Bellows Forming Mechanism

A forming mechanism and corrugated tube technology, applied in the field of corrugated tube forming mechanism, can solve the problems of irregular forming of the flared part, affecting the performance of the product, and difficulty in plugging and installation, so as to ensure the regularity of the shape, improve the performance and reduce the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

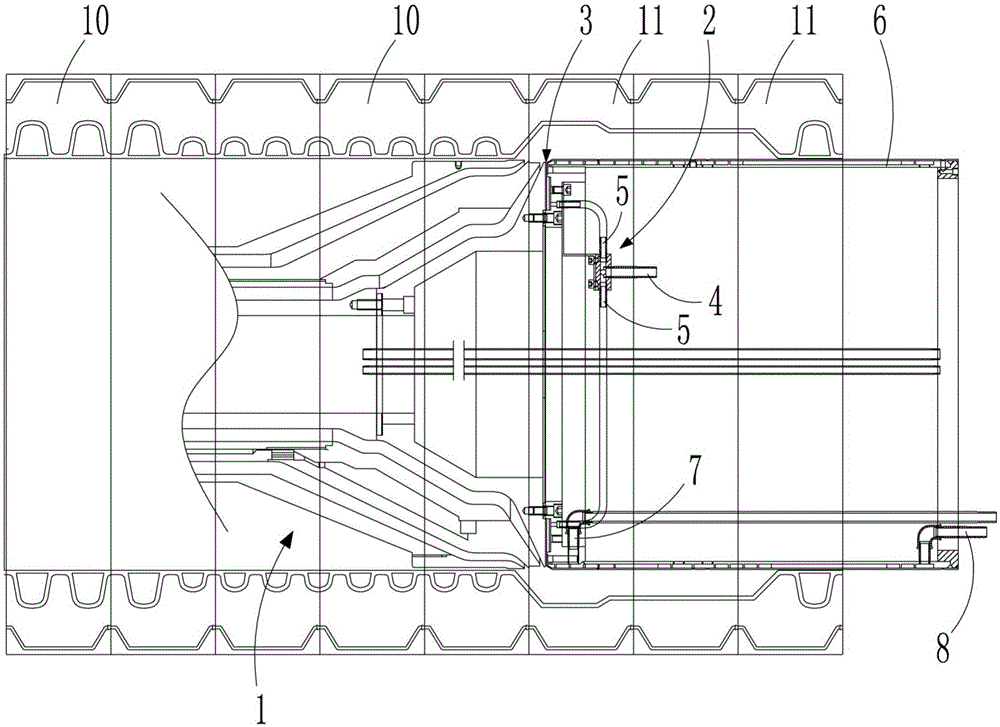

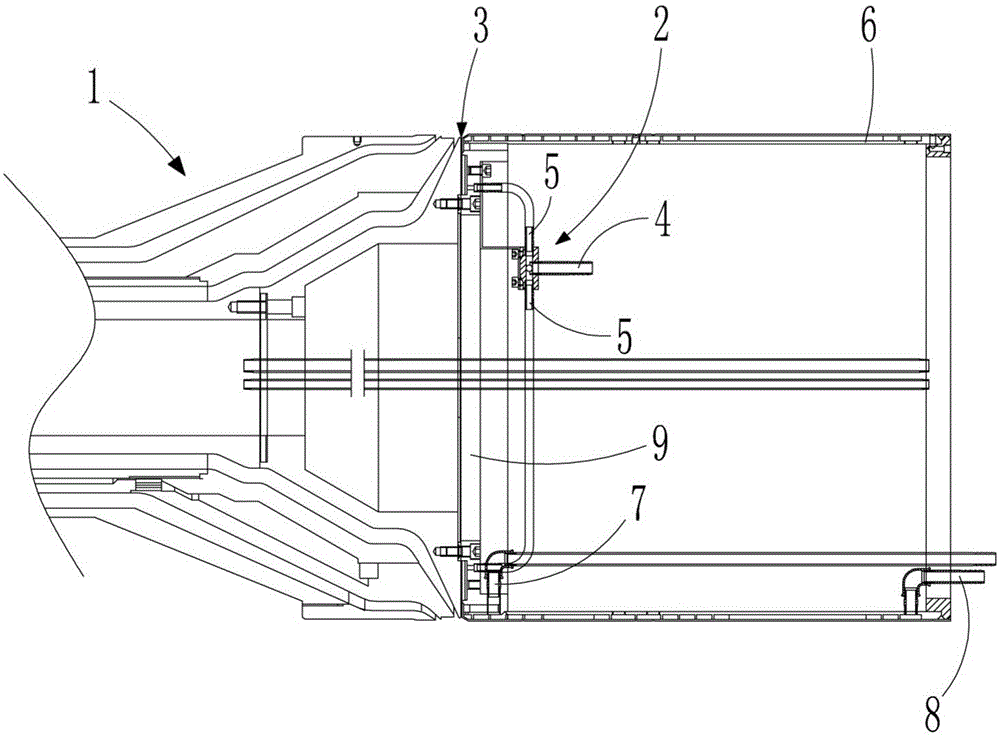

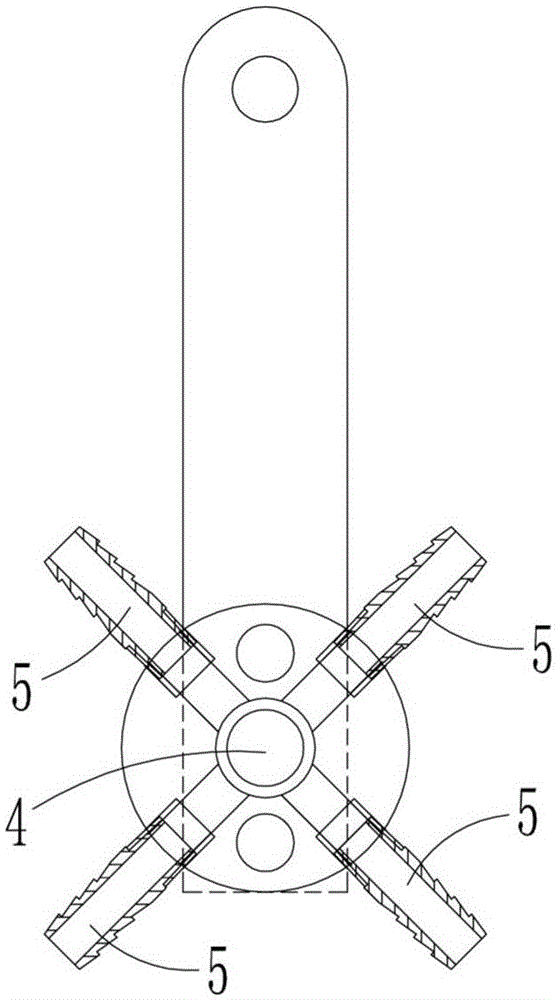

[0018] as attached figure 1 to attach image 3 As shown, a bellows forming mechanism is arranged behind the discharge end of the bellows mold 1, and it includes a modular assembly for forming a bellows on the output of the discharge end, a water cooling assembly, and an air blowing assembly. The modular assembly includes a pumping The vacuum unit, the water cooling assembly is located inside the module assembly, the water cooling assembly is axially fixed behind the discharge end of the bellows mold 1, the bellows is formed between the inner wall of the module assembly and the outer wall of the water cooling assembly, and the air blowing assembly includes a gas splitter 2. The air outlet space is formed between the bellows mold 1 and the water cooling assembly. The air outlet space is surrounded by air outlets 3, that is, gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com