Double-trough automatic material returning device

A feeding trough and automatic technology, which is applied in the field of double feeding trough automatic feeding device for cattle, can solve the problems of reducing the fattening speed of beef cattle, increasing the labor cost, reducing the feed intake of cows, etc., so as to save feeding costs and realize Automated and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

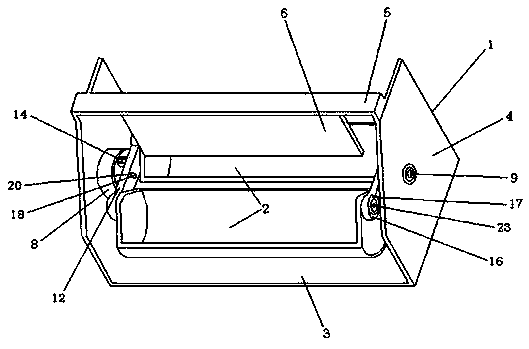

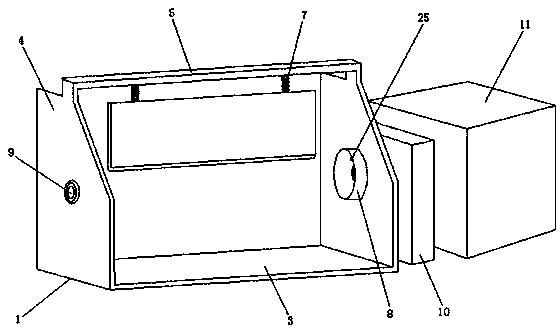

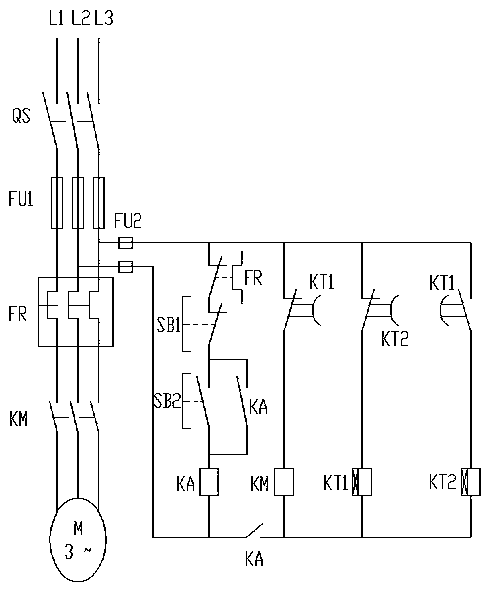

[0020] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a double trough automatic feeding device includes a frame body 1 and a double material trough 2 arranged in the frame body 1. The frame body 1 includes a bottom surface 3, left and right sides 4 and a beam 5 on the top. The frame body 1. The front and back are open surfaces, and the bottom of the beam 5 is equipped with a scraper 6. When the trough 2 runs to the scraper 6, the scraper 6 will scrape out the remaining forage in the upper trough 2, so that the forage falls into the lower trough 2 Inside, the fodder is turned over in the two troughs 2 to ensure the freshness of the forage. The beam 5 and the scraper 6 are connected by a telescopic damping spring 7. A rotating mechanism is arranged between the frame body 1 and the double trough 2. The side 4 in the frame body 1 is provided with a support sleeve 8, and the center of the support sleeve 8 is provided with a shaft hole 9, and the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com