Tool for Quickly Installing Door Frame Sealing Strips

A technology of sealing strips and tools, which is applied in the field of tools for quickly installing door frame sealing strips, can solve the problems of slow assembly speed, uneven striking force, and low output, so as to ensure accurate installation, stable and reliable work, and uniform striking force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

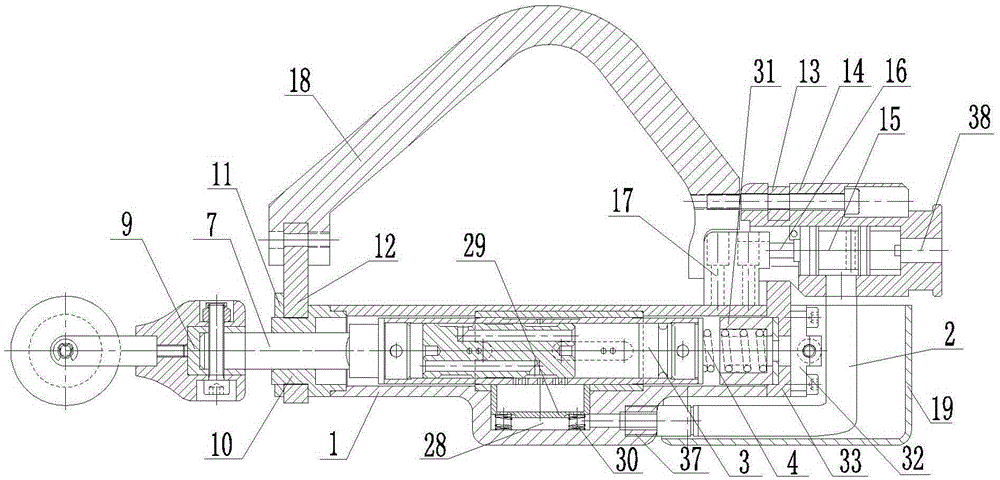

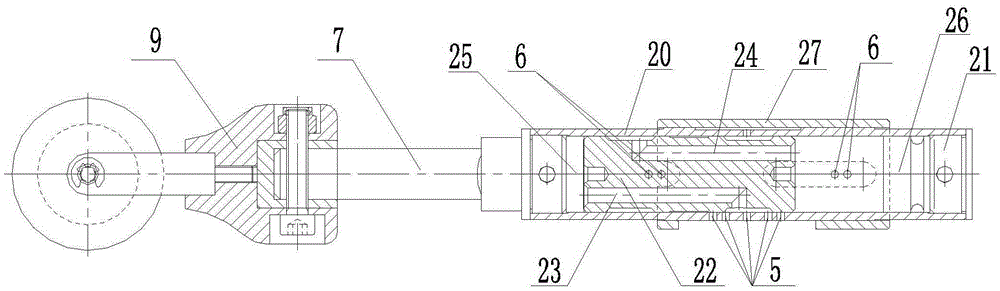

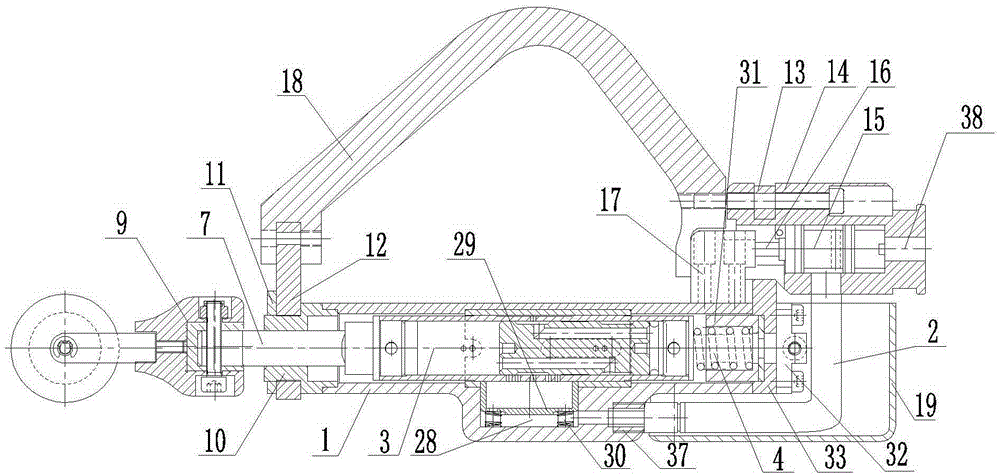

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0030] Such as figure 1 The tool for quickly installing the door frame sealing strip shown in —2 includes a tool housing 1, which is connected with an air intake pipe 2, and a telescopic cylinder 3 is arranged in the tool housing 1, and the air inlet of the telescopic cylinder 3 is connected to the air intake pipe. The air outlet of the air pipe 2 is connected, the output end of the telescopic cylinder 3 is connected with a guide shaft 7, the front end of the guide shaft 7 is fixed with a vibration head 9 corresponding to the shape of the door frame sealing strip, and the rear end of the tool housing 1 is provided with a device Exhaust holes 8; the front end of the tool housing 1 is fixed with a first shock absorber 12, and the rear end is fixed with a second shock absorber 13 and a collision block 17, between the first shock absorber 12 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com