Hollow glass with outer seal structure

A kind of outer sealing and hollow technology, applied in the direction of parallel glass structure, etc., can solve the problems of complex process, weak sealing, improper handling, etc., to achieve the effect of simple structure and process, simple and reliable sealing, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

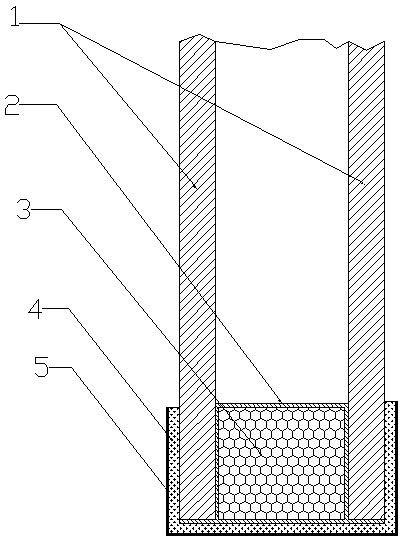

[0015] figure 1 , after filling the aluminum alloy rectangular tube with flash on both sides with desiccant (3), fix it on the inner edge of the glass plates on both sides with double-sided adhesive or instant adhesive; then use hot-melt butyl adhesive Dip all the outer surfaces around the edge of the insulating glass as a whole to form a sealant layer (4); then cover the sealant layer (4) with a cladding layer (5); or directly compound the cladding layer ( 5) The butyl tape completely covers and seals all the outer surfaces around the edge of the hollow glass, thereby producing an insulating glass with an outer sealing structure.

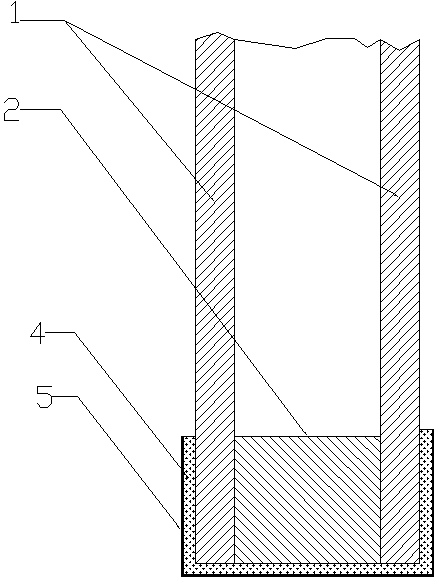

[0016] figure 2 In the process, the inorganic or plexiglass slats are fixed on the inner edges of the glass plates on both sides with double-sided adhesive or instant adhesive; then hot-melt butyl adhesive is used to dip all the outer sides around the edge of the insulating glass to form a seal. glue layer (4); and then wrap the sealant layer (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com