A kind of furnace roll preparation method for annealing furnace

A technology for annealing furnaces and furnace rolls, which is applied in the direction of rollers, conveyor objects, transportation and packaging, etc., and can solve the problems of low temperature, difficult forming, and poor anti-nodulation performance of furnace roll cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

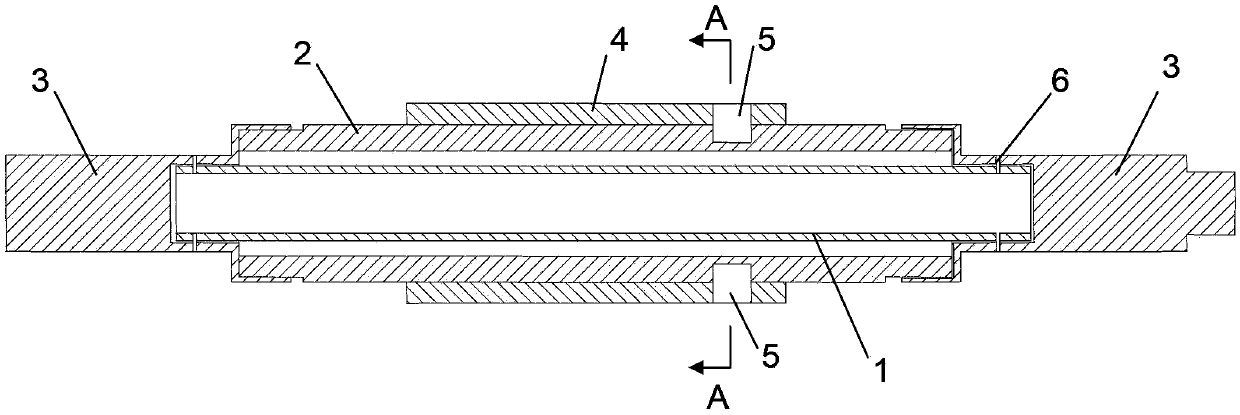

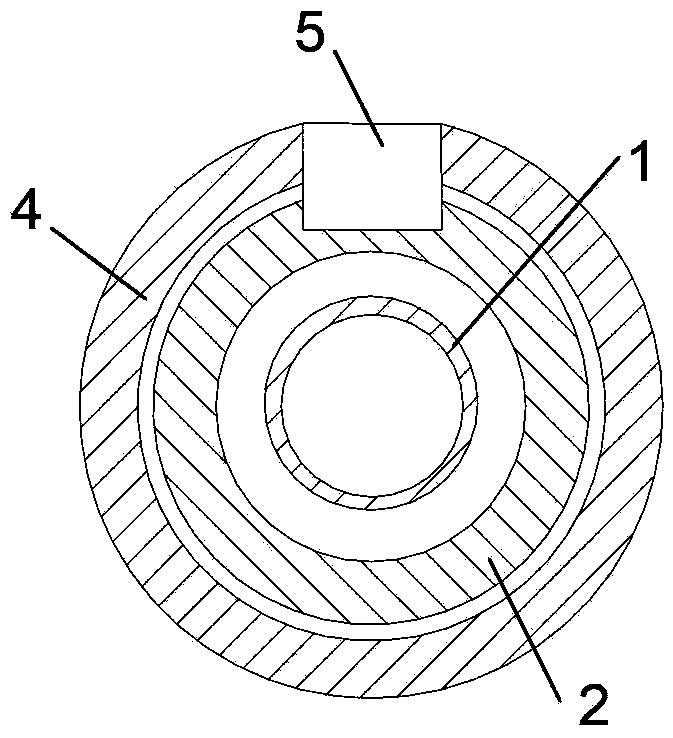

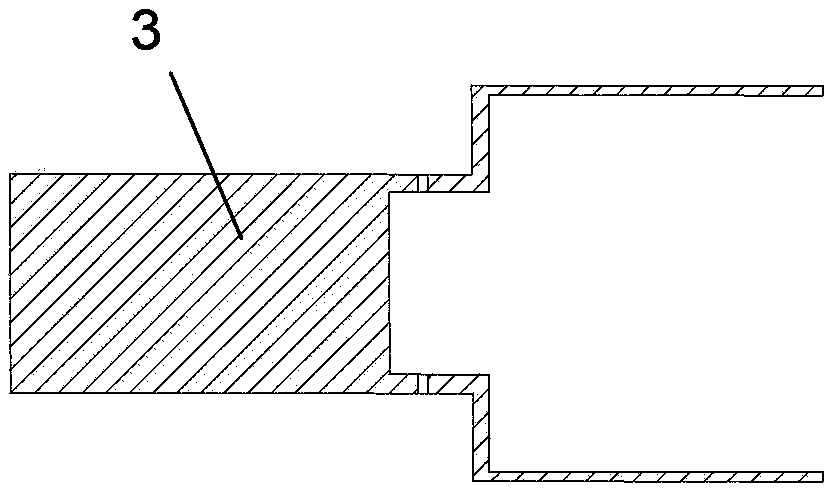

[0029] see Figure 1 ~ Figure 4 As shown, the furnace roll used in an annealing furnace of the present invention includes a steel roll core 1, a roll body 2 of ceramic material, a shaft head 3 of a metal material, and a carbon sleeve 4. The inside of the roll body 2 has a hole, and the roll core 1 penetrates In the inner hole of the roller body 2, the shaft heads 3 are placed on both ends of the roller body 2 and fixed, and the carbon sleeves 4 are placed on the roller body 2 and fixed to the roller body 2 through the ceramic connecting key 5. There is a certain gap between the roller core 1 and the roller body 2 . The shaft head 3 and the end of the roller body 2 are connected and fixed by bolts 6 or liquid glue, and there is a gap between the shaft head 3 and the roller body 2 . The above-mentioned gap can ensure that ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com