Assembly structure of microwave oven

An assembly structure and microwave oven technology, applied in the field of microwave ovens, can solve the problems of unstable connection state, lost screws, low assembly efficiency, etc., and achieve the effects of easy implementation of assembly operations, stable connection state, and maintenance of connection state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

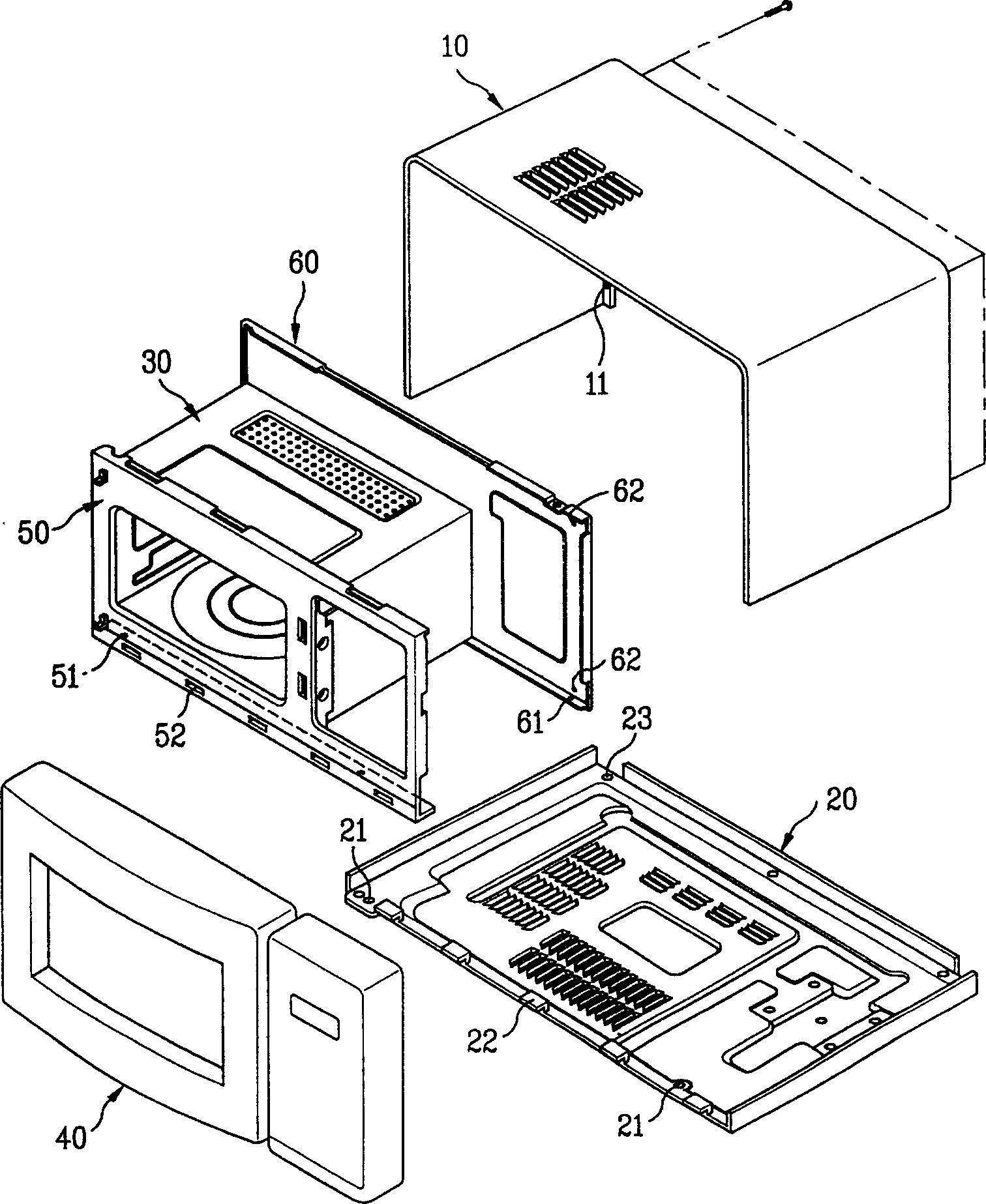

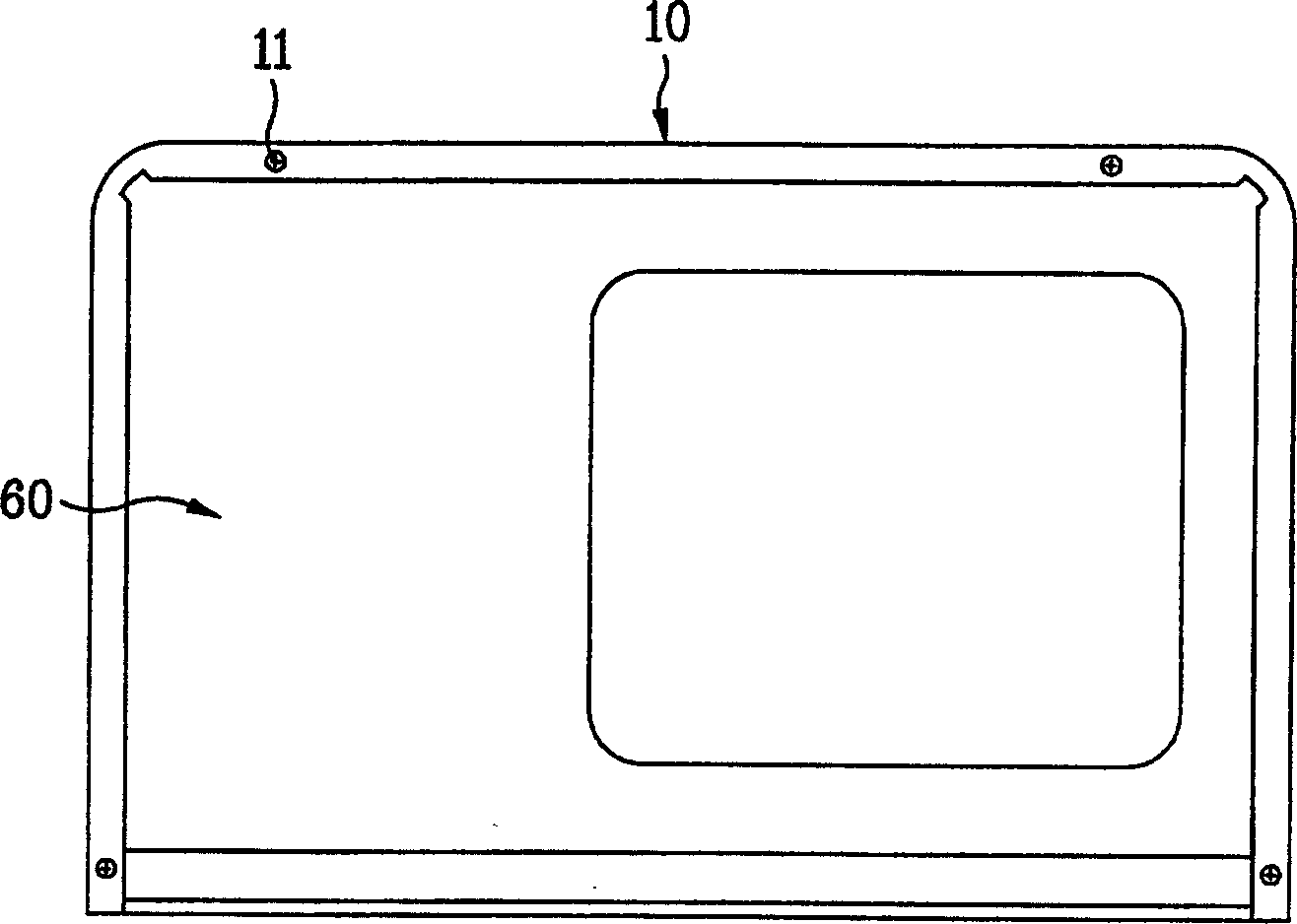

[0038] Refer below Figure 4 to Figure 7 Embodiments of the assembly structure of the microwave oven of the present invention will be described.

