Motor rotor and motor

A technology of motor rotor and inner iron core, applied in the field of motors, can solve the problems of few applications and immature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

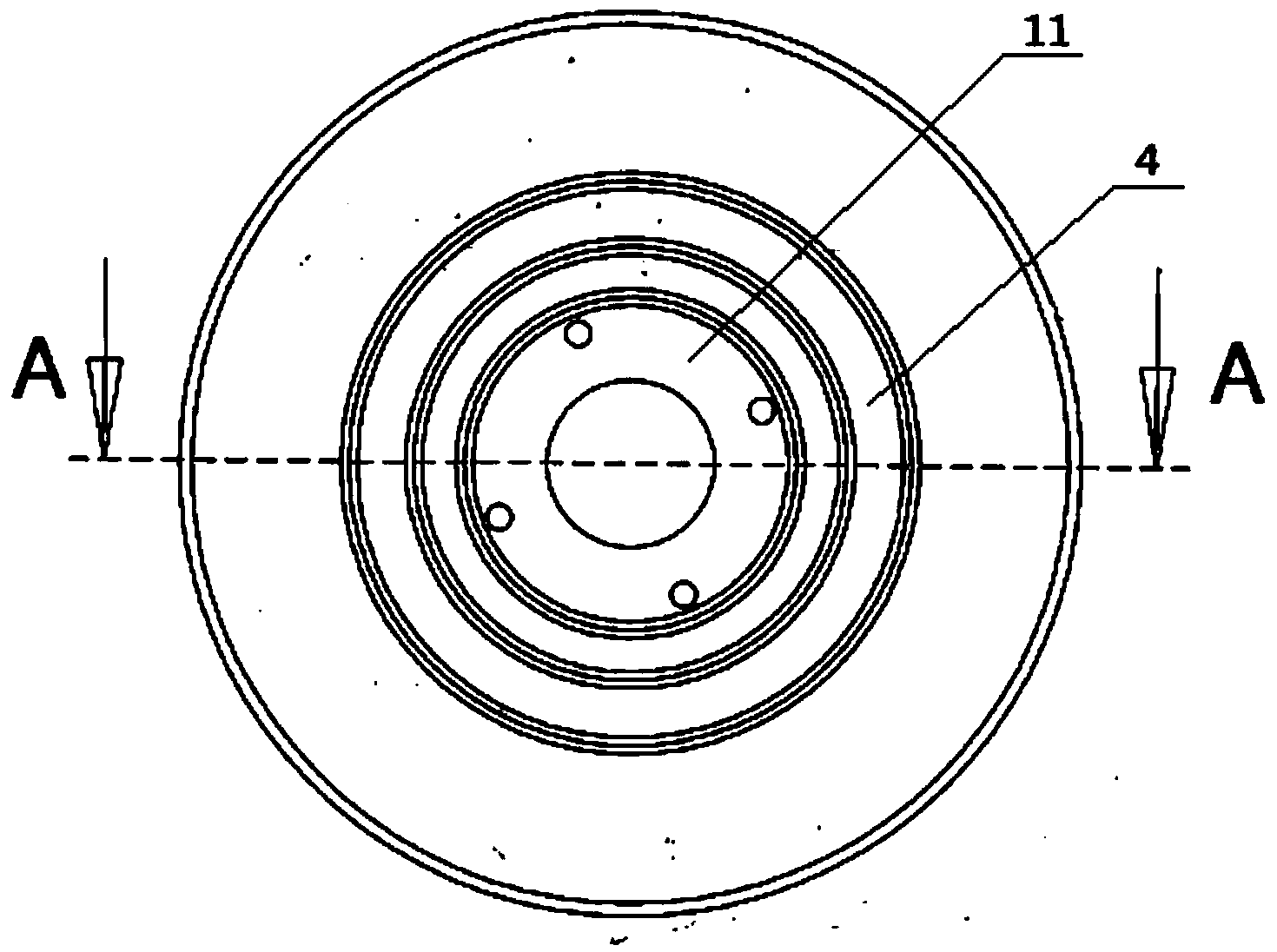

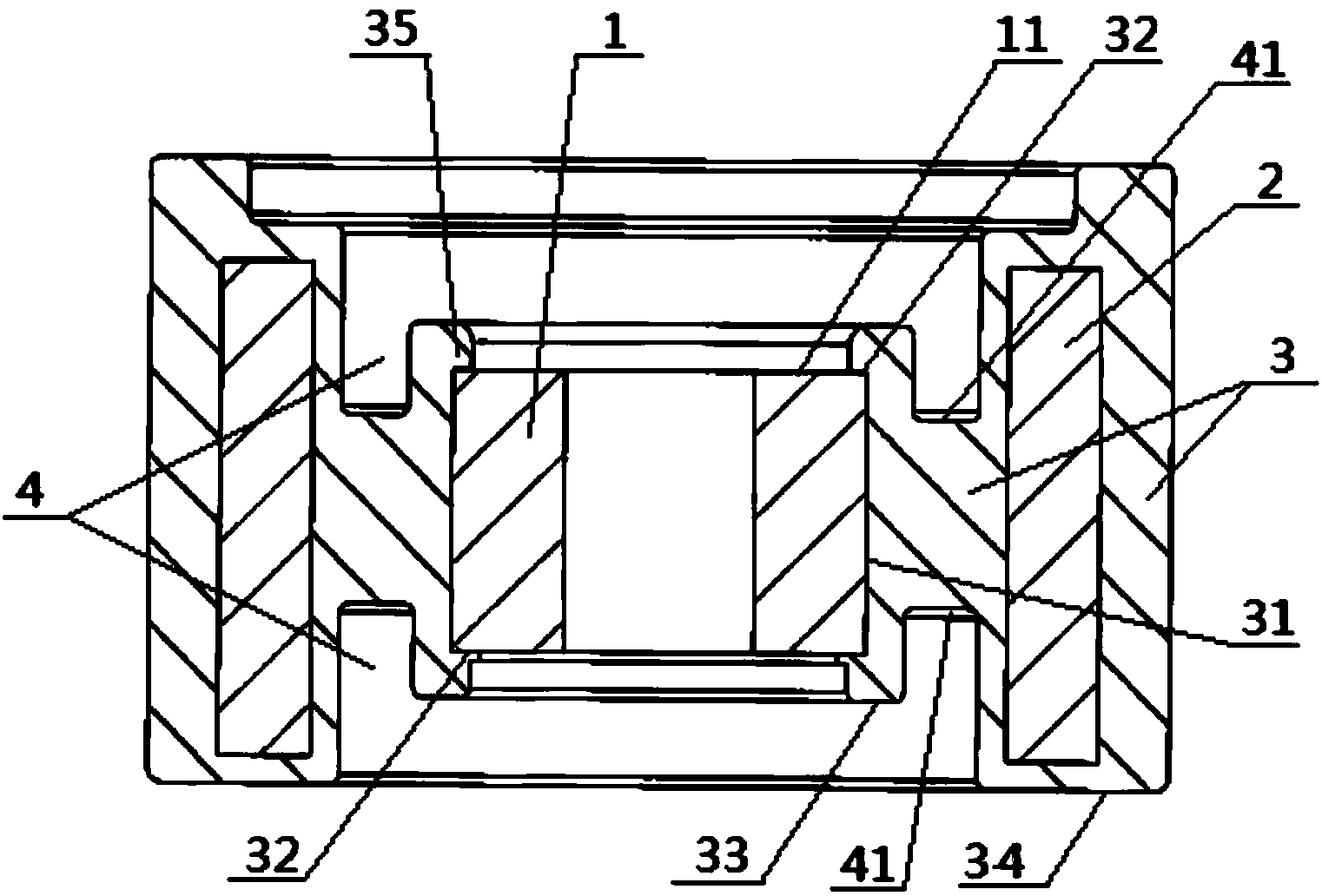

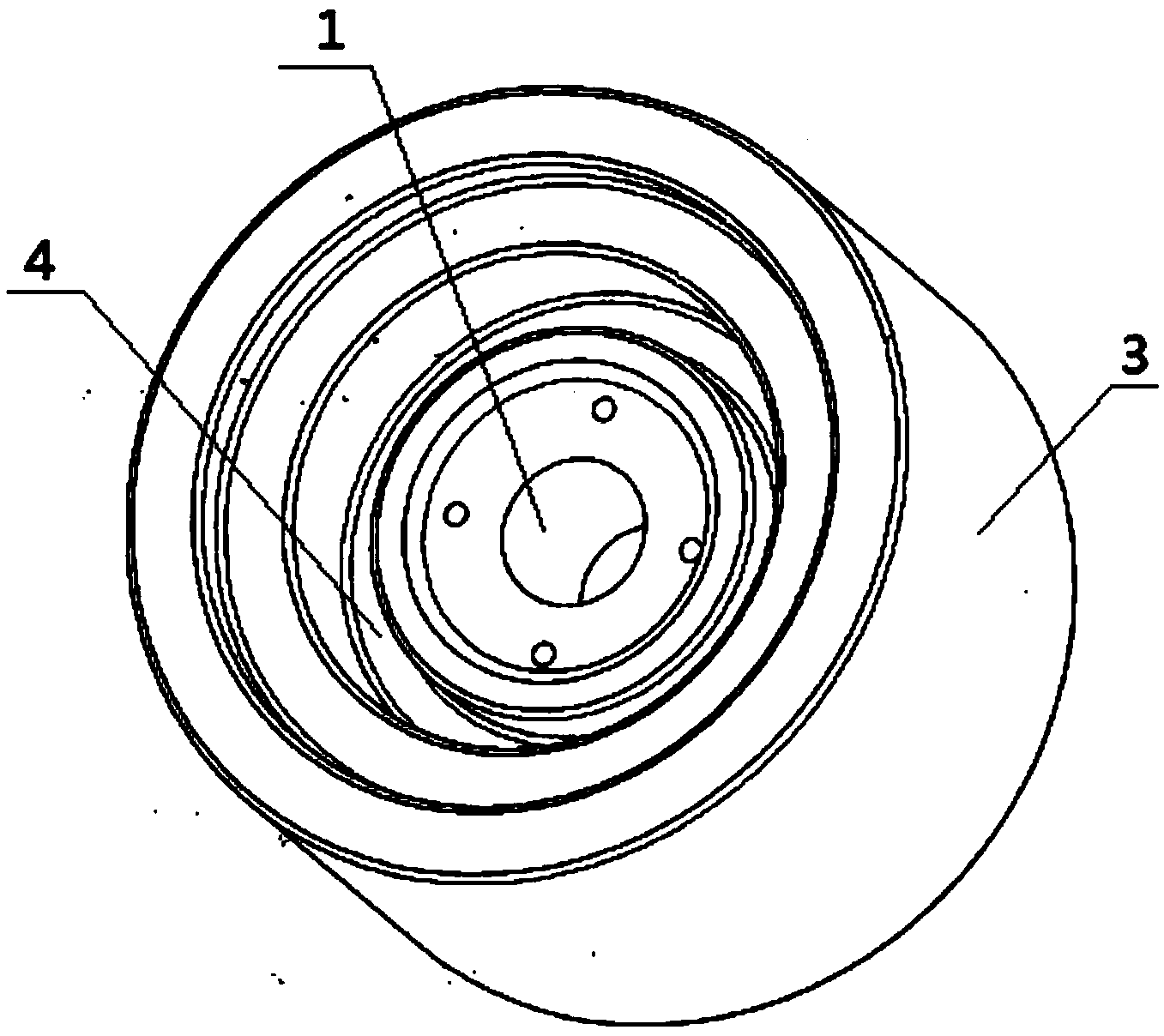

[0020] Such as Figure 1 to Figure 5 Shown is an embodiment of the motor rotor of the present invention, which is applied to a motor, wherein figure 2 and Figure 5 exactly the same, both figure 1 The A-A sectional view in the middle is divided into two for the sake of clear marking. The motor rotor of the present invention includes an inner iron core 1 and an outer iron core 2 arranged concentrically. Both the inner iron core 1 and the outer iron core 2 can be of an integral iron core or laminated structure. The inner iron core 1 and the outer iron core 2 are fixed by the insulating framework 3, the thickness h of the inner iron core 1 and the thickness H of the outer iron core 2 satisfy the following relationship: 0.5≤h: H figure 2 The upper and lower symmetrical structures shown in , the symmetrical structure here only expresses the relative positional relationship between the inner iron core 1 and the outer iron core 2, and does not involve the insulating skeleton 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com