Gas generating furnace

A gas and furnace body technology, applied in the field of combustion furnaces, can solve the problems of poor gas drying effect, difficult cleaning of dust, insufficient combustion, etc., and achieve the effects of good effect, easy cleaning and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

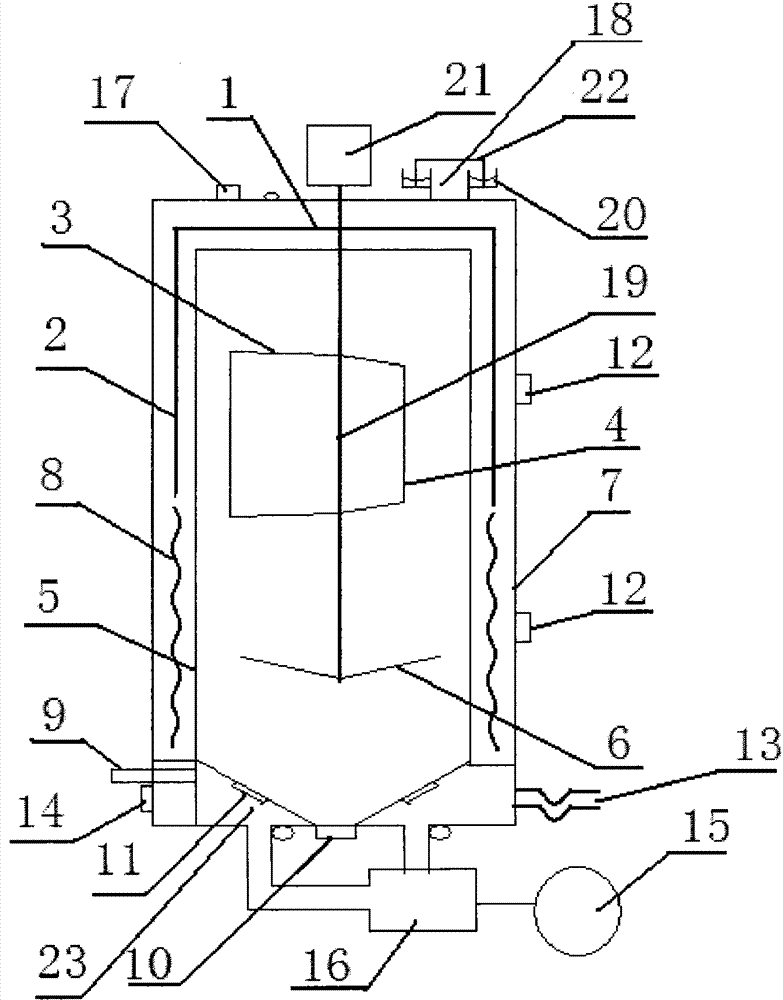

[0021] Such as figure 1 As shown, a gas generating furnace includes a furnace body, the furnace body is provided with an outer cylinder 7 and a middle cylinder 5, and the distance between the top of the outer cylinder 7 and the top of the middle cylinder 5 is 10 cm, so The gas chamber is between the outer cylinder 7 and the middle cylinder 5, and the interior of the middle cylinder 5 is a combustion chamber; the furnace body is provided with a rotating shaft 19, and the rotating shaft 19 is connected to the motor 21 arranged outside the furnace body. , the rotating shaft 19 is provided with a rotating arm 1, the rotating arm 1 is located above the middle cylinder 5, the rotating arm 1 is vertically provided with a scraper 2, and the rotating arm 1 rotates with the rotating shaft 19, which can effectively prevent The dust hangs on the wall. There is a serpentine plate 8 under the scraper rod 2. The high-temperature combustible gas coming out of the middle cylinder contains a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com