Multistage self-cleaning liquor separation purifier

A liquid separation and purifier technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of clogging water separators, low equipment efficiency, short service cycles, etc., to increase filtration capacity and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

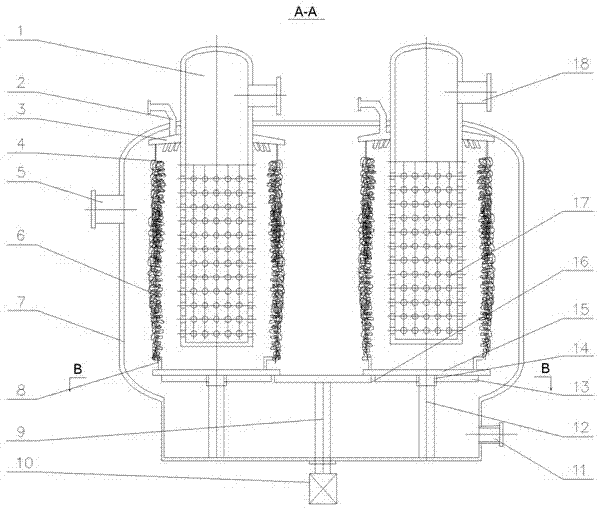

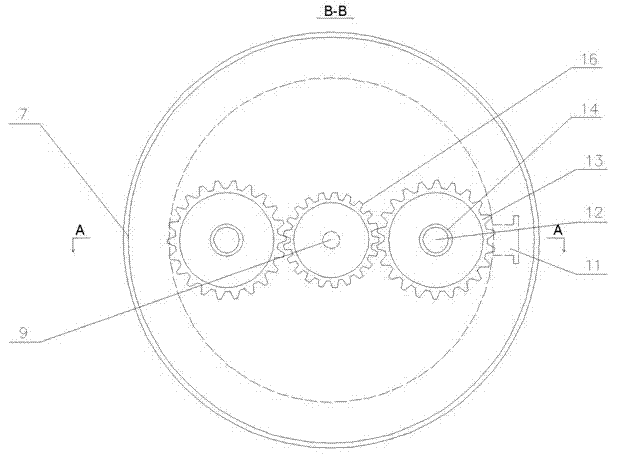

[0016] A kind of self-cleaning liquid separation purifier of the present invention is as figure 1 As shown, the composition of the purifier includes filter cartridge (1), annular cleaning pipe (2), upper fixed disc (3), upper separation medium fixing rod (4), mixture inlet (5), separation medium (6), main body tank (7), lower separation medium fixing rod (8), rotating shaft (9), reciprocating rotating motor (10), sewage channel (11), support column (12), driven gear (13) , support bearing (14), lower rotating disc (15), transmission gear (16), filter hole (17) and clear liquid outlet (18);

[0017] Wherein, the upper part of the tank body of the main body tank (7) is provided with a mixture feed port (5), and the lower part is provided with a sewage channel (11);

[0018] The main body tank (7) is welded with 2 to 4 filter cartridges (1) of the same size, the top of each filter cartridge extends out of the main body tank, and the protruding part is provided with a clear liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com