Method for correcting phase sequence of power line of permanent magnet synchronous motor driver of electric car

A technology of permanent magnet synchronous motor and correction method, which is applied in the direction of motor generator control, control of electromechanical brakes, electronic commutation motor control, etc. Achieve the effect of avoiding burning accidents, reducing line connection and phase sequence testing, and improving the efficiency of R&D and maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

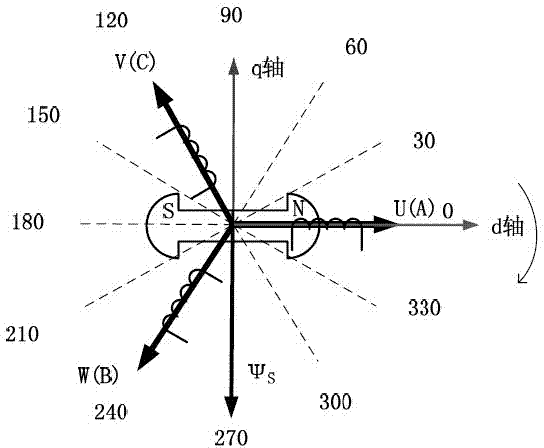

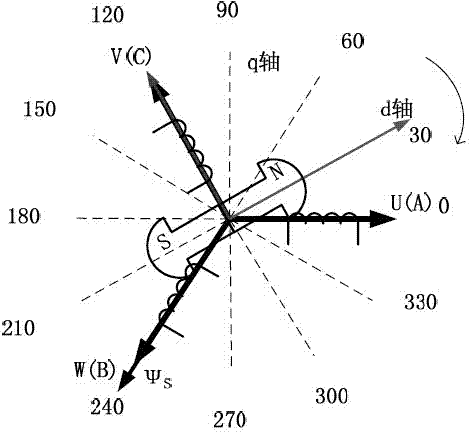

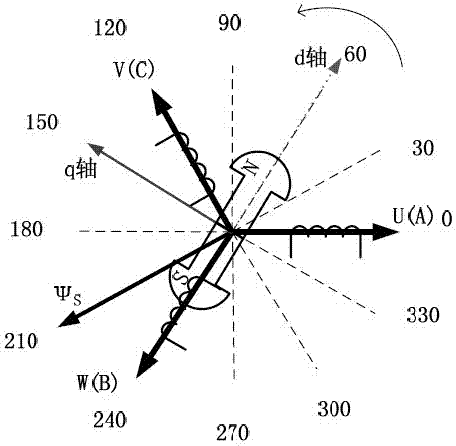

[0044]In the method steps of the present invention, it is necessary to perform certain corrections to the collected rotor electrical angles according to the connection phase sequence of the driver and the motor power line. In order to further understand the above correction method, the specific correction method of the rotor electrical angle is deduced below through the interaction of the rotor magnetic field and the stator magnetic field of the permanent magnet synchronous motor.

[0045] The derivation process of the rotor electrical angle correction method:

[0046] The drive power line terminals include terminal A, terminal B, and terminal C, the three-phase permanent magnet synchronous motor power line terminals include terminal U, terminal V, and terminal W, and the driver power line terminals are connected to the three-phase permanent magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com