Method for producing yarn mercerization and full-width yarn mercerization machine

A technology of mercerizing machine and yarn, applied in the direction of mercerizing yarn/thread/filament, processing textile material carrier, etc., can solve the problems of high labor, low market share, high cost, reduce production cost and improve production efficiency , the effect of less yarn splices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0017] At first, warp 600 60S / 2 pure cotton cheeses into a sheet-shaped warp beam with a traditional warping machine for producing woven fabrics, and by analogy, a total of 10 sheet-shaped warp beams are prepared.

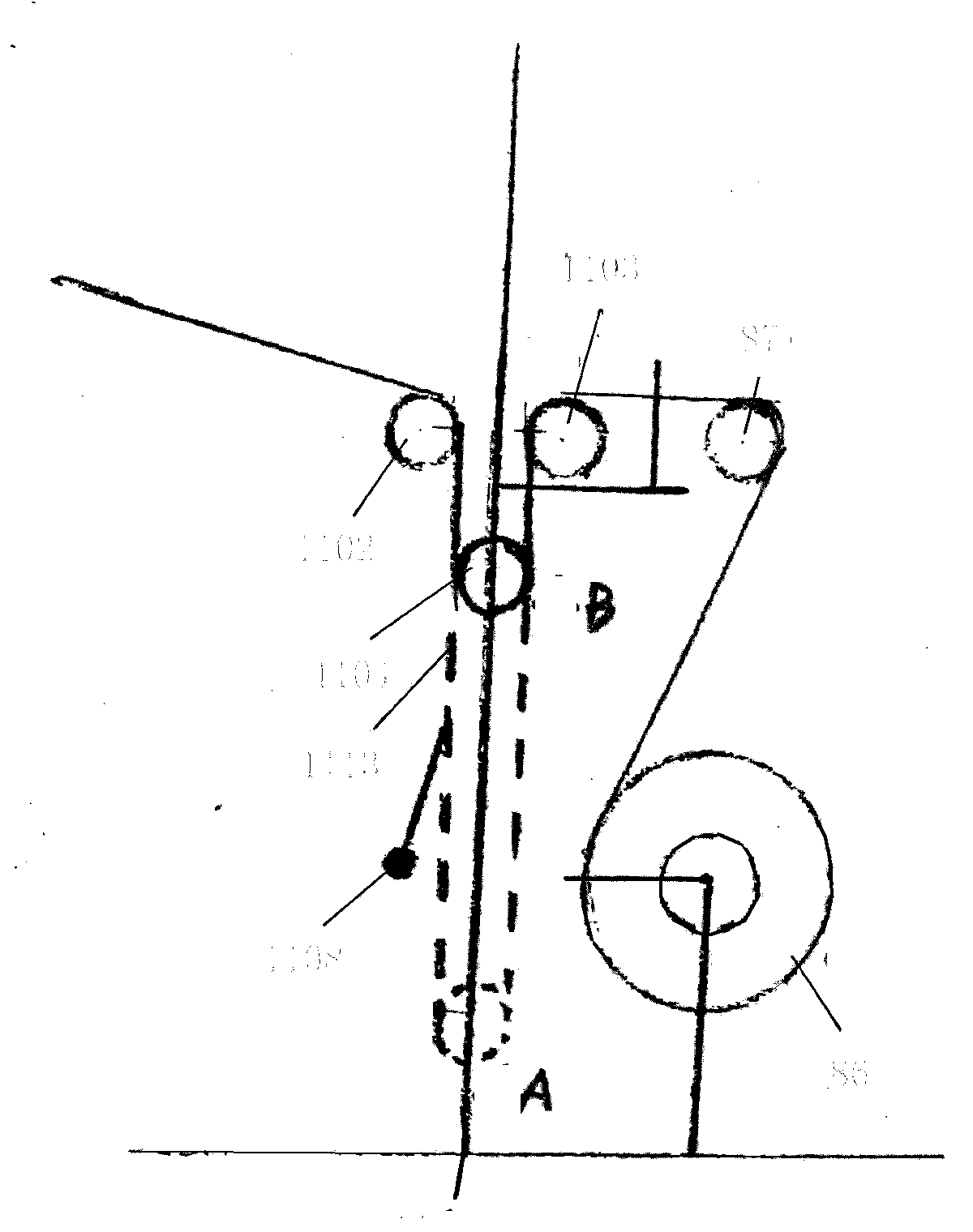

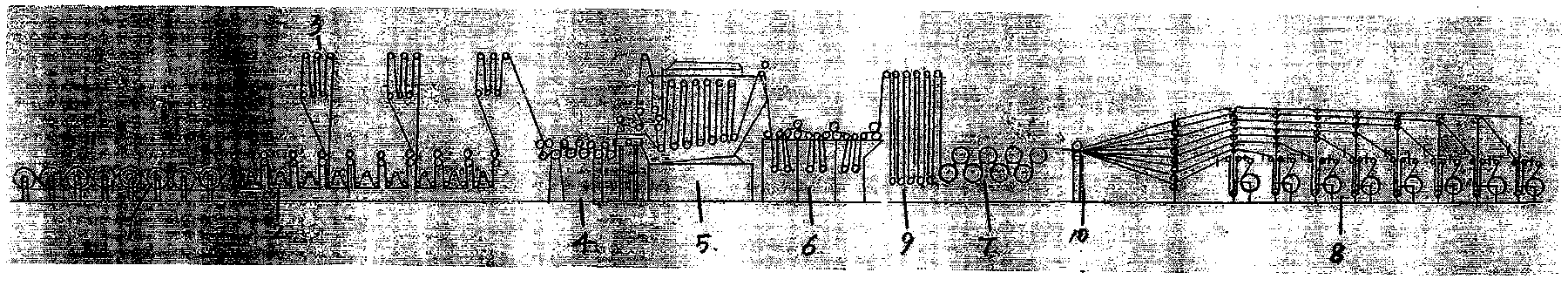

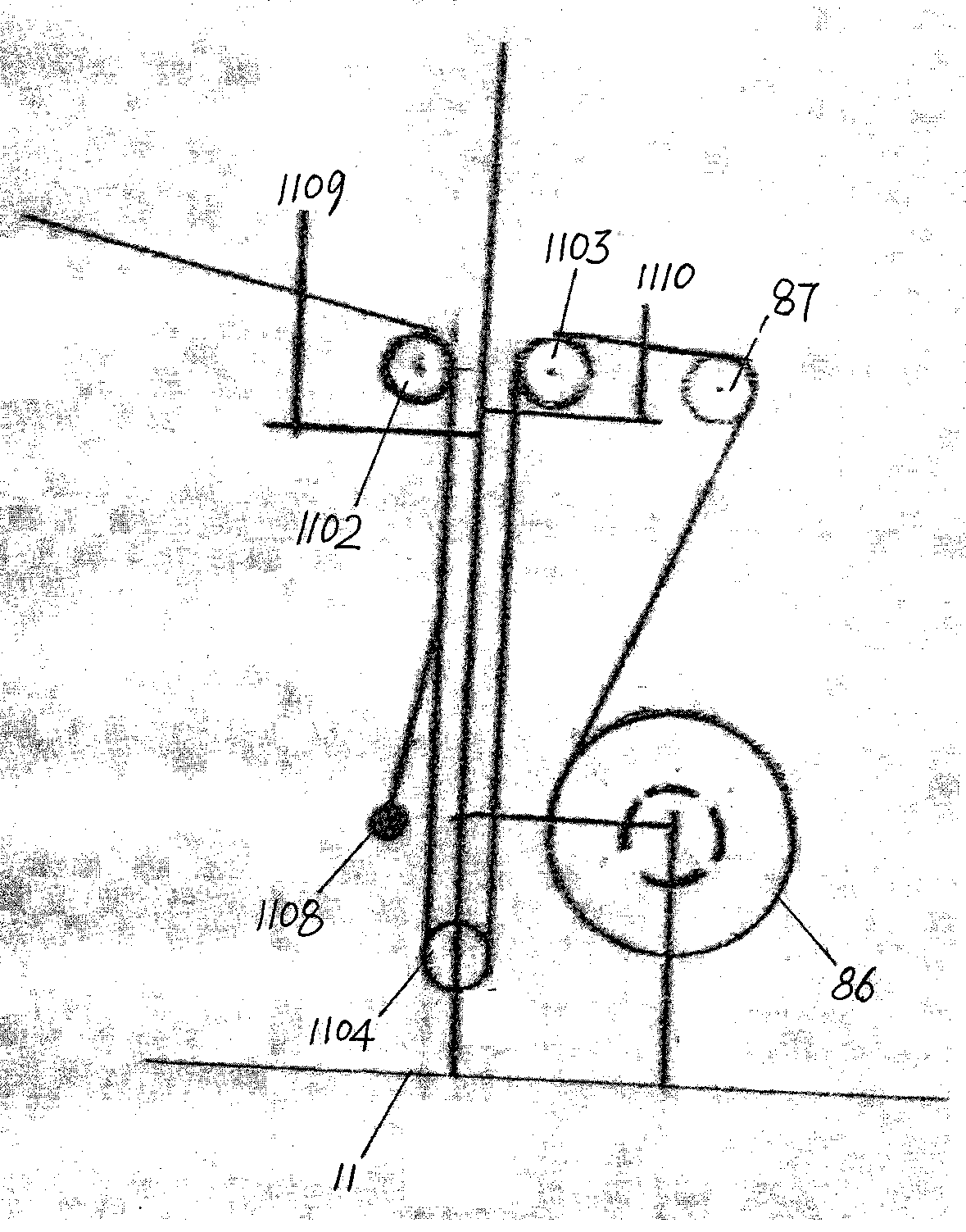

[0018] Next, place the 10 sheet-shaped warp beams (6000 total warps in total) on the sheet yarn creel feeding device 1 respectively, and after passing through the guide roller, the 10 sheet yarns enter the lye dipping tank 2 at the same time, Then through the ventilation frame device 3, let the yarn under the tension of about 50g / thread, and then make the caustic soda solution penetrate into the yarn in the state of multiple dipping and rolling; then enter the washing with soft and hard straight rollers arranged up and down In the alkali removal tank 4, utilize the hot water sprayed in the alkali removal tank 4 and the hot light lye to remove the alkali, and then enter the alkali removal steamer 5 and the neutralization cleaning device 6 to complete the alkali remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com