Recognition method for rotational inertia around z axis and tire cornering stiffness of automobile

A technology of moment of inertia and cornering stiffness, applied in vehicle components, transportation and packaging, driver input parameters, etc., can solve problems such as expensive purchase and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

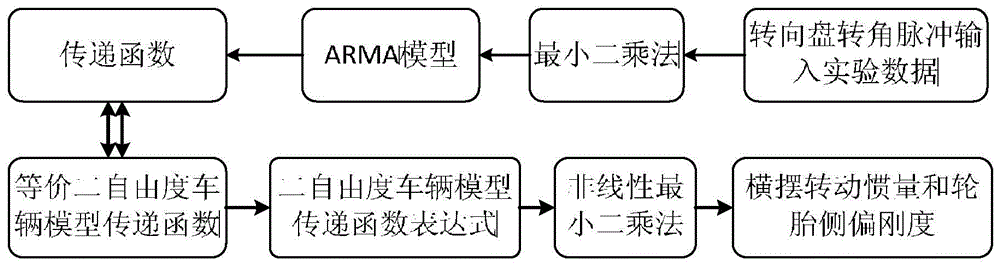

Method used

Image

Examples

Embodiment

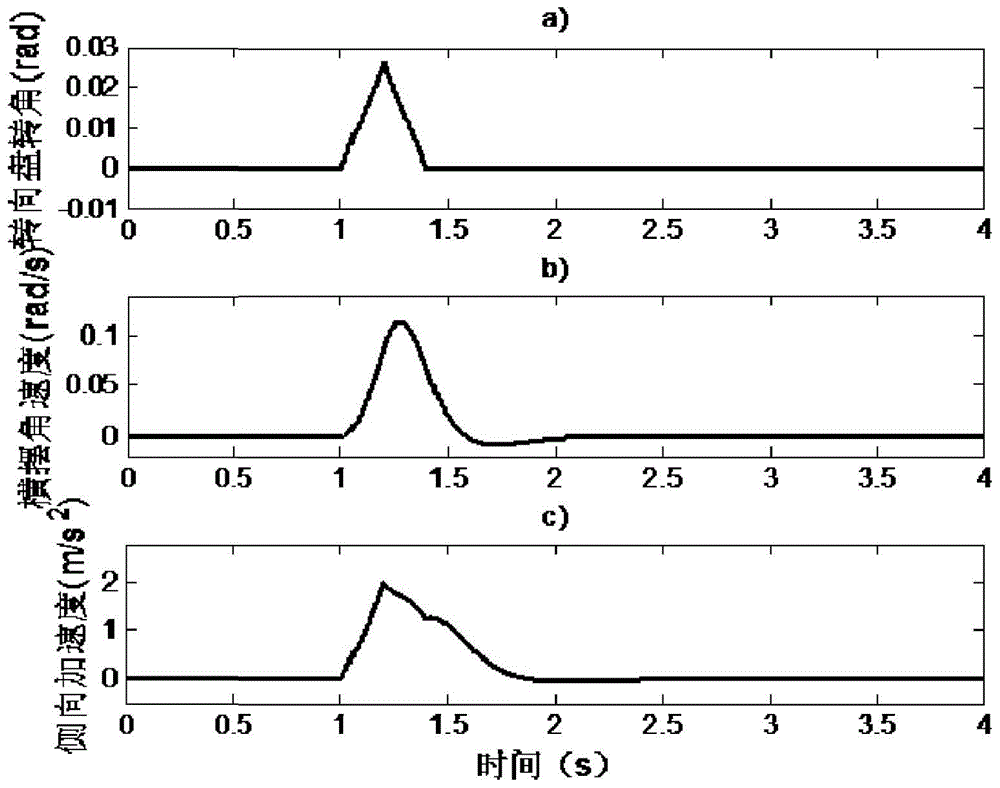

[0070] In this example, the theoretical feasibility of the proposed method is verified by a simulation example. A two-degree-of-freedom vehicle model is established in the simlink environment. The vehicle speed is 100km / h, and the total transmission ratio of the steering system is 16. The vehicle model parameters used are shown in Table 1, and the steering wheel angle pulse input experiment was carried out according to the GB6323 handling stability test standard. Angular pulse experimental data such as image 3 As shown in the figure, a) is the turning angle of the steering wheel; b) is the yaw rate; c) is the lateral acceleration; speed: 100km / h.

[0071]

[0072] Table 1

[0073] The initial value of the optimization variable is estimated according to experience: I Z =2480,K r =59000, K f =55500; boundary constraints are: 2400Z r f z =2510, K r =60010,K f =54800. Figure 4 The frequency response characteristics obtained from the fitting results, the frequency respo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com