete greening additive uses the product provided by the patent number ZL201110380711;

[0058] The plant seeds are a mixture of grass seeds and shrub seeds, among which, 30g each of bermudagrass and ry...

Embodiment 2

[0066] The base layer is a mixture of loam, soil binder, straw decomposing agent and urea. Among them, the soil binder accounts for 0.02% (volume ratio), and the amount of straw decomposing agent is 400g / m 3 , urea 1200g / m 3 .

[0067] The components in each cubic layer are:

[0068] Cement: 60L;

[0069] Clay: 755L;

[0070] River sand: 100L;

[0071] Organic matter: 60L;

[0072] Vegetation concrete greening additive: 25L;

[0073] The cement is 325# ordinary Portland cement;

[0074] River sand is clean river sand with a particle size range of 1-2mm;

[0075] The organic matter is distiller's grains and rice husk, each accounting for 50% (volume ratio), and the particle size is less than 20mm;

[0076] The vegetation concrete greening additive uses the product provided by the patent number ZL201110380711;

[0077] The plant seeds are a mixture of grass seeds and shrub seeds, including 10g of bermudagrass, 50g of ryegrass, 100g of Magnolia multiflora, 70g of Amorph...

Embodiment 3

[0086] The base layer is a mixture of loam, soil binder, straw decomposing agent and urea. Among them, the soil binder accounts for 0.02% (volume ratio), and the amount of straw decomposing agent is 300g / m 3 , urea 1000g / m 3 .

[0087] The components in each cubic layer are:

[0088] Cement: 60L;

[0089] Clay: 720L;

[0090] River sand: 100L;

[0091] Organic matter: 100L;

[0092] Vegetation concrete greening additive: 20L;

[0093] The cement is 325# ordinary Portland cement;

[0094] River sand is clean river sand with a particle size range of 1-2mm;

[0095] The organic matter is distiller's grains, and the particle size is less than 20mm;

[0096] The vegetation concrete greening additive uses the product provided by the patent number ZL201110380711;

[0097] The plant seeds are a mixture of grass seeds and shrub seeds, including 40g of bermudagrass, 20g of ryegrass, 100g of Magnolia multiflora, and 140g of Rhododendron chinensis;

[0098] According to above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com