Rotary electric machine

A technology for rotating electrical machines and power supply terminals, applied in electrical components, electromechanical devices, electrical components, etc., can solve the problems of large-scale equipment and high manufacturing costs, and achieve the effect of small occupied space and reduced manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, a rotating electrical machine according to an embodiment of the present invention will be described based on the drawings.

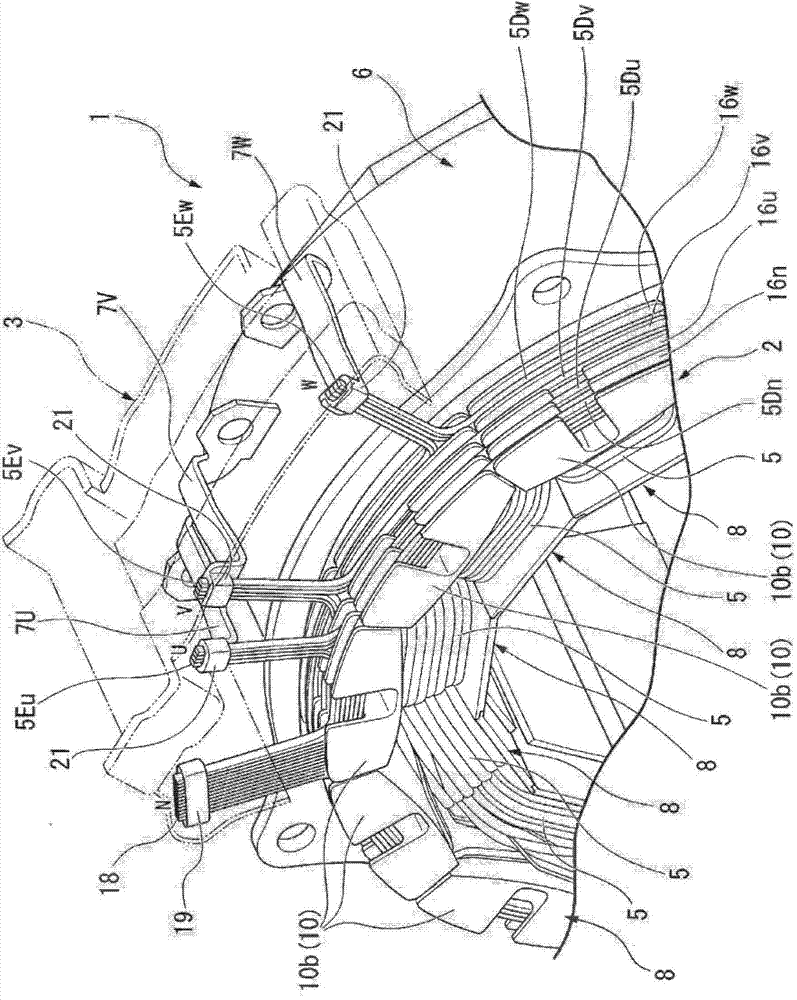

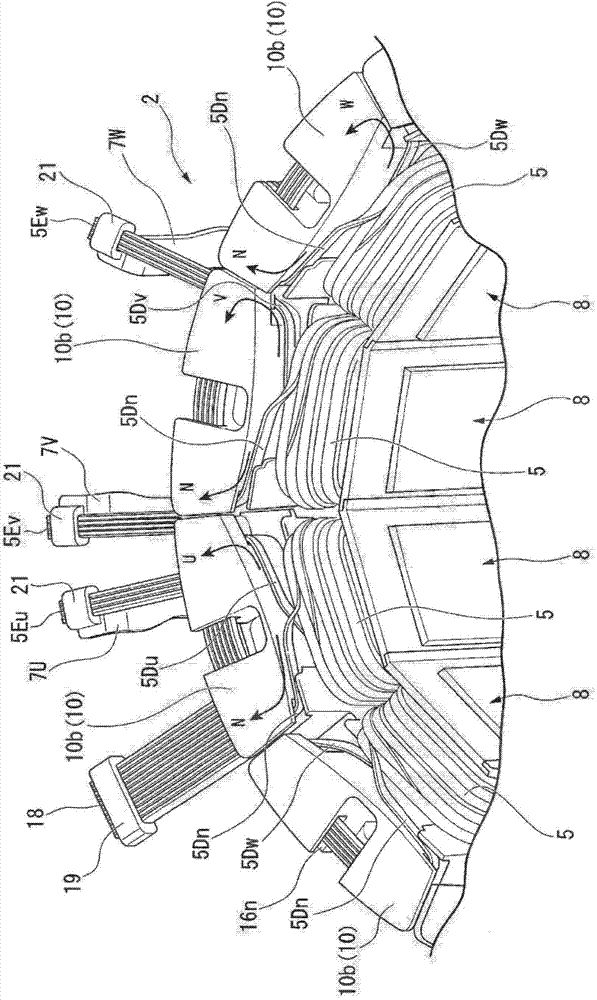

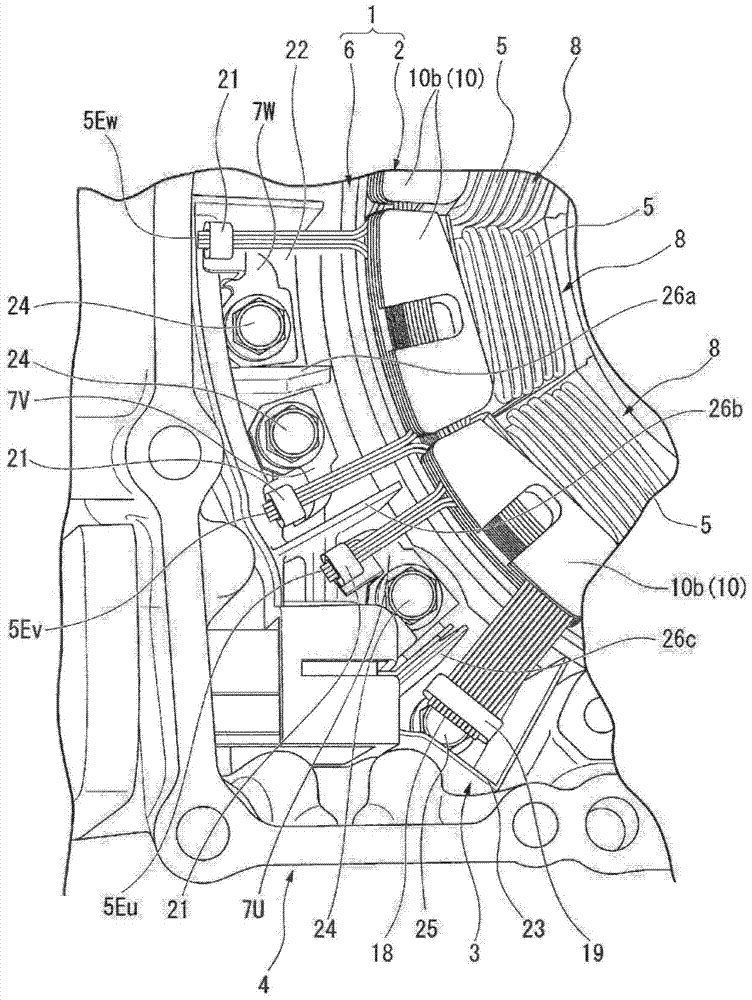

[0055] figure 1 It is a figure which shows the stator 1 incorporated in the electric rotating machine of this embodiment. figure 2 It is a figure which shows the single body of the stator core 2 of the stator 1. image 3 It is a figure which shows the state which assembled the stator 1 and the terminal block 3 in the case 4.

[0056] The rotating electrical machine of this embodiment is a three-phase AC type rotating electrical machine used for vehicle drive and regenerative power generation of an electric vehicle or a hybrid vehicle, and a rotatable rotor (not shown) is disposed inside an annular stator 1 . . The rotor is coupled to an axle of the vehicle via a reduction mechanism or the like.

[0057] The stator 1 includes: an annular stator core 2 on which a plurality of coil wires 5 are attached in salient-pole concentrated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com