Graphene oxide-semiconductor composite membrane of which oil-water separation performances can be enhanced under illumination

