Composite material boom section for concrete pump truck boom

A technology for concrete pump trucks and composite materials, which is applied in the processing of building materials, construction, building construction, etc., and can solve the problems of poor anti-vibration performance of concrete pump truck booms, low effective bearing capacity of concrete pump trucks, and increasing the number of concrete pump trucks. Chassis load and other issues, to achieve the effect of safe, easy to implement, and strong design adaptability for the manipulator to work at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0030] Such as Figure 5 Shown is a schematic diagram of the boom structure of the concrete pump truck. It can be seen from the figure that the boom frame of the concrete pump truck is composed of multiple boom sections connected end to end in turn. Figure 5 The fourth boom section in is described as an example.

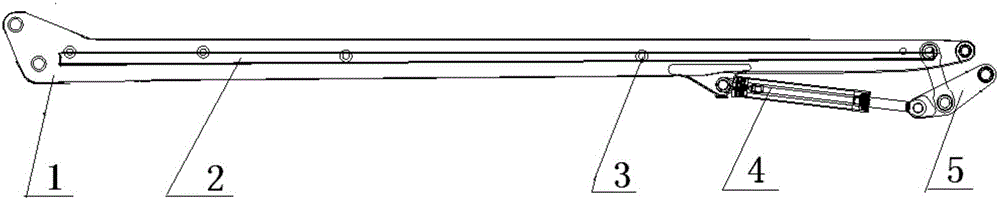

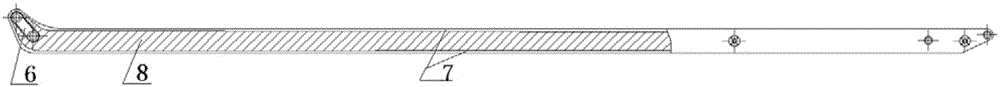

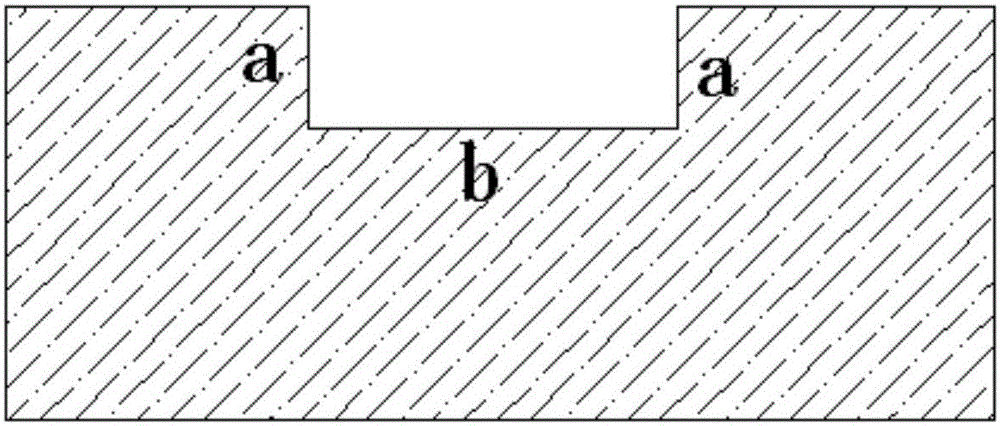

[0031] Such as figure 1 Shown is a structural schematic diagram of the concrete pump truck arm section related to the present invention. The composite boom section consists of a skeleton 1, a concrete delivery pipeline 2, a connecting bolt 3, a hydraulic mechanism 4 and a connecting pin 5; the skeleton 1 includes a large end joint at one end, a main body at the middle and a Small end connector;

[0032] The concrete delivery pipeline 2 is fixed on the side of the main body of the skeleton 1 through the connecting bolt 3; one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com