A fully automatic powder adding machine

A fully automatic, powder box technology, applied in the direction of the shape of the heating element, can solve the problems of high noise of the vibrating device, frequent vibration of the powder feeder, and can not satisfy the manufacturer, and achieves fast powder flow rate, good rotation effect, and avoidance of waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

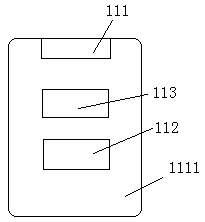

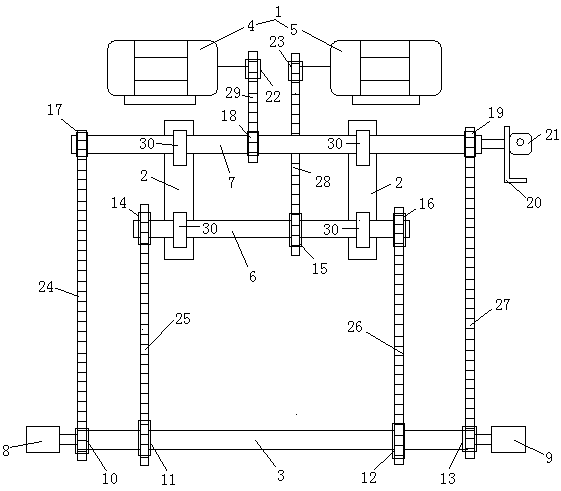

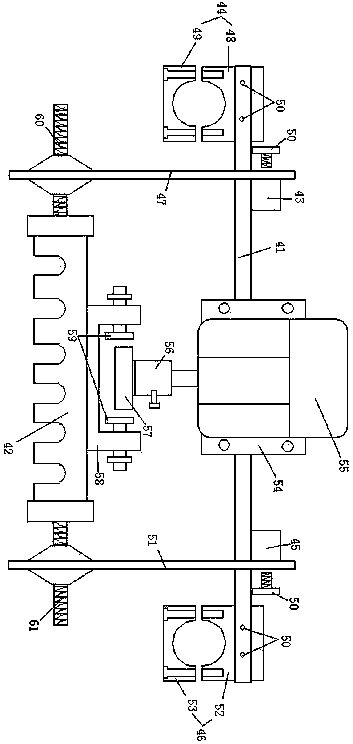

[0014] As shown in the figure, a fully automatic powder adding machine includes a powder adding machine 1111. The powder adding machine 1111 is provided with a transmission device 111, a vibrating device 112 and a powder dropping device 113. The transmission device 111 includes a clutch Motor 1, bearing seat 2 and first rotating shaft 3, described clutch motor 1 includes first clutch motor 4 and second clutch motor 5, described bearing seat 2 is provided with second rotating shaft 6 and third rotating shaft shaft 7, the first rotating shaft 3 is provided with a first flange 8 at one end, and a second flange 9 at the other end, and a first flange 8 and a second flange 9 are provided between the first flange 8 and the second flange 9. The sprocket 10, the second sprocket 11, the third sprocket 12 and the fourth sprocket 13, the second rotating shaft 6 is provided with the fifth sprocket 14, the sixth sprocket 15 and the seventh sprocket 16 , the eighth sprocket 17, the ninth spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com