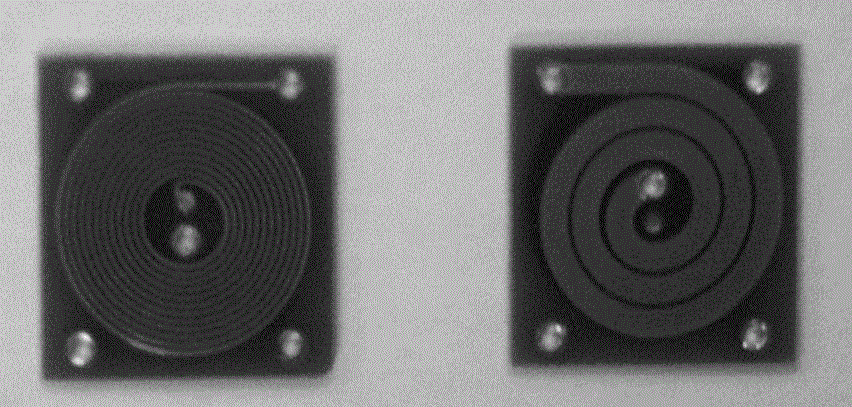

Embedded planar coil array sensor used for blade curved surface crack detection

A planar coil, crack detection technology, applied in the direction of instruments, measuring devices, elasticity testing, etc., can solve the problem of high production cost of flexible array sensors, and achieve the effect of high production cost, low price and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] In the embodiment, an iron-based aero turbine engine blade is selected as the test piece, which is a typical small-curvature surface part. A group of crack defects with different parameters are prefabricated on the blade by electric spark scratching, and its size is (length × width × depth): 10mm×0.1mm×0.3mm, 10mm×0.1mm×0.15mm, 5mm×0.1mm×0.3mm, 5mm×0.1mm×0.15mm, 10mm×0.1mm×0.2mm.

[0032] According to the specific detection steps above, the specific detection results obtained are as follows Figure 9 As shown (due to the large amount of test result data, only a 10mm long crack is taken as an example), it can be seen that there will be a sudden change in the signal amplitude where there is a crack; the imaging effect is as follows Figure 10 shown.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com