Self-closed valve for gas transmission pipeline

A transmission pipeline, self-closing technology, applied in the field of self-closing valves, can solve the problems of high production cost, inconvenient transportation and access of dangerous gases, hidden safety hazards, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

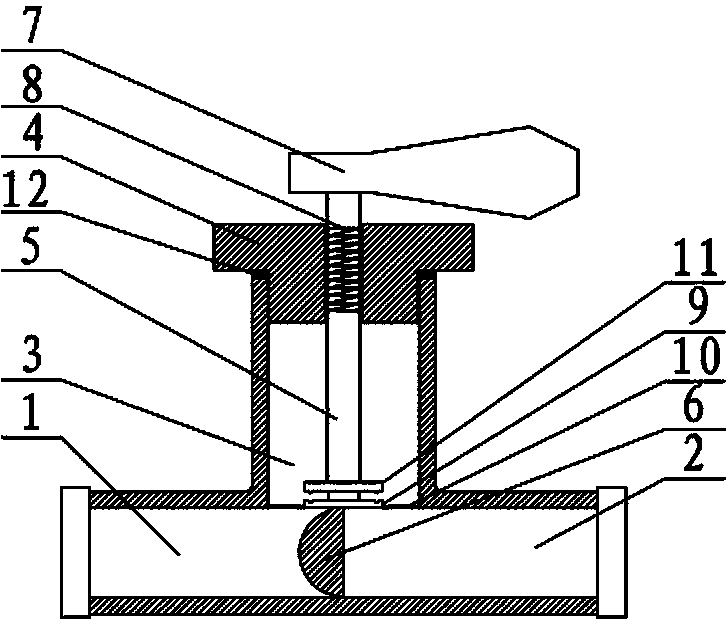

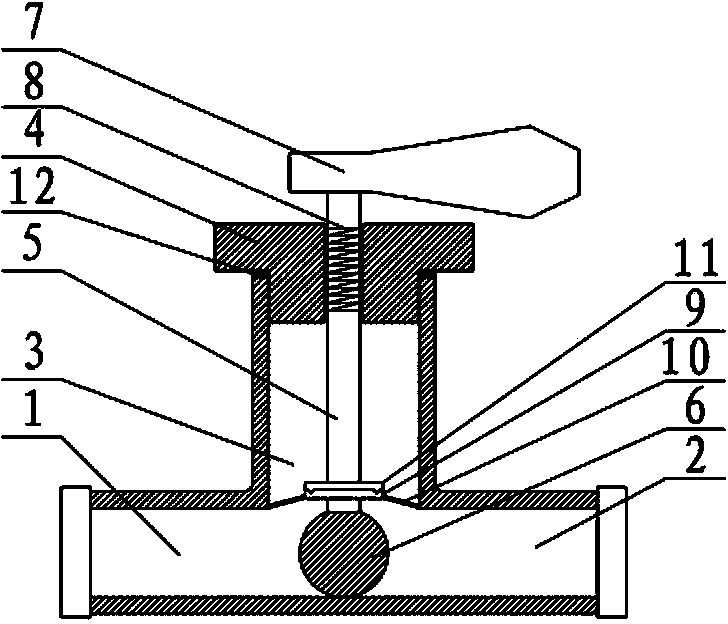

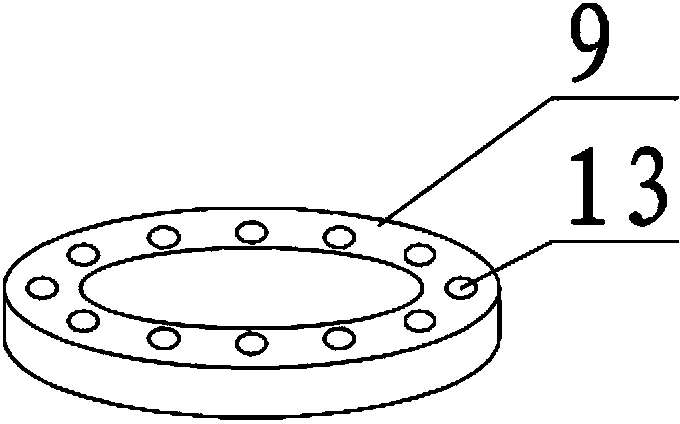

[0018] like Figure 1-4 As shown, the self-closing valve used in the gas delivery pipeline according to the present invention includes a valve body with a T-shaped structure composed of an inlet passage 1, an outlet passage 2 and a control chamber 3. On the upper part of the control chamber 3 A valve cover 4 is provided for sealing, and a sealing ring 12 is arranged on the joint surface of the valve cover 4 and the valve body; The valve core 6 of the hemispherical structure in 2 is fixedly connected; the upper end of the valve stem 5 placed outside the valve cover 4 is provided with a control handle 7; The two ends are respectively connected with the valve stem 5 and the valve cover 4; a positioning plate 9 is slid on the valve stem 5 close to the valve core 6, and the outer peripheral surface of the positioning plate 9 is sealed with the inner wall of the control chamber 3 through a stainless steel elastic ring film 10 Connection; the valve stem 5 above the positioning plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com