Flexible mechanical connector applied to ultra-large type ocean floating structure modules

A technology between floating structures and modules, which is applied in the direction of mechanical equipment, floating buildings, fixing devices, etc., can solve the problems of deformation manufacturing accuracy, welding difficulty, drop, etc., and achieve the effect of high reliability and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the drawings.

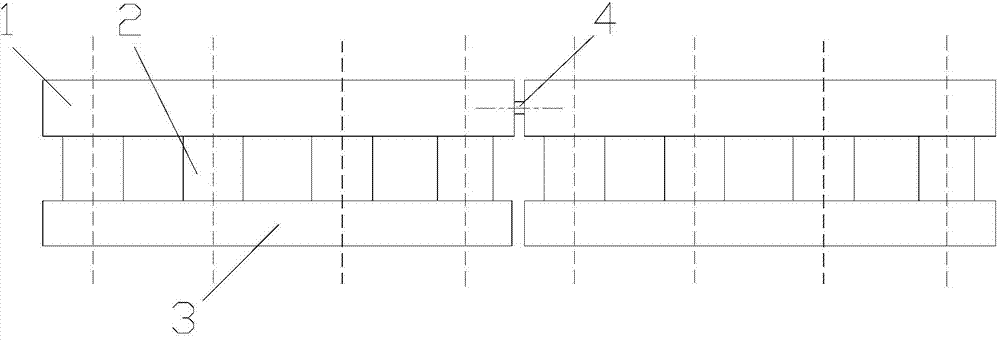

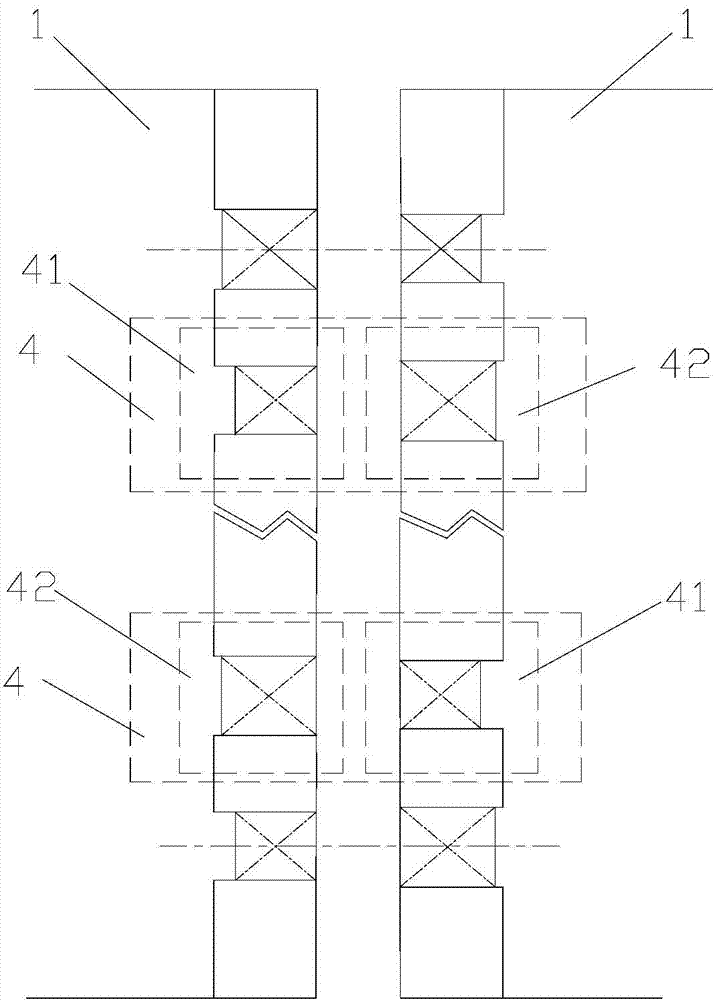

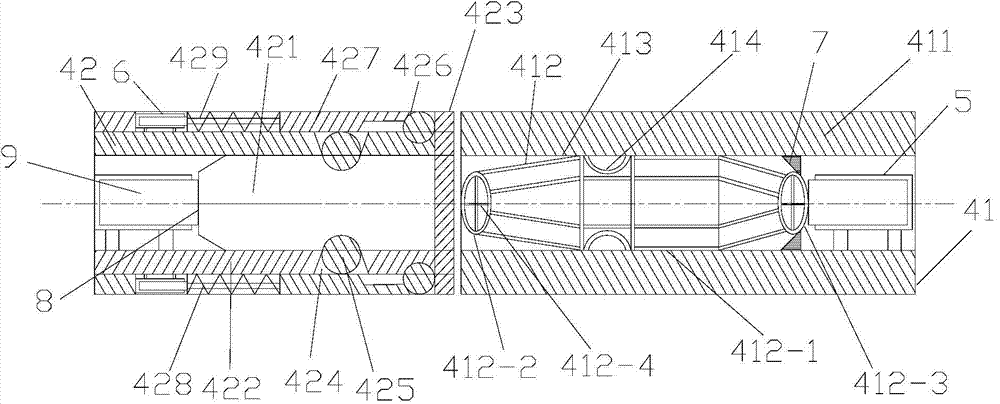

[0022] Such as Figure 1 to Figure 6 As shown, the flexible mechanical connector of the present invention applied between modules of a super large ocean floating structure includes a positive body 41 on the module and a negative body 42 on another module. The positive body 41 includes a positive body shell 411 and the positive central shaft 412 located in the positive body housing 411. The positive central shaft 412 includes a first revolving body, a second revolving body and a central shaft 412-1 connecting the first revolving body and the second revolving body. The end of the body away from the central shaft 412-1 is connected to the first power cylinder 5. The negative body 42 includes a negative carrier 422, a second power cylinder 9 located in the negative carrier 422, and a locking device on the negative carrier 422. The first power cylinder 5 pushes the positive bottom shaft 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com