Two-way ratchet mechanism

A ratchet mechanism and ratchet technology, applied in the field of two-way ratchet mechanism, can solve the problems of inconvenient and complicated production and use, and achieve the effect of simple structure, convenient and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

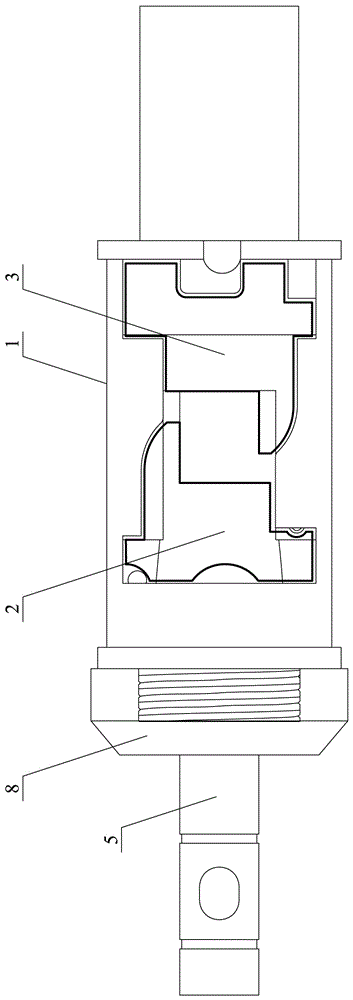

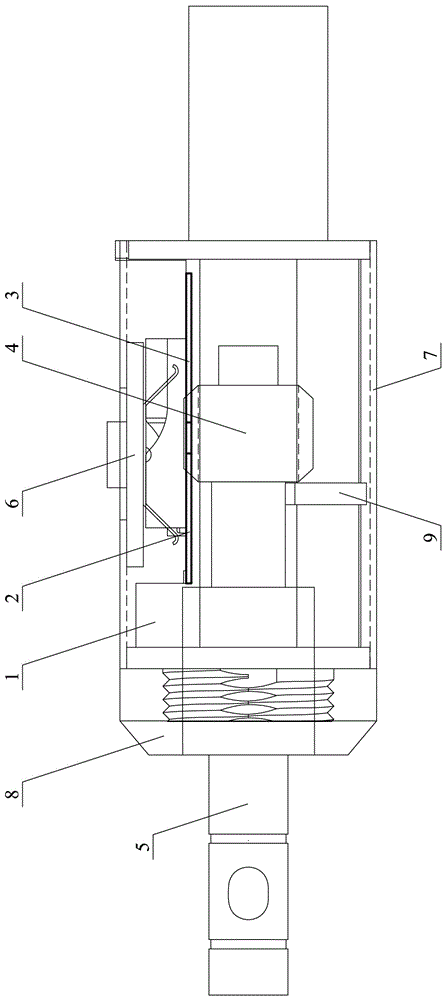

[0018] Embodiment one: see attached figure 1 And attached figure 2 shown. A two-way ratchet 4 mechanism for realizing the same or reverse rotation of the input shaft and the output shaft, including a bushing 1, an upper ratchet 2, a lower ratchet 3, a ratchet shaft 5 with a ratchet 4, and a reversing slider 6 and outer cover 7. Wherein, the shaft sleeve 1 is the input shaft of the two-way ratchet 4 mechanism, and the ratchet shaft 5 is the output shaft of the two-way ratchet 4 mechanism.

[0019] The shaft sleeve 1 is sleeved on the outside of the part of the ratchet shaft 5 that includes the ratchet 4, and has a slot on it. The upper pawl 2 and the lower pawl 3 are oppositely arranged in the slot on the shaft sleeve 1 and located at the center of the ratchet 4. sides. The upper ratchet 2 or the lower ratchet 3 respectively includes the claw tip close to the ratchet 4, the claw tail away from the ratchet 4 and the middle part between the claw tip and the claw tail, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com