Continuous filtration membrane-removal device

The technology of membrane device and box body is applied in the directions of filtration and separation, moving filter element filter, separation method, etc., which can solve the problems of increasing the use cost or maintenance labor cost, increasing the consumption of liquid medicine and operation cost, and easily blocking the filter channel, etc. Achieve the effect of saving manpower, ingenious structural design, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

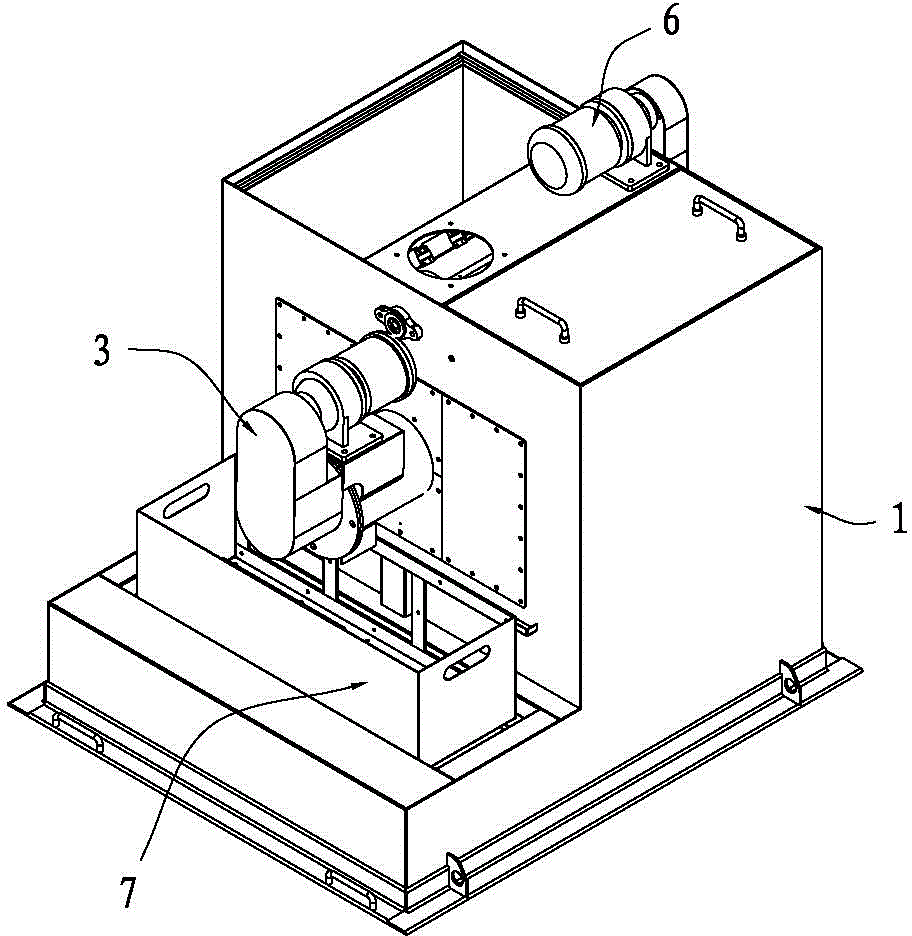

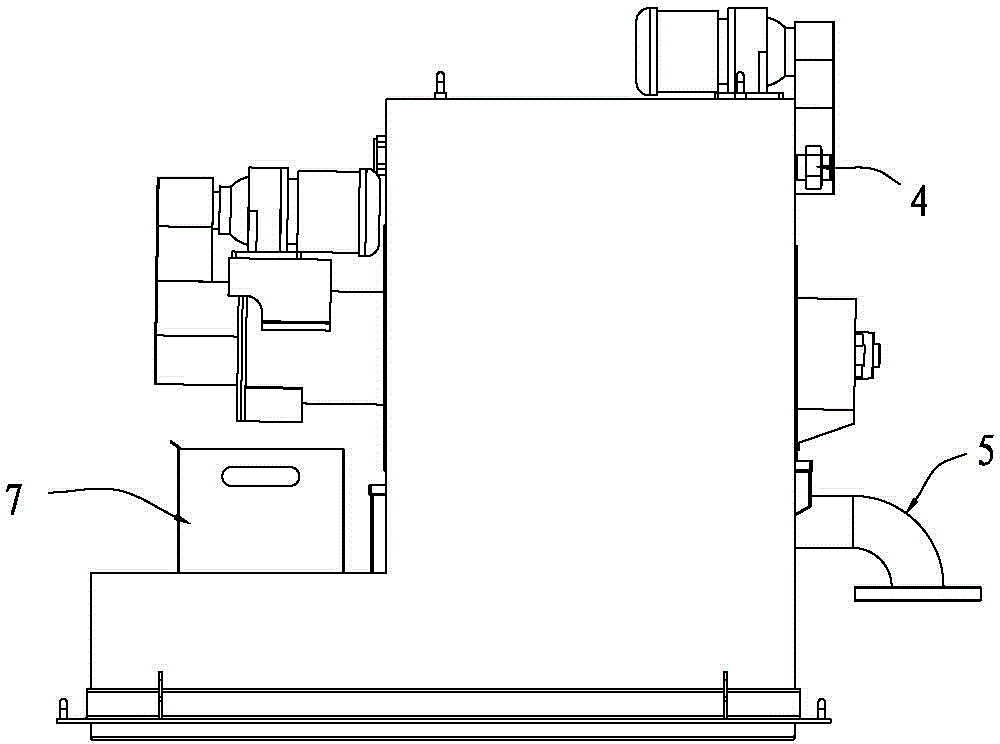

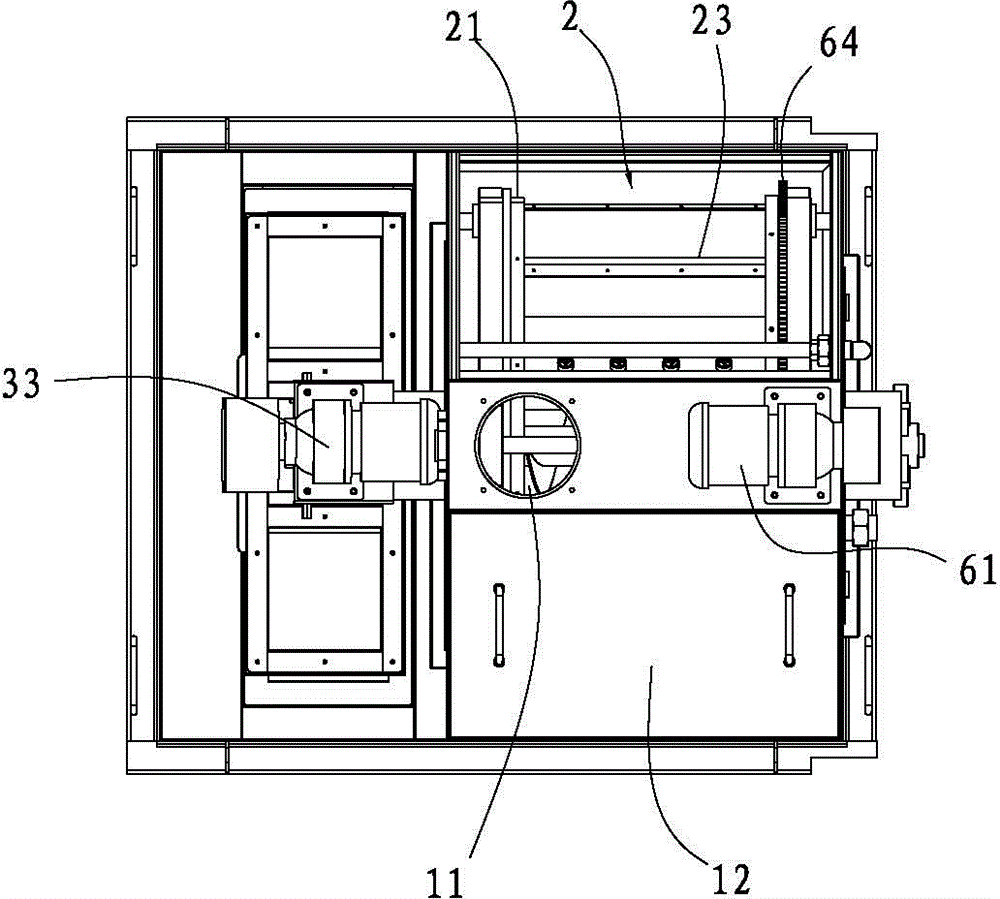

[0022] see Figure 1 to Figure 5 , a continuous filtration film removal device provided in this embodiment, which includes a box body 1, a mesh drum 2, a screw slag discharger 3, a compressed air slag blowing part 4, a liquid inlet pipe 5 and a driving part 6, the mesh The reticulated roller 2 is arranged in the box body 1 in a horizontal state through the support roller 8, that is, the axis of the meshed roller 2 is designed in a horizontal direction, and the driving part 6 is arranged on the said box body 1 and can drive the reticulated roller 2. The mesh drum 2 rotates, one end of the compressed air slag blowing part 4 extends into the box 1, and extends to the upper position of the mesh drum 2, and one end of the spiral slag discharger 3 is set in the box body 1, the other end extends into the box body 1, and protrudes from the box body 1 through the mesh drum 2, and the liquid inlet pipe 5 extends into the box body 1 corresponding to the lower position of the spiral slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com