Common drive type rear duct ejector in adjustable mechanism of variable cycle engine

A variable cycle engine and driving technology, which is applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems of large cumulative error, many connecting rods, and many actuators, so as to reduce adverse effects and prevent jamming Phenomenon, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

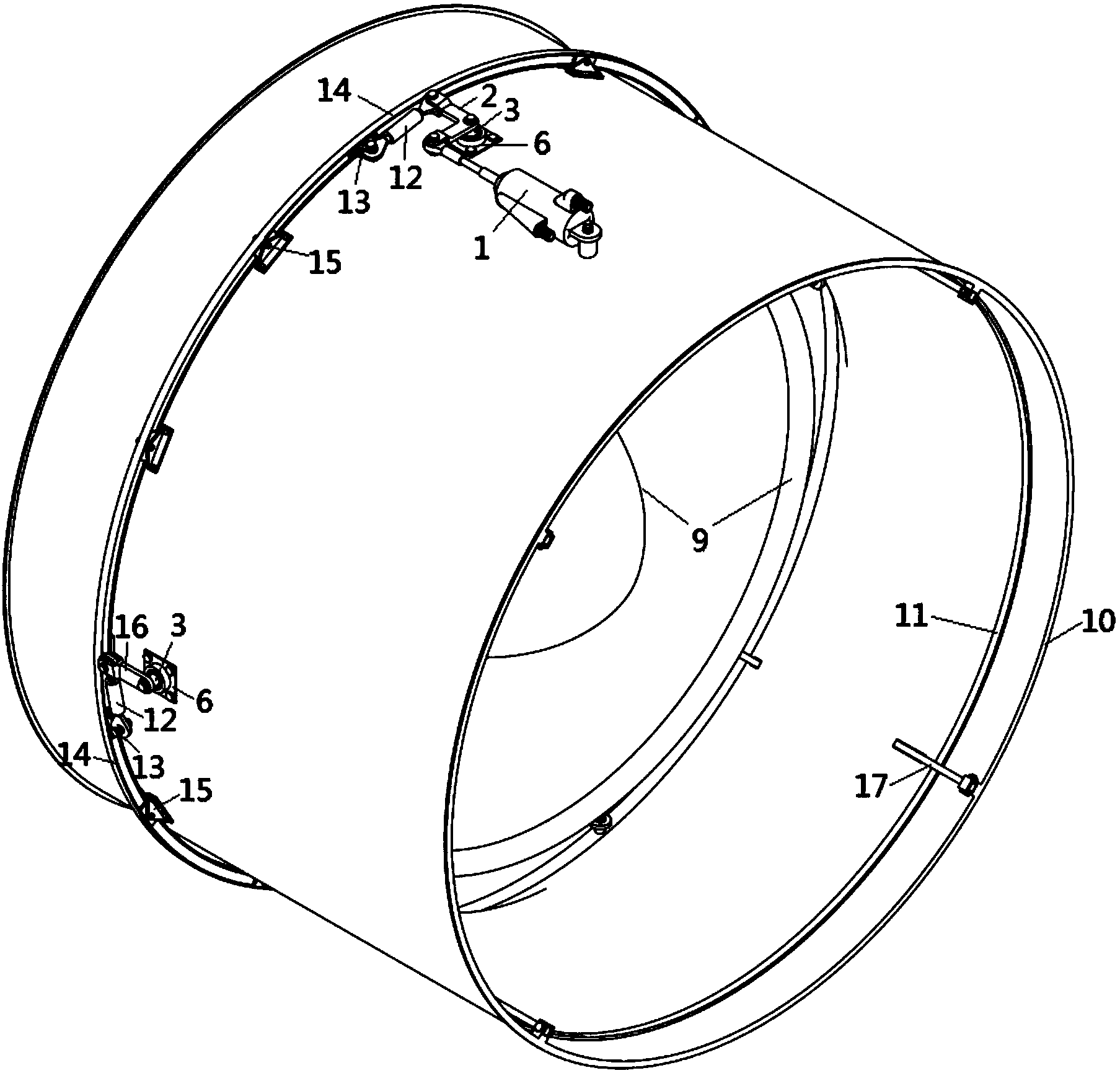

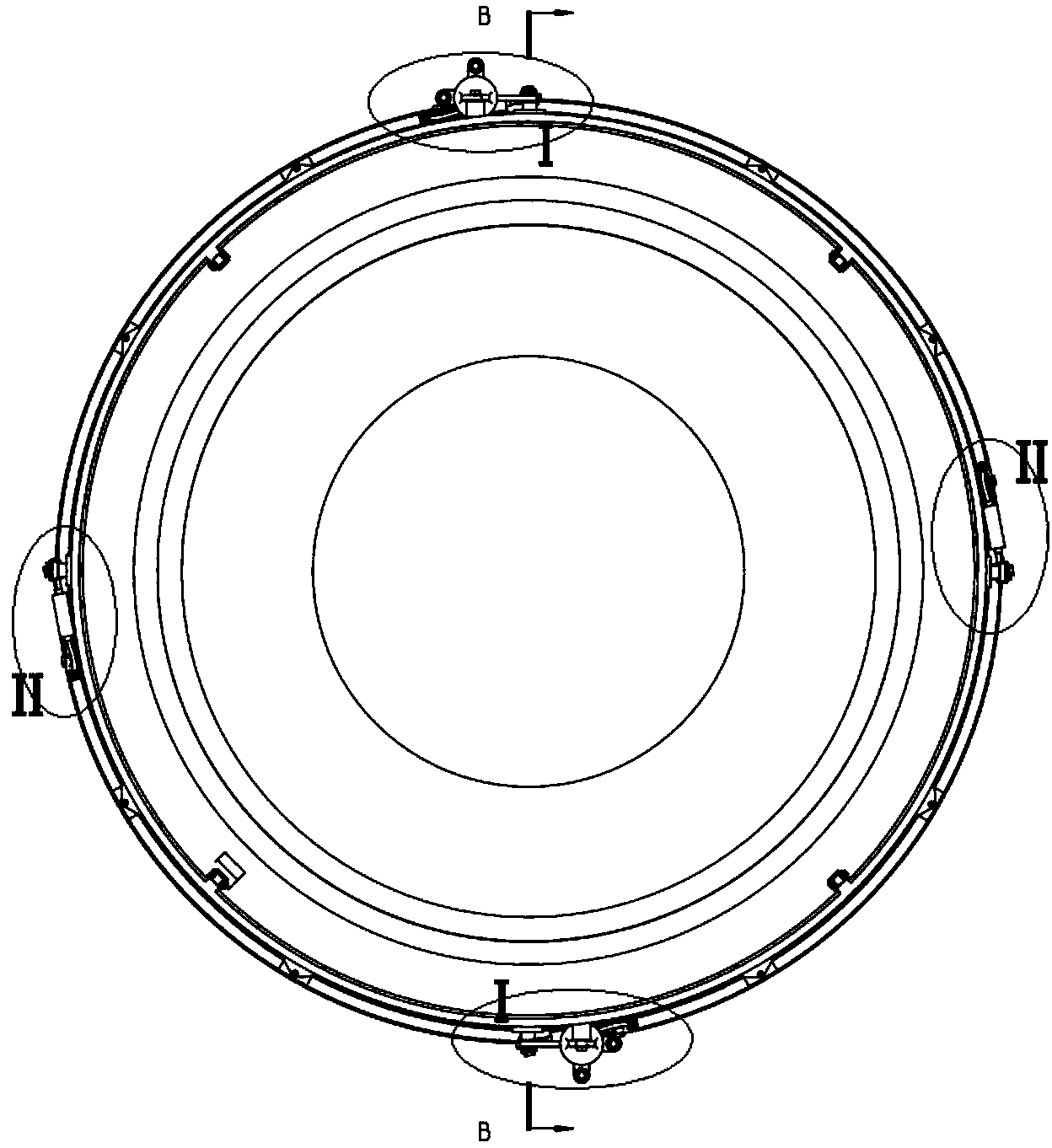

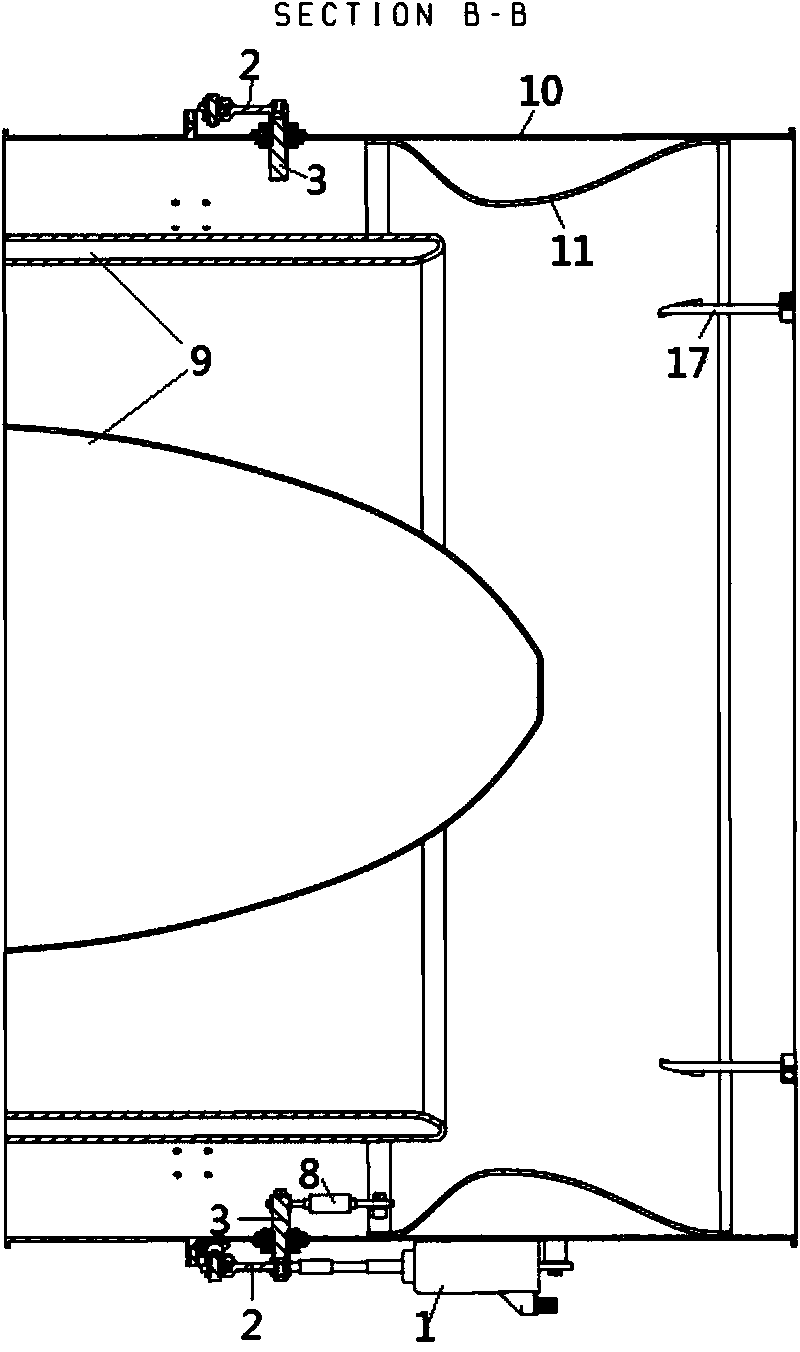

[0059] Such as figure 1 , Figure 2a , Figure 2b , Figure 3-5As shown, the device of the present invention consists of a cylinder 1, a double arm connecting arm 2, a rotating shaft 3, a sleeve 4, a bearing 5, a bearing seat 6, a retaining ring 7, a valve body connecting rod 8, an inner casing 9, and an outer machine Cassette 10, valve body 11, synchronous ring connecting rod 12, synchronous ring connecting hinge seat 13, synchronous ring 14, synchronous ring support 15, single-arm connecting arm 16, linear bearing guide rail 17, linear bearing 18, linear bearing fixing frame 19 composition.

[0060] The overall layout of the device is as follows figure 1 , Figure 2a , Figure 2b As shown, the synchronous ring 14 is installed and positioned on the outside of the casing 10 through the synchronous ring support 15, and the synchronous ring 14 is connected to the connecting arms (double-arm connecting arm 2 and single-arm connecting arm 16) in four places: in area I, two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com