Combined electric probe and processing method for high-speed moving metal flyer test

A metal flyer and processing method technology, which is applied to devices for measuring time intervals, electrical unknown time interval measurement, instruments, etc. problems such as R&D costs and experimental costs, to achieve the effect of reducing research costs, shortening research cycles, and reducing the spray range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing:

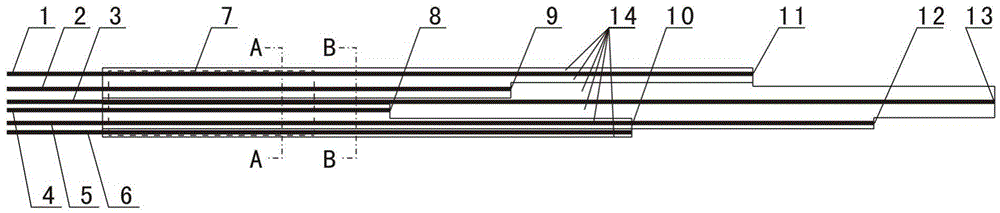

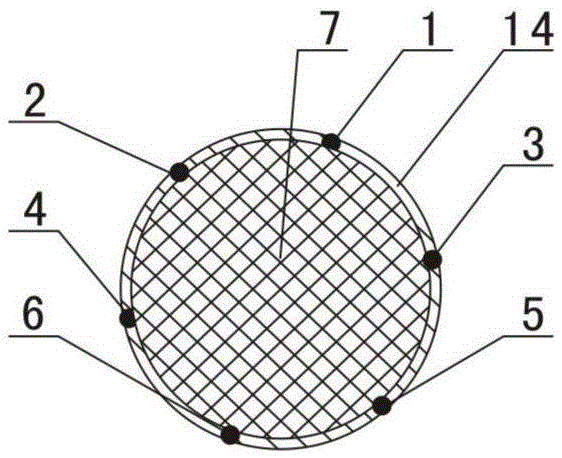

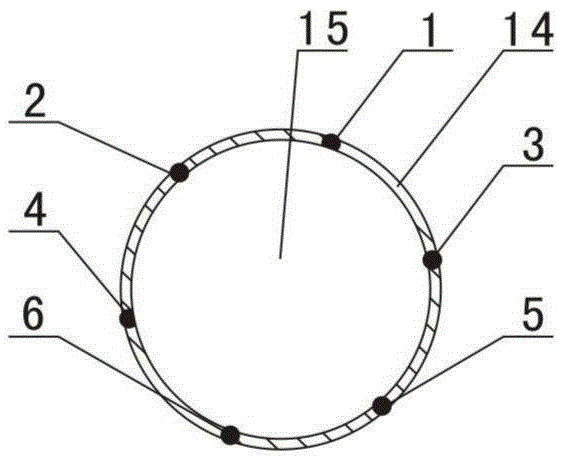

[0047] Such as figure 1 , figure 2 and image 3 Shown, the combined electric probe that is used for the high-speed motion metal flyer test of the present invention comprises film cylinder 14, solid glass cylinder 7 and a plurality of wires, and the quantity of metal wire is determined by the diameter of film cylinder 14 and the distance between the adjacent metal wires. In this example, there are six metal wires, which are the first metal wire 1, the second metal wire 2, the third metal wire 3, the fourth metal wire 4, and the fifth metal wire 5. , the sixth metal wire 6, the adhesive film cylinder 14 is a circular cylinder made of adhesive film, and a plurality of metal wires are evenly distributed on the circumferential wall of the adhesive film cylinder 14 and covered by the adhesive film of the adhesive film cylinder 14 Coating, the metal wire is coaxial with the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com