A wind screen device for battery plate curing room

A plate curing and battery technology, applied in the field of curing room, can solve the problems of prolonging the curing cycle, reducing the quality of the plate, weakening the direct impact, etc., and achieve the effect of improving the uniformity of air supply, shortening the curing cycle, and improving the quality of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

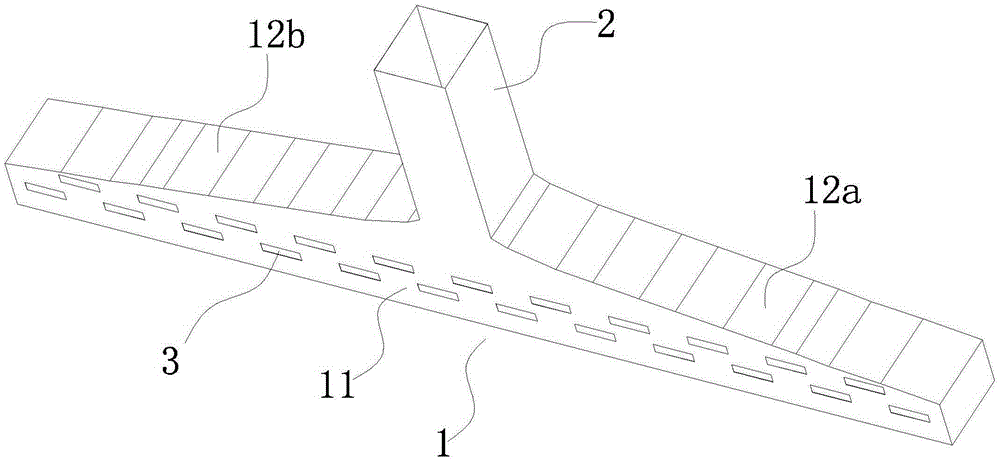

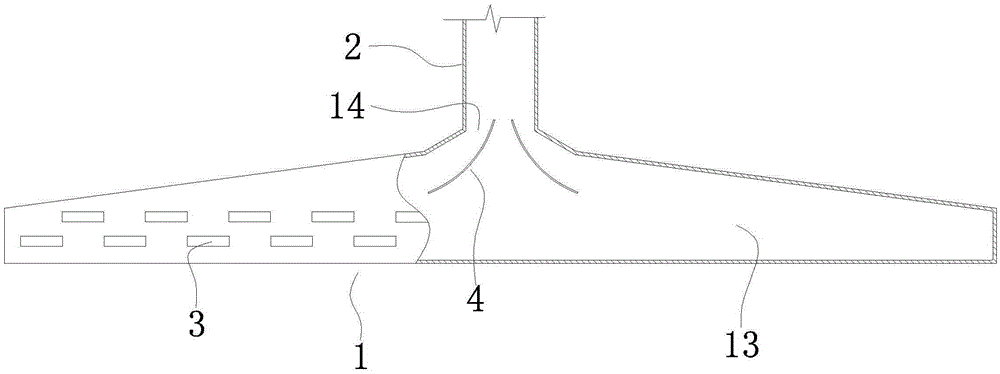

[0030] Example 1: as figure 1 , figure 2As shown, an air distribution screen device for a battery plate curing chamber includes an air distribution box 1 with a closed cavity inside, an air inlet 14 arranged in the middle of the top surface of the air distribution box and communicated with the inner cavity of the air distribution box, and an air inlet 14 Connected air supply duct 2. The air distribution box is surrounded by six air distribution boards, front, rear, left, right, upper and lower. The front, rear, left and right air distribution panels are vertically distributed, and the front and rear air distribution panels are parallel to each other, and the left and right air distribution panels are parallel to each other. The lower air distribution panel is set horizontally. The upper cloth plate is composed of a left upper cloth plate 12a and a right upper cloth plate 12b located on the left and right sides of the air inlet. The upper left cloth plate gradually extends...

Embodiment 2

[0037] Embodiment 2: The remaining structures in this embodiment refer to Embodiment 1, and the differences are:

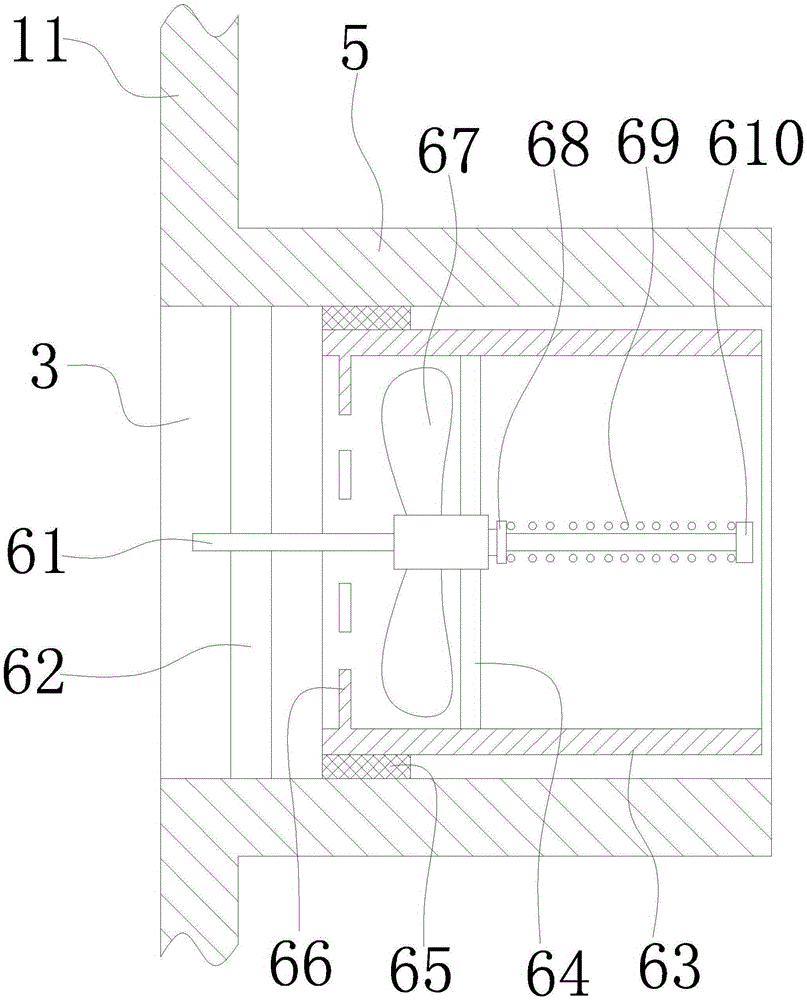

[0038] like image 3 , Figure 4 As shown, each air supply port 3 is circular, and the edge of each air supply port is respectively provided with a guide sleeve 5 extending outward. The deflector is located on the outer side of the front air distribution plate. The guide sleeve is arranged horizontally, and the cross section of the guide sleeve is circular. A self-adaptive wind adjustment device is respectively arranged in each guide sleeve. The adaptive wind adjustment device includes an adaptive adjustment sleeve 63 coaxially arranged in the guide sleeve, a main shaft 61 and an impeller 67 rotatably arranged on the main shaft, and the impeller is located in the adaptive adjustment sleeve. The main shaft rod is fixed on the inner wall of the guide sleeve through the first connecting rod 62, and the first connecting rod is located between the inner cavity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com