Ventilation duct and compost ventilation device

A technology for ventilation pipes and ventilation devices, which is applied in the direction of fertilization devices, pipe components, organic fertilizers, etc., and can solve the problems of uneven ventilation in the composting system and non-vertical airflow axes of the air ducts, so as to improve the uniformity of air supply and reduce the The effect of ventilation dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Further description will be given below through the embodiments shown in the accompanying drawings.

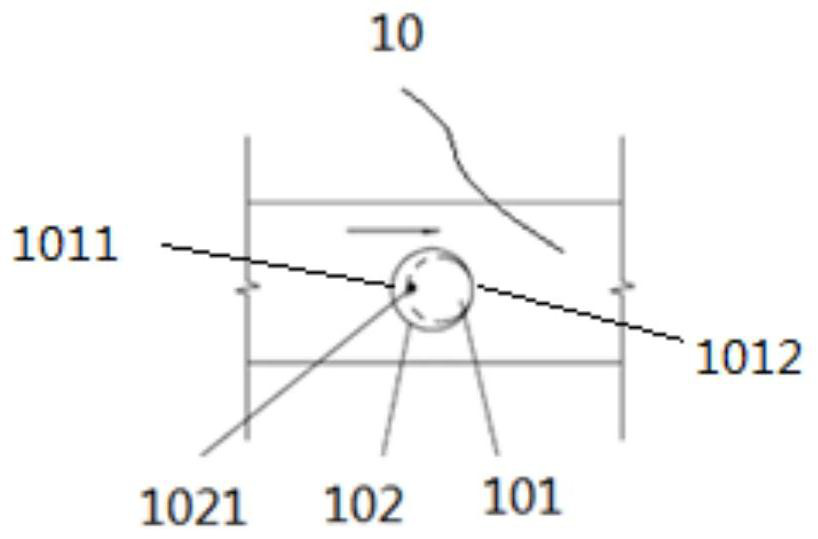

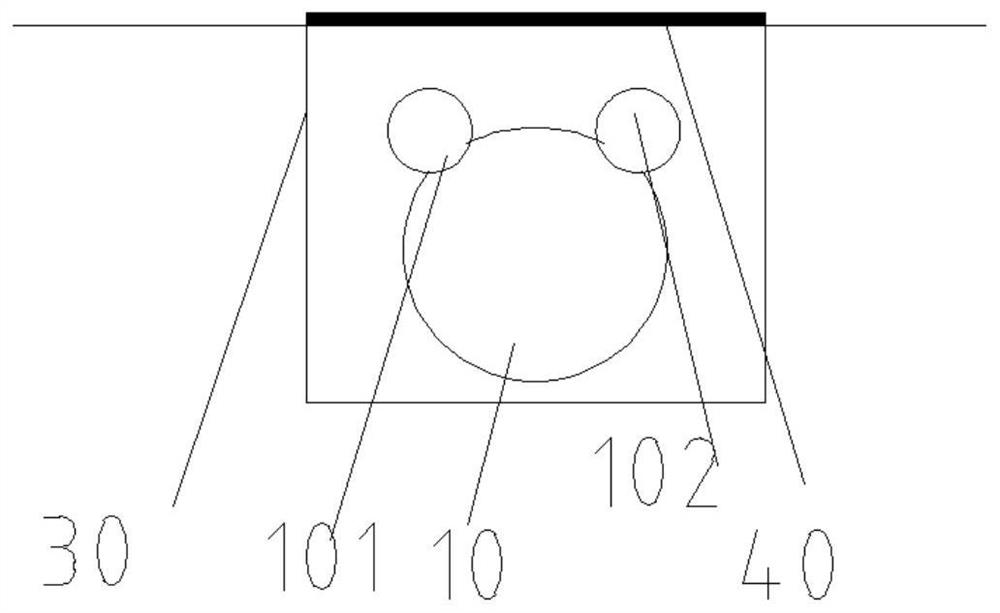

[0059] The ventilation pipe 10 of this embodiment is laid in the aeration tank 30, and the perforated plate 40 is laid on the tank to separate the pile body from the ventilation pipe. Ventilation duct 10 top offers ventilation hole 101, and baffle plate 102 is added on the ventilation hole 101, and when ventilating, baffle plate 102 is opened, as image 3 shown.

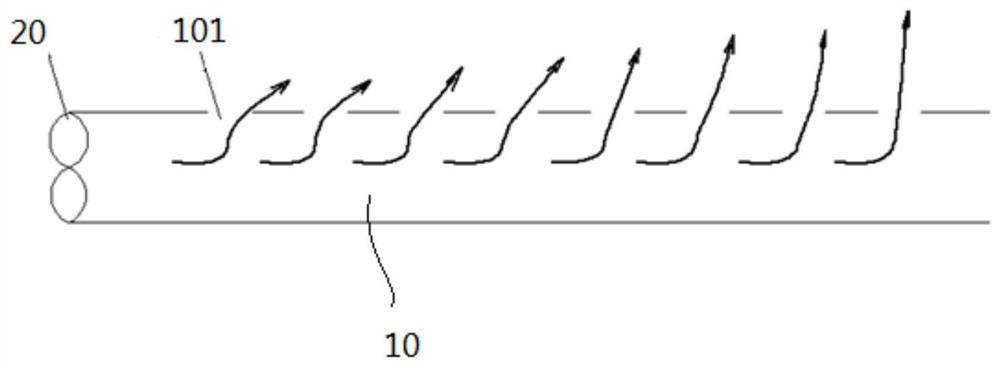

[0060] The ventilation ducts commonly used in the existing composting production, at the beginning of the duct, the flow velocity in the duct is high, and the outlet flow from the orifice is deflected to the axial direction of the duct, resulting in a weak ventilation area at the beginning of the duct; , so that the air velocity in the end area is too large, such as figure 1 shown.

[0061] Therefore, in order to improve the structure of the above-mentioned ventilation duct, on the basis of the existing com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com