truck tire

A technology of tires and carcasses, applied in tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

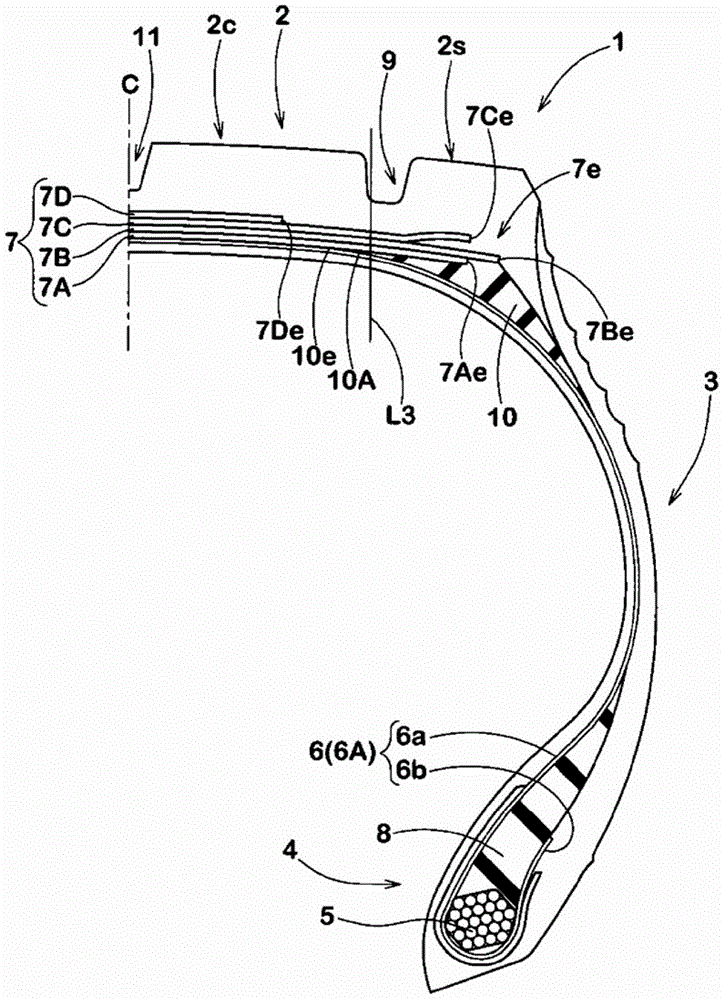

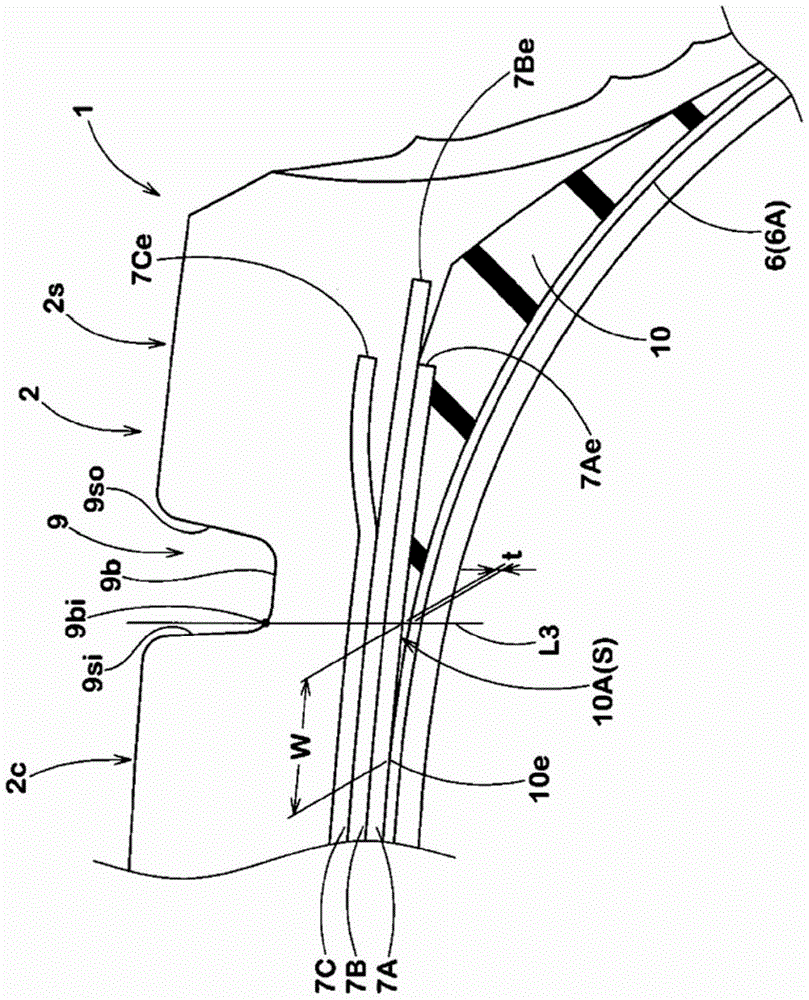

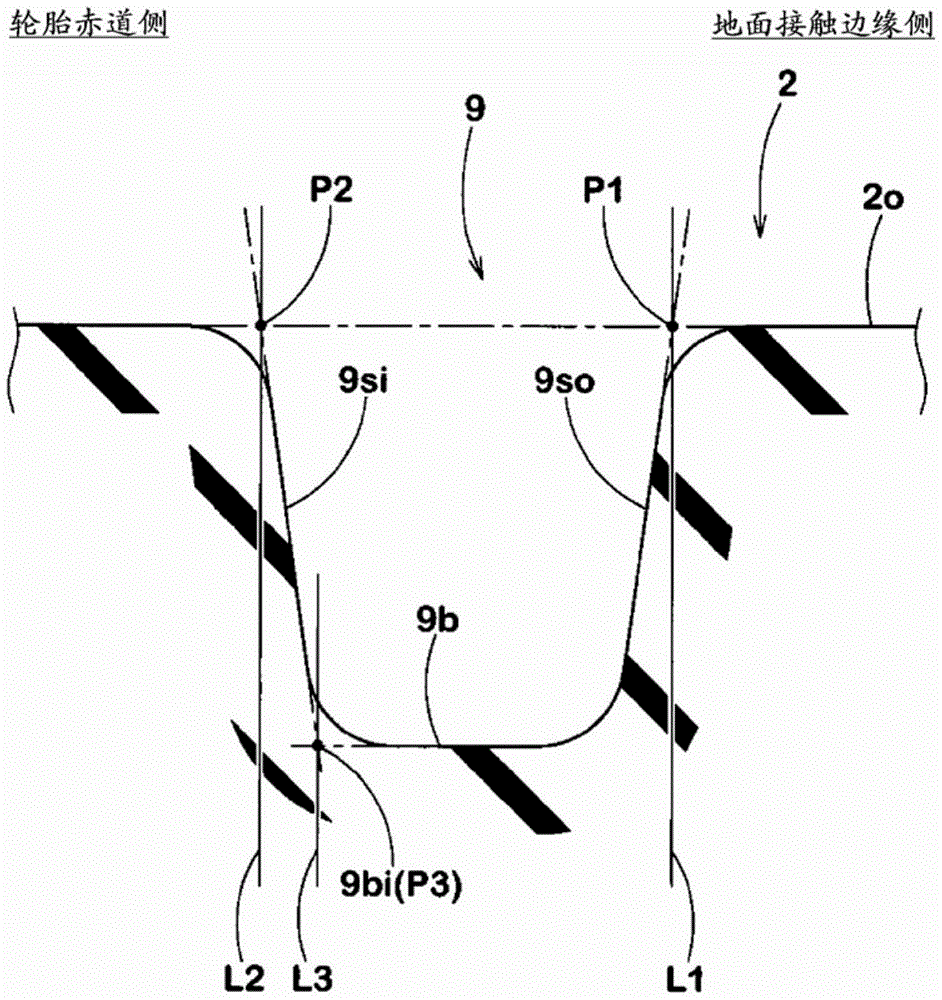

[0023] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 is a cross section of the truck tire 1 according to the present embodiment in a tire meridian section including the tire rotation axis in a standard state. figure 2 Yes figure 1 Enlarged view of tread portion 2 of . image 3 Yes figure 1 A partial enlarged view of the shoulder main groove of .

[0024] "Standard state" means a state where the tire is mounted on a standard rim (not shown) and inflated to a standard pressure but not loaded. Each dimension of a tire is measured in "standard condition" unless otherwise indicated.

[0025] Here, "standard rim" means a rim determined for each tire according to a standard including the standard on which the tire is based, and the standard rim is a standard rim in terms of JATMA, a "Design Rim" in terms of TRA )" and "Measuring Rim (Measuring Rim)" in terms of ETRTO. In addition, "standard internal pressure" me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com