Maintenance process for online fast leakage detection for air pre-heater

An air preheater, leak detection technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of overhauling the air preheater of coal-fired boilers, which is not effective. Solve, spend major maintenance time and maintenance costs, restrict the normal operation of coal-fired boilers, etc., to achieve the effect of reducing maintenance personnel, reducing maintenance time, and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

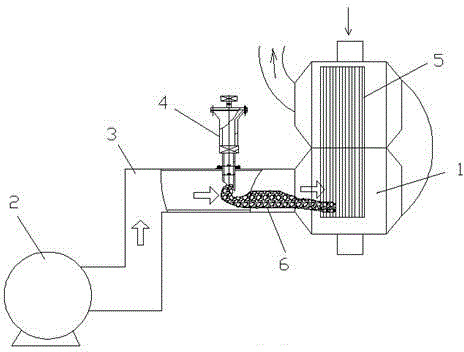

[0021] The maintenance method adopted in the present invention is: install the feeding device 4 on the air supply duct 3 of the air preheater 1, the white lime 6 enters the inner circulation of the air preheater 1 from the feeding device 4, and part of the white lime 6 enters with the high-temperature air supply In the combustion chamber of the boiler, part of the white lime 6 enters the damaged heat exchanger tube 5 in the air preheater 1, and white lime traces appear at both ends of the heat exchanger tube 5, and the heat exchange with white lime traces at both ends The device tube 5 is exactly the damaged heat exchanger tube 5.

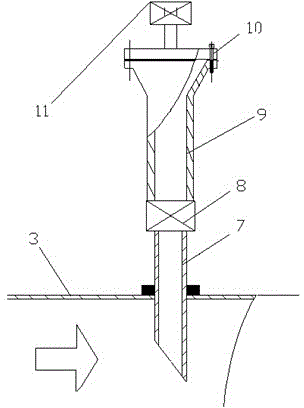

[0022] As shown in the figure, the upper part of the air supply duct 3 of the air preheater 1 is close to 1-1.5 meters of the air preheater 1 to open a hole to install the feeding steel pipe 7, and the length of the feeding steel pipe 7 inside the air supply duct 3 reaches the air supply duct 2 / 3 of the height, the length of the feeding steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com