Cyclone separator

A cyclone separator and air inlet technology, which is applied to cyclone devices, devices whose axial directions of cyclones can be reversed, etc., can solve problems such as economic loss, wear of the lower cone of the cyclone separator, and poor separation effect. , to achieve the effect of prolonging the service life, novel design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

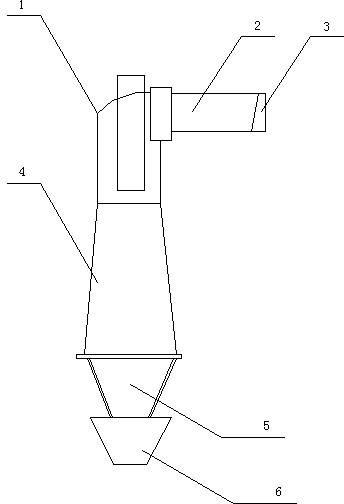

[0010] refer to Figure 1-2 , this specific embodiment adopts the following technical scheme: it includes an upper cylinder 1, an air inlet 2, an air volume adjustment plate 3, a lower cylinder 4, a discharge cone 5 and an ash hopper 6, and the upper cylinder 1 is above one side. The air inlet 2 is provided, the front end of the air inlet 2 is provided with an air volume adjusting plate 3, the lower part of the upper cylinder 1 is connected with the lower cylinder 4, and the lower part of the lower cylinder 4 is provided with a discharge cone 5, and the discharge cone 5 There is an ash hopper 6 below it.

[0011] The lower cylinder body 4 is trumpet-shaped, which improves the separation efficiency of the cyclone separator.

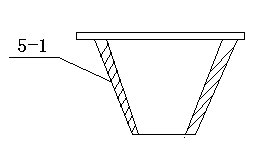

[0012] The inner wall of the discharge cone 5 is provided with an anti-wear ceramic layer 5-1, which has a good anti-wear effect and improves the service time of the cyclone separator.

[0013] This specific embodiment has the following beneficial effect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap