Novel efficient anti-explosion tire

A technology of explosion-proof tires and tires, which is applied to tire parts, transportation and packaging, vehicle parts, etc. It can solve the problems of no improvement in noise, hidden dangers of tire blowouts, and no prevention of sharp objects from being punctured, so as to achieve the effect of preventing sharp objects from being hurt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

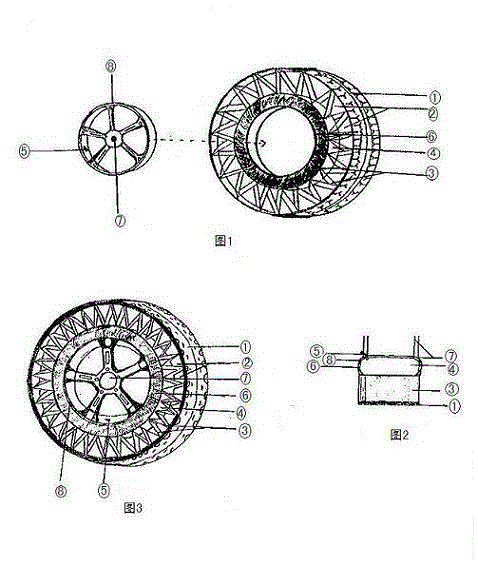

[0019] Such as figure 1 , figure 2 as well as image 3 As shown, the structure of the present invention is firstly introduced, including a tire contact zone 1 that is in contact with the ground, and a number of flexible auxiliary bodies 3 are evenly fixed between the inflatable deformable vacuum carcass 4 and the tire contact zone 1 , and use carbon fiber raw materials and kevlar materials to form elastic cushioning properties to connect and support the tire contact zone 1 where the inflatable deformable vacuum carcass 4 is in contact with the ground, thereby avoiding the inflatable deformable vacuum The carcass 4 is in direct contact with the ground.

[0020] First put the whole tire on the steel ring 7, inflate and expand through the tire inflation nozzle 5, the vacuum carcass section and the thickened tire wall 6 are closely attached to the inner wall 8 of the steel ring, so that the whole tire is fixed on the steel ring 7. During driving, when the tire runs in contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com