Pole group assembling turnover machine of storage battery

A storage battery and turning machine technology, applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery, etc., can solve the problems of high labor intensity, bad quality, affecting production progress and quality, and achieve high production efficiency and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

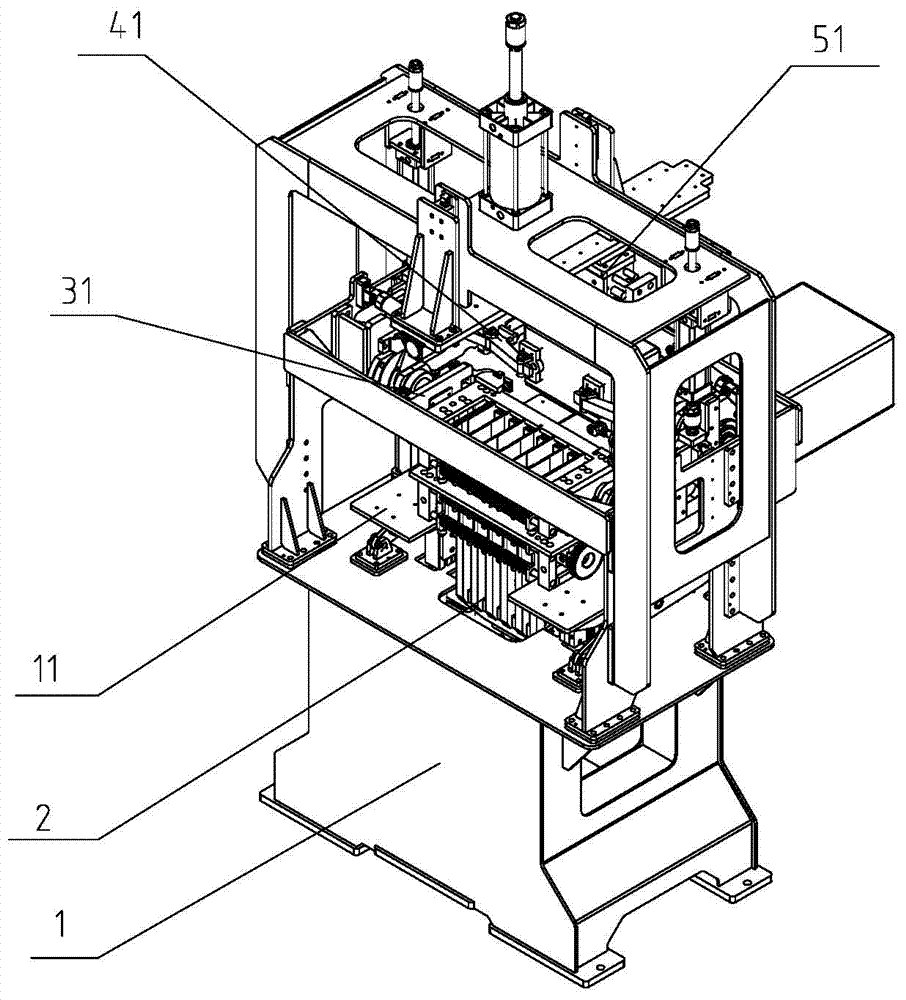

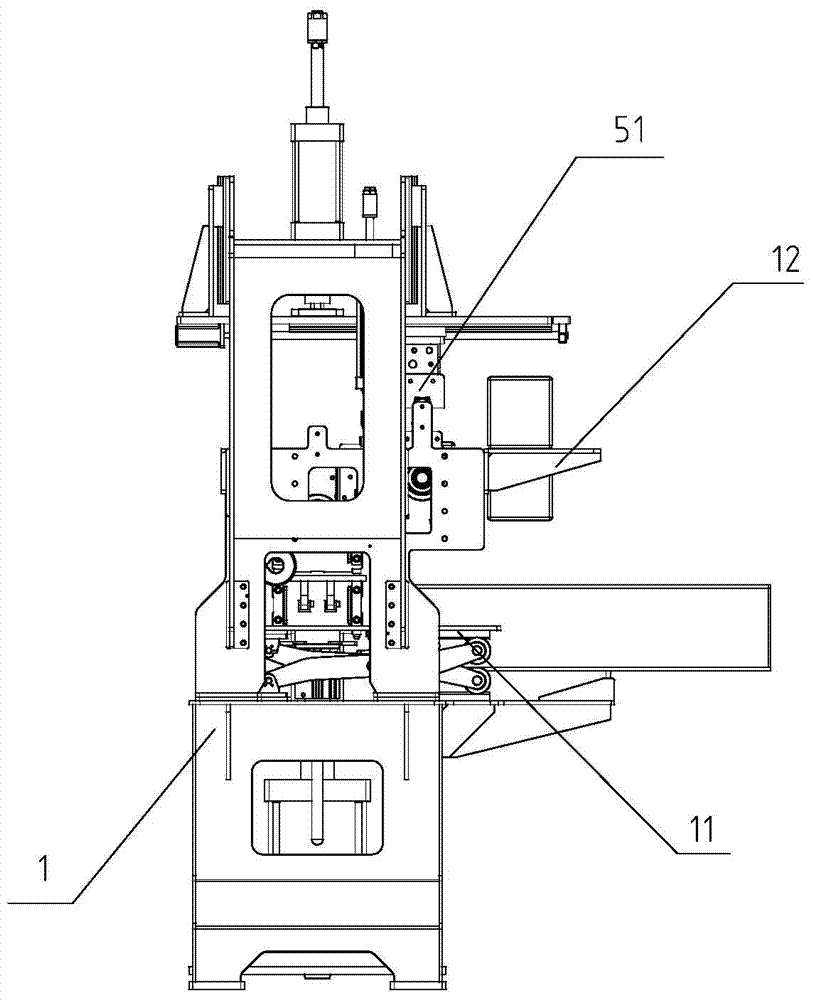

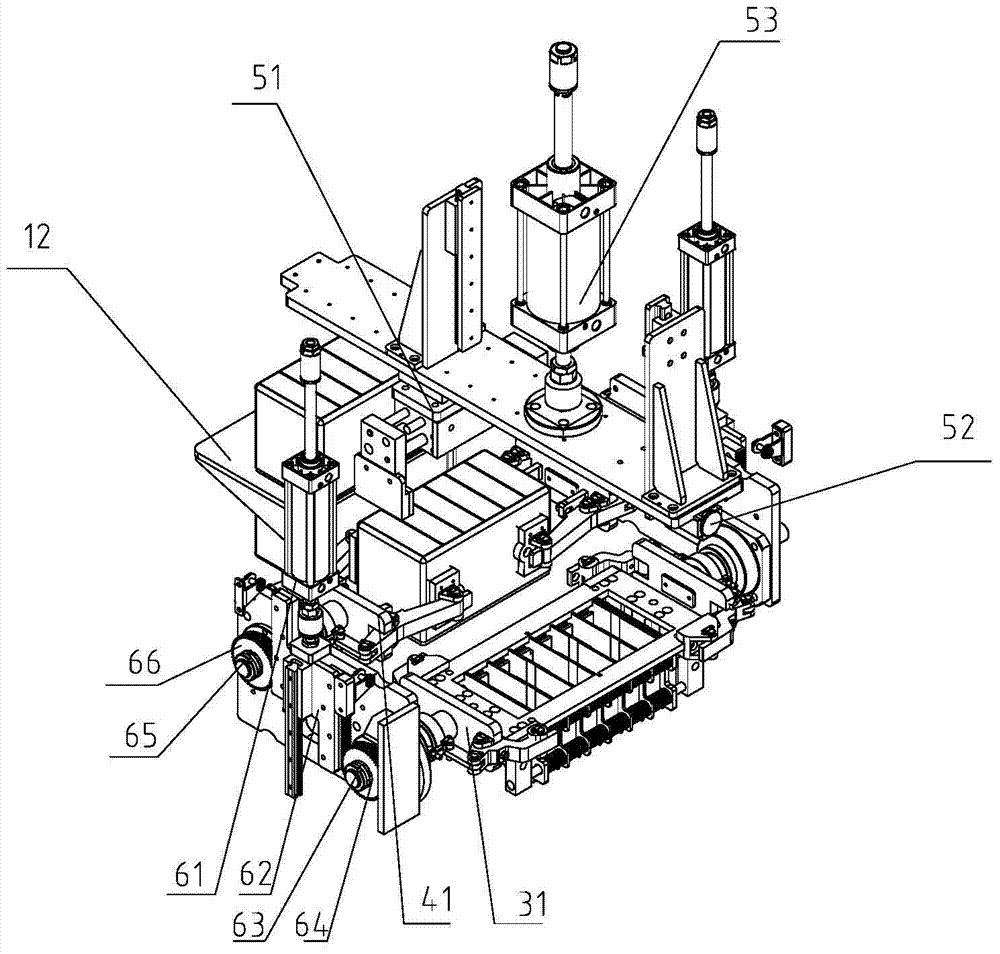

[0025] The invention provides a battery pole group shell-inverting machine, which includes a frame, a shell material platform and a clamp lifting platform are provided on the frame, an ejector device is connected to the clamp lifting platform, and a clamp clamp is arranged above the clamp lifting platform. arm, the top of the clamping arm of the fixture is provided with a shell grabbing arm, and the shell grabbing arm is connected with the first driving member and the driving shell that drive the shell grabbing arm to move between the shell material platform and the clamp lifting platform The second driving part for lifting and lowering the body grabbing arm. The clamping arm of the fixture is provided with a shell clamping arm along the lateral movement side of the shell grabbing arm. Three drivers. Compared with the prior art, the invention realizes automatic production, and can cooperate with other storage battery production equipment, has high efficiency and reduces labor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com