A Design Method for Fatigue Life of High-rise Towers for Wind and Vibration Resistance

A design method and fatigue life technology, applied in the direction of instruments, calculations, special data processing applications, etc., can solve problems such as leakage, cracking of towers, and reduction of bearing capacity of towering towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

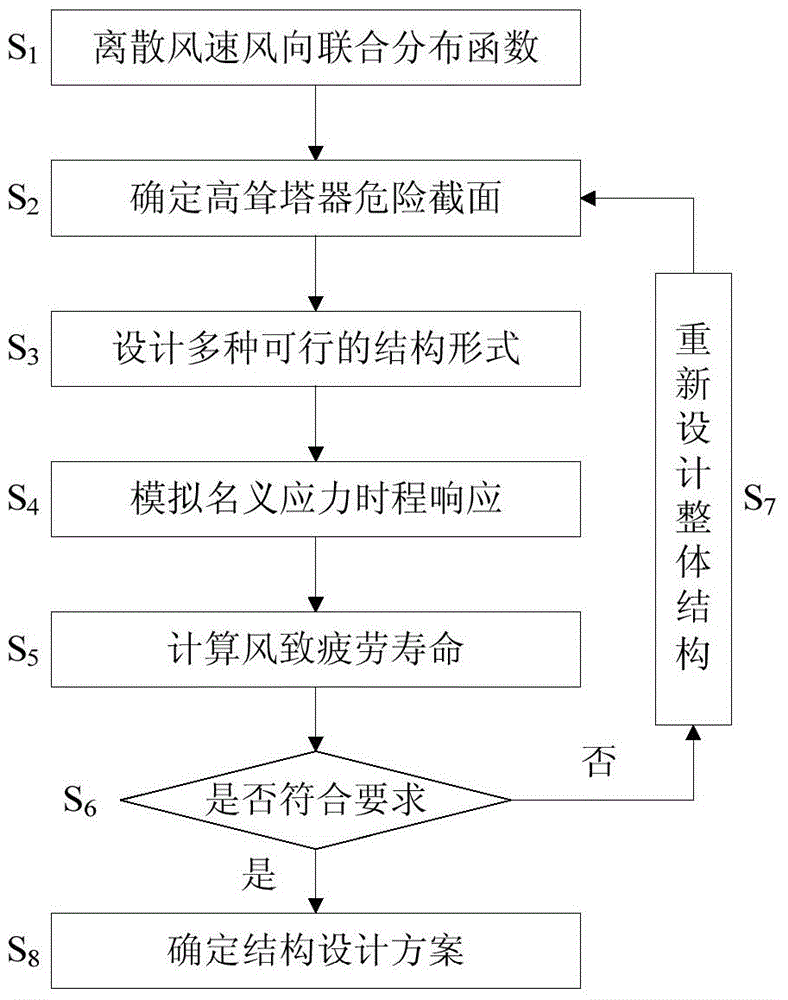

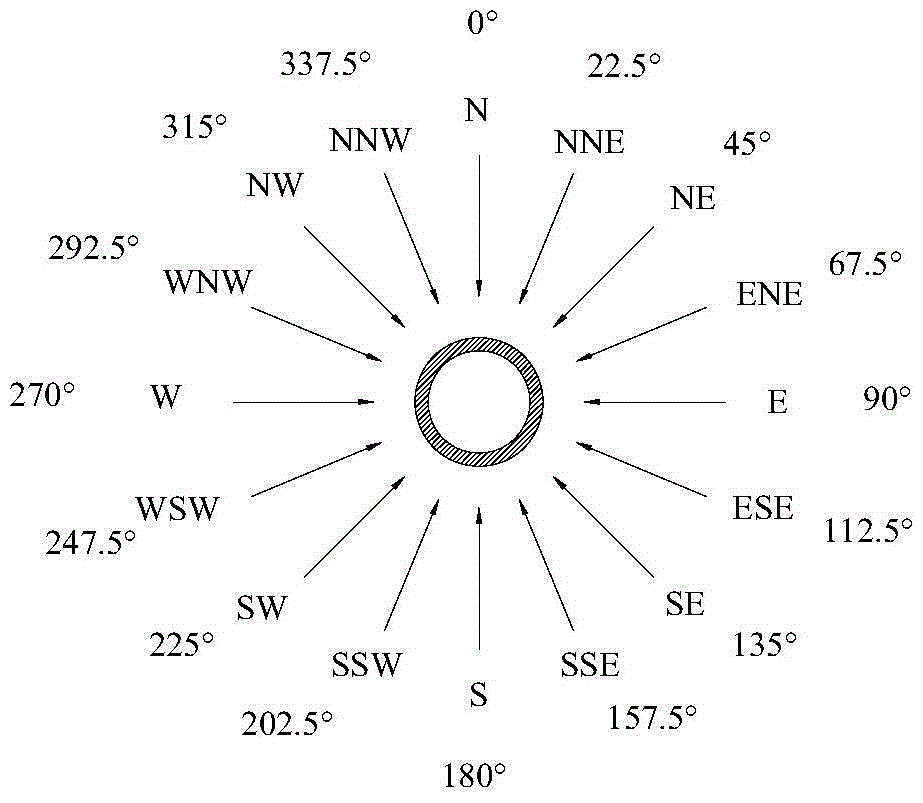

Method used

Image

Examples

Embodiment Construction

[0165] The specific calculation part in this embodiment is not given, please refer to the calculation rules in the prior art for actual calculation.

[0166] The determination of the fatigue curve, welding form and welding defect assessment grade in step S5 of the present