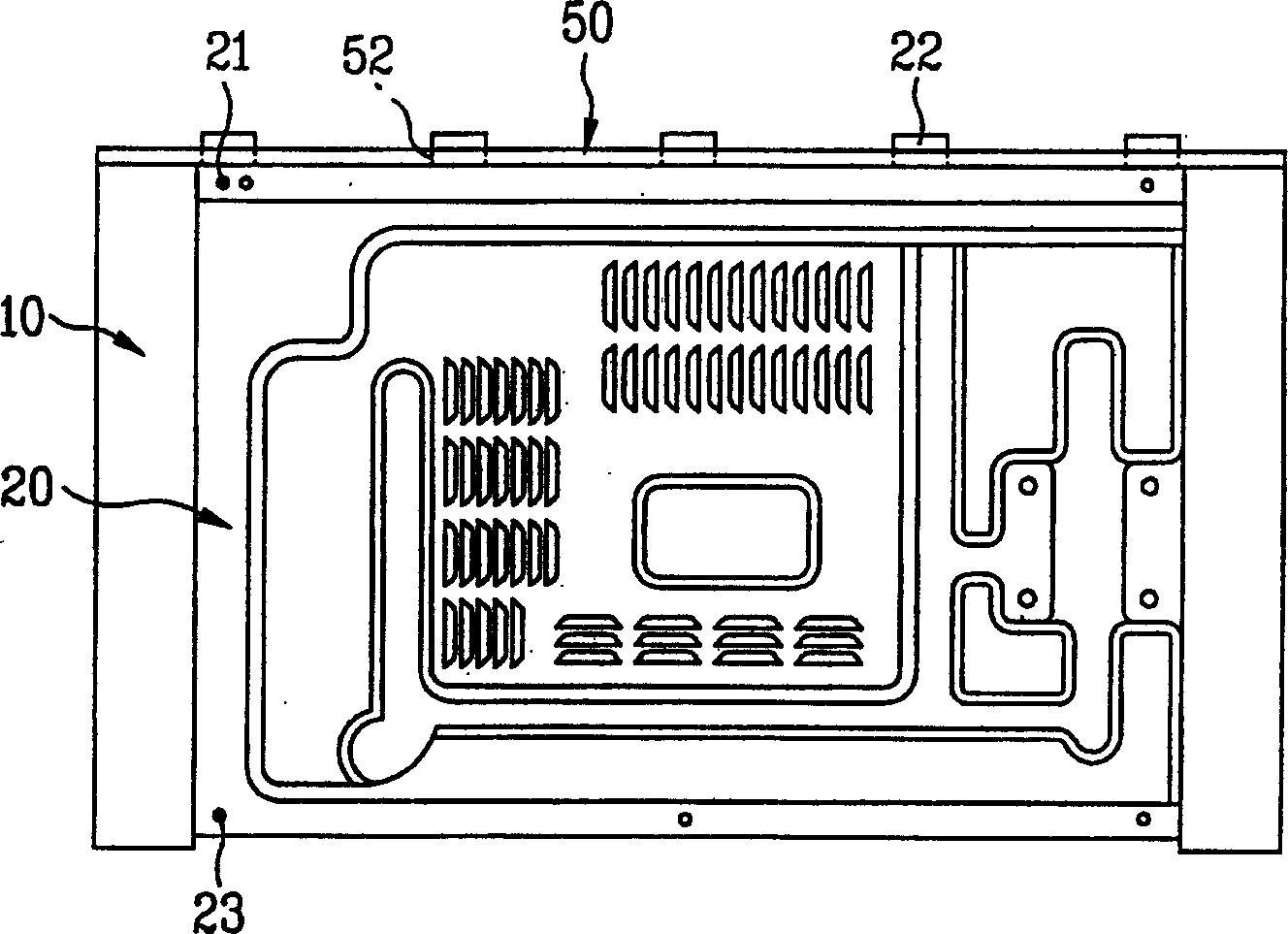

[0039] First, the microwave oven of the present invention is the same as the existing microwave ovens, and also includes the following components, namely: the shell 100 forming the appearance of the machine; the bottom plate 200 forming the bottom surface; the cavity 300 forming the cooking chamber; the door part 400; A front frame 500 integrated with it is formed in front of the cavity 300 ; a rear frame 600 integrated with it is formed in the rear of the cavity 300 .

[0040] A first connection protrusion 210 and a second opening hole 220 are respectively formed on the bottom plate 200 .

[0041] Meanwhile, a plurality of first opening holes 510 are formed on the front frame 500 , and a plurality of second connection protrusions 610 are formed on the rear frame 600 .

[0042] Here, each of the first opening holes 510 is formed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com