Product outer surface defect image acquisition device based on machine vision

An image acquisition device and machine vision technology, applied in the direction of optical testing flaws/defects, can solve the problems of difficult system debugging, complex mechanical structure, large data processing volume, etc., and achieve convenient installation and debugging, easy operation, and small data processing volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

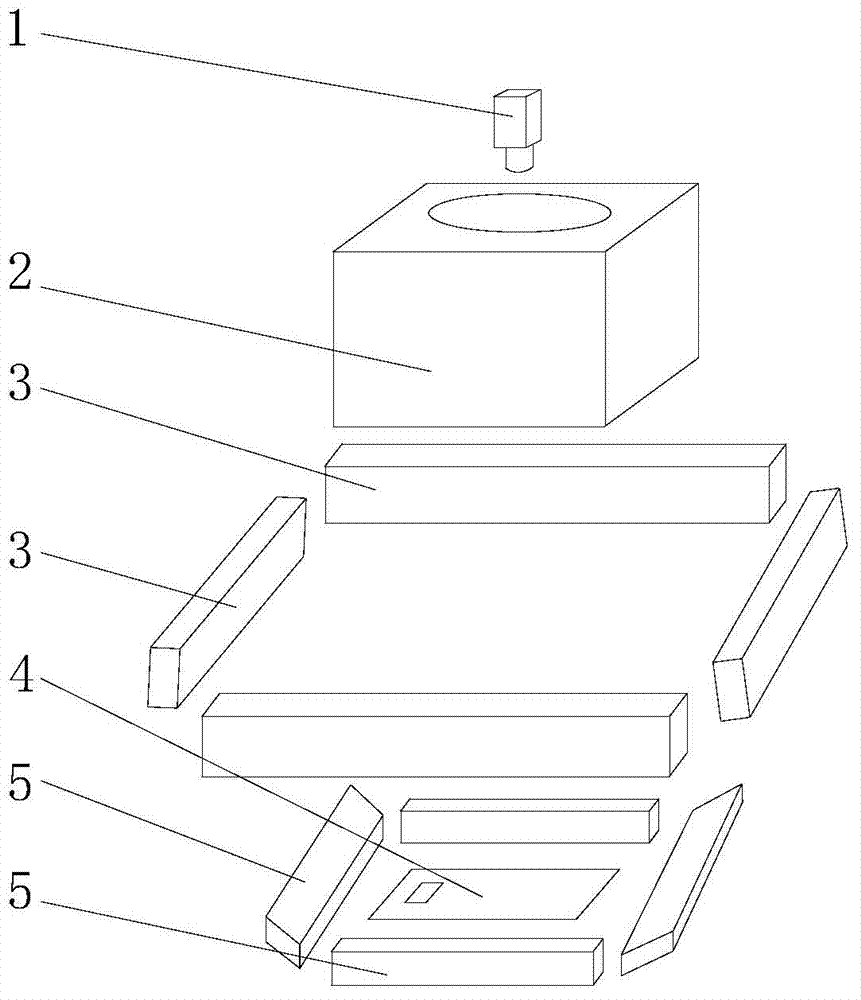

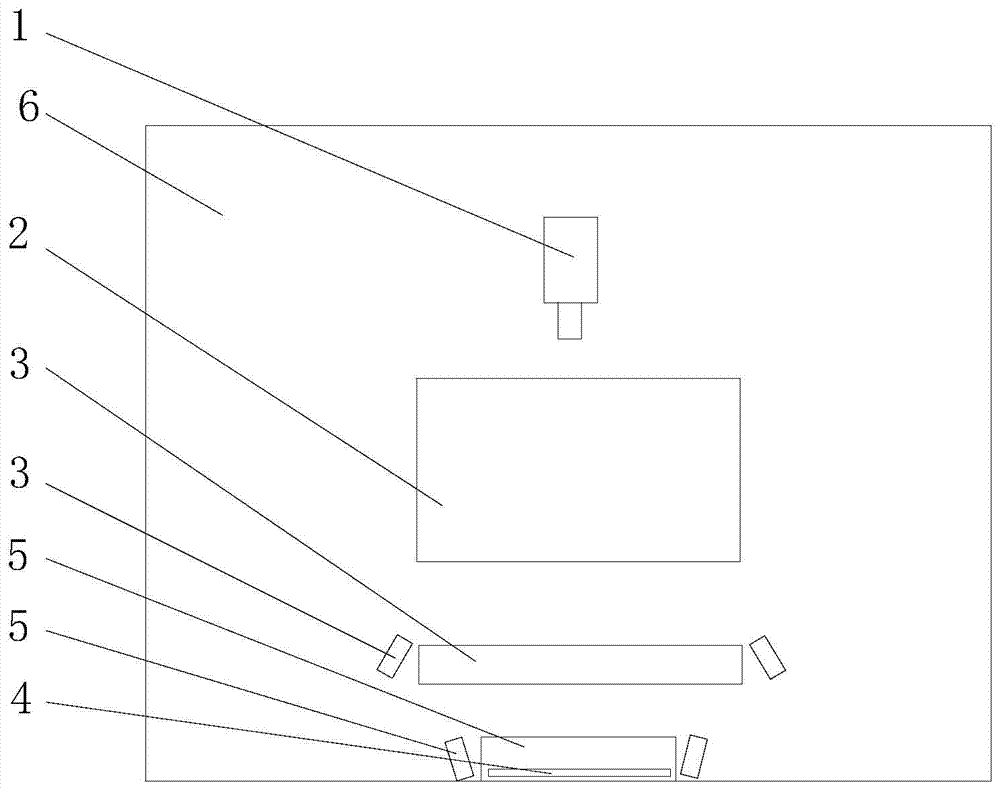

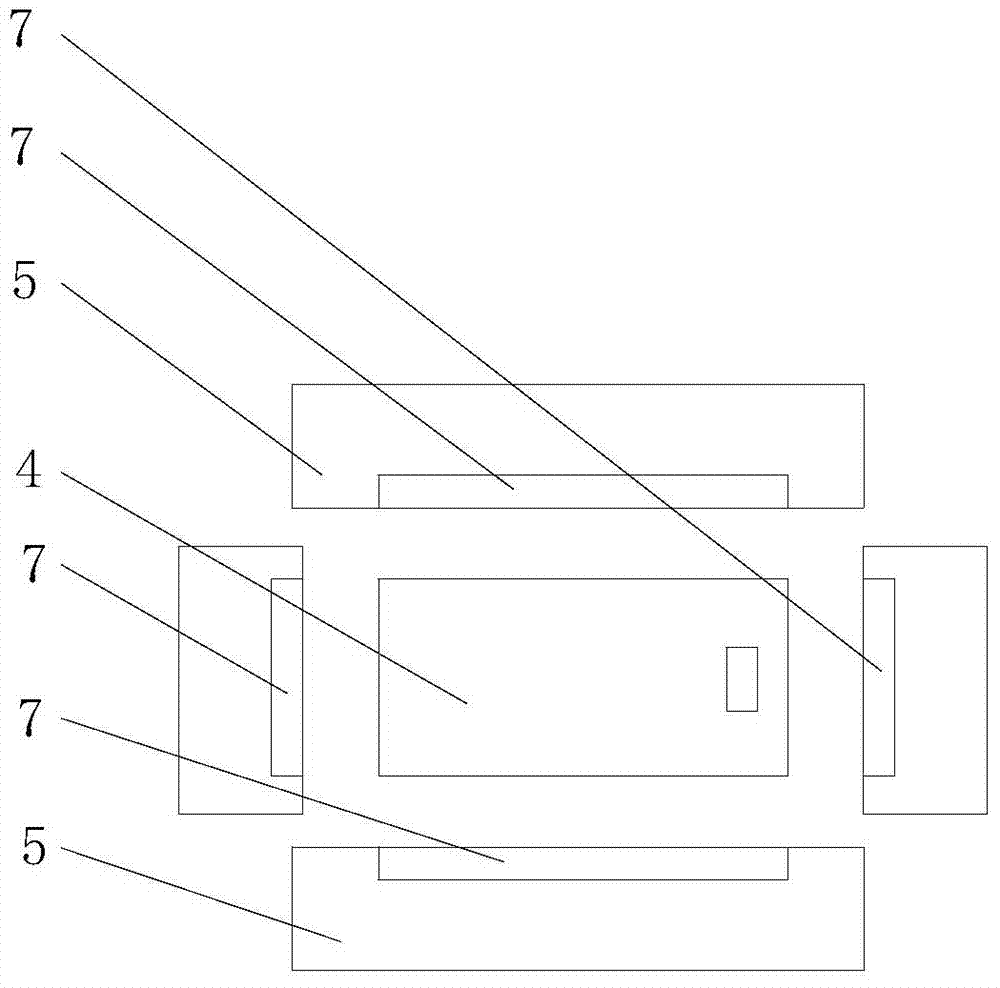

[0023] Such as Figure 1-3 As shown, a product surface defect image acquisition device based on machine vision includes a product to be inspected 4, a camera 1 corresponding to the product to be inspected 4, a lens 5 arranged around the product to be inspected 4, and a supplementary light source , a light-tight hood 6 and a light source controller connected to the supplementary light source, the product 4 to be detected, the camera 1, the eyeglass 5, the light source controller and the supplementary light source are arranged in the light hood 6 to facilitate the adjustment of the light. Also be provided with the sensor that controls camera 1 to take pictures.

[0024] There are four lenses 5 and they are all inclined upwards at 45°. The four lenses 5 surround the product 4 to be tested respectively, and the lenses 5 are concave mirrors or plane mirrors.

[0025] The supplementary light source includes a coaxial light source 2 and four bar-shaped light sources 3, the coaxial l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com