Ultra-high-speed environmental protection and energy-saving setting machine

An environment-friendly, energy-saving, ultra-high-speed technology, applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc. Outflow loss, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

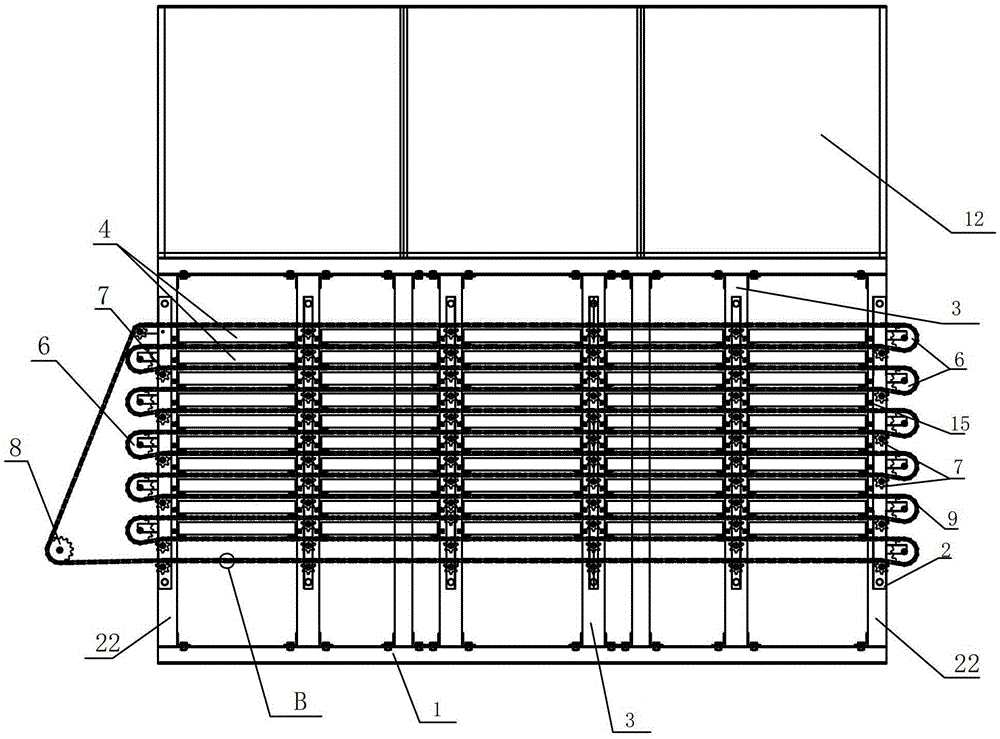

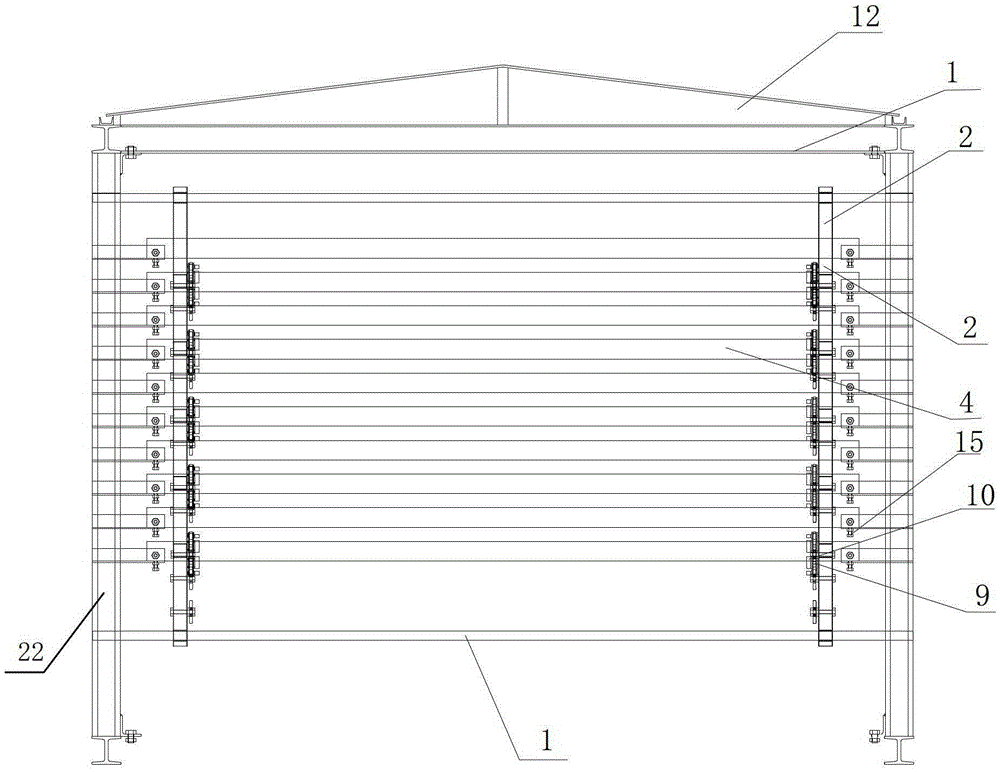

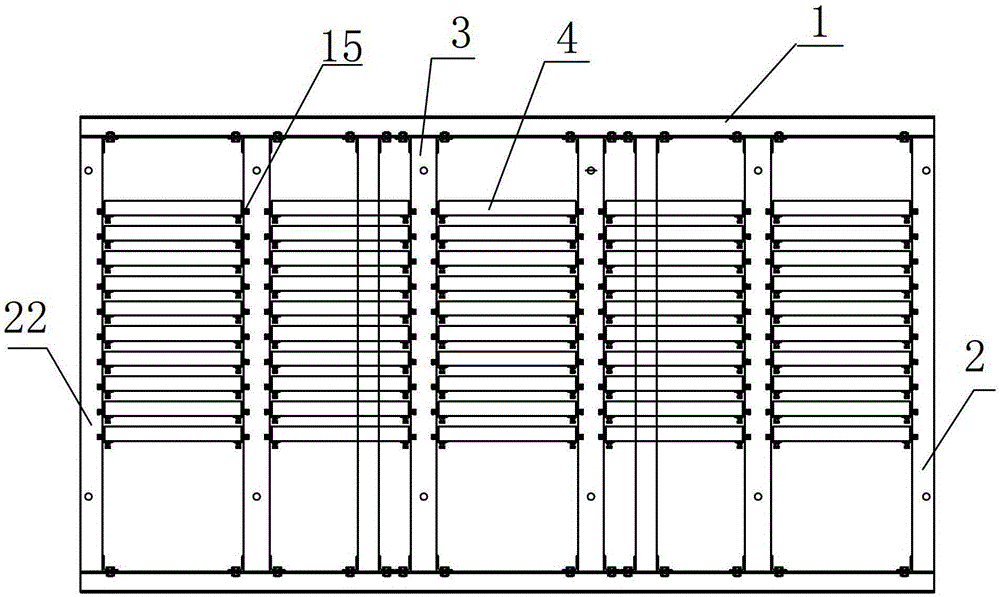

[0050] This embodiment provides an ultra-high-speed environmental protection and energy-saving setting machine, as attached Figure 1~3 As shown, it includes a bracket 1, and intermediate connecting columns 3 are arranged inside the two sides of the bracket 1, and its structure is as attached Figure 13 shown.

[0051] Both sides of the support 1 are provided with vertical connecting columns 22 on both sides, which are used to connect the upper and lower parts of the support 1, and its structure is as follows: Figure 12 shown. Between the middle connecting columns 3 and between the connecting columns 22 on both sides and the middle connecting columns 3, a multi-layer aluminum heat conducting oil tank 4 is arranged, and the heat conducting oil tank 4 is connected to the middle connecting column 3 or the connecting columns 22 on both sides through an oil tank fixing bracket 17. structure as attached Figure 8 As shown, the fuel tank fixing bracket 17 is square, and it is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com