Grading jaw crusher and toothed plate thereof

A jaw crusher and tooth plate technology, which is applied in the field of mining machinery, can solve the problems that the jaw crusher does not adapt to new process requirements, and achieve the effect of reducing maintenance costs and reducing oil inlet and outlet pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

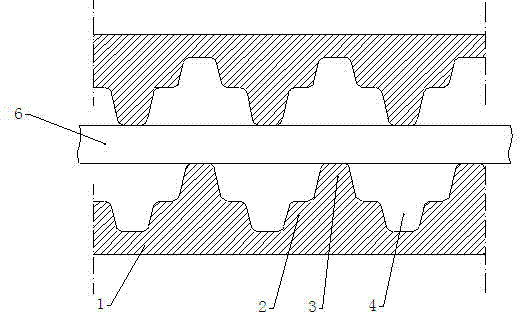

[0019] Example 1: The structure of the tooth plate used in this grading jaw crusher is as follows figure 1 As shown, there are alternate tines 3 and grooves 4 on the tooth plate 1 , so that three steps with different heights are formed on the entire tooth plate 1 . The distance between two adjacent tines 3 is 160 mm, the tooth height is 50 mm, the depth of the groove 4 is 30 mm, and the width is about 50 mm. The sides of the tines 3 and the groove 4 are inclined surfaces. Such as figure 1 As shown, the test plank 6 is placed between the two tooth plates 1. Since the tooth spacing is much larger than that of the original corrugated tooth plates, the test plank 6 can be broken with only a small force. Through experiments, it takes about 800N force to break a 9mm thick, 200mm long, and 16mm wide bar-shaped plank with the common tooth plate of 69 jaw crushers, but it only needs about 300N with the tooth plate of the present invention.

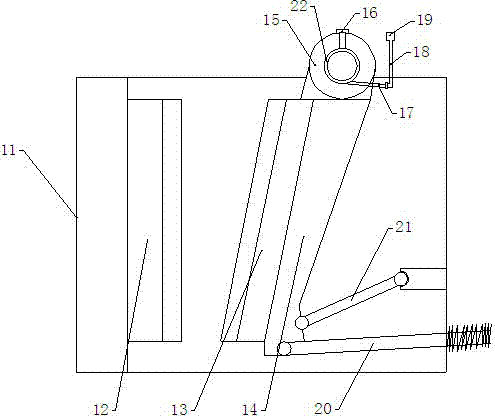

[0020] Both the fixed tooth plate 12 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com