invention can refer to the British standard BSI5500-2009 "Specification for Unfired fusion welded pressure vessels" and BS7910-2005 "Guidance on methods for assessing the acceptability of flaws metallic structures”; the specific calculation process in the technical scheme needs to be realized by MATLAB software programming, and the part involving finite element method solution needs to be realized by ANSYS finite element software.

[0167] The method will be further described below in conjunction with the accompanying drawings and embodiments.

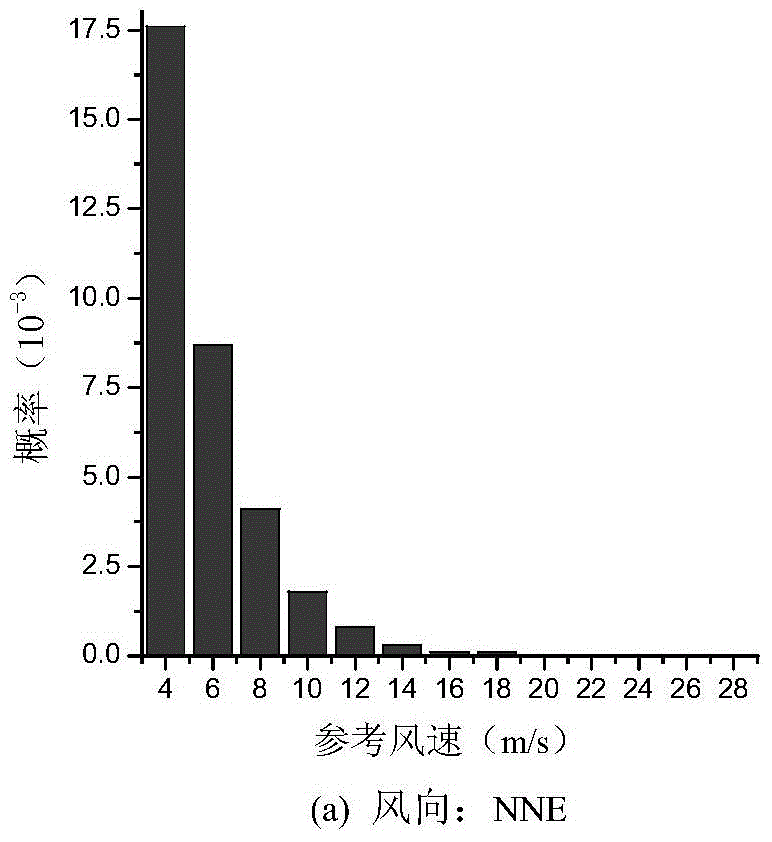

[0168] Fatigue life design for wind resistance and anti-vibration is carried out on a high-rise tower in the coast. The body wall thickness is 14mm, and the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com