Long-stroke water-proof microswitch

A micro switch and long-stroke technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of poor control of pressing force, unstable contact, no operating feel, etc., to increase the pressing feel, prolong the service life, Reset Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

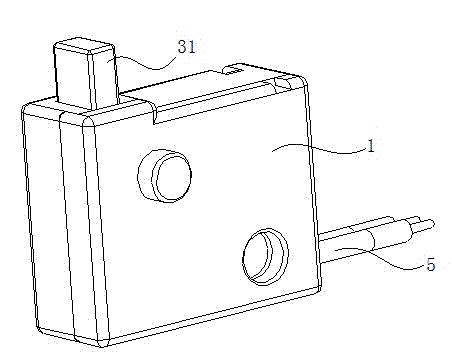

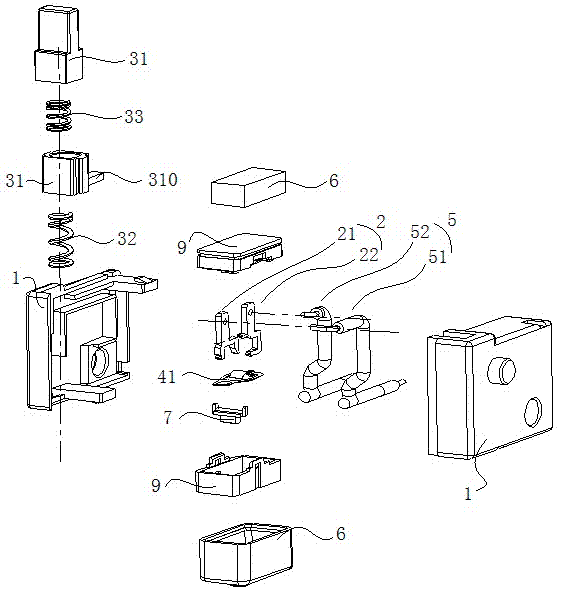

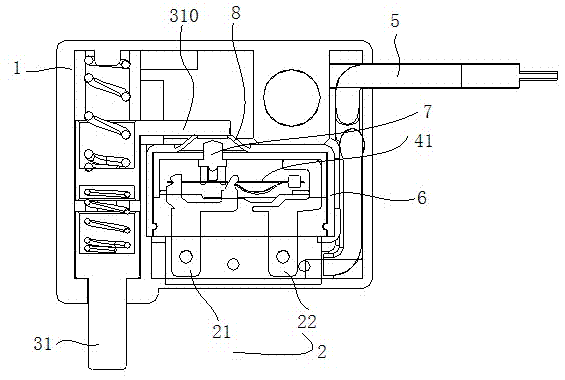

[0029] Such as Figure 1-3 In the illustrated embodiment, the micro switch includes an outer casing 1 , an inner casing 6 , a first terminal group 2 , a button transmission mechanism, a shrapnel transmission mechanism, and a second terminal group 5 .

[0030] The shrapnel transmission mechanism 4 , the second terminal group and the inner casing 6 form a sub-micro switch, and the sub-button 7 is pierced on the casing 6 . The second terminal group consists of a terminal 21 and a terminal 22 arranged side by side. The two terminals are installed in the base 9 . The upper part of the terminal 21 is provided with a bifurcation. The elastic piece 41 is arranged laterally on the terminal 21 , one end and the middle part are respectively sleeved on the two upper forks of the terminal 21 , and the other end is provided with a contact. The first terminal group is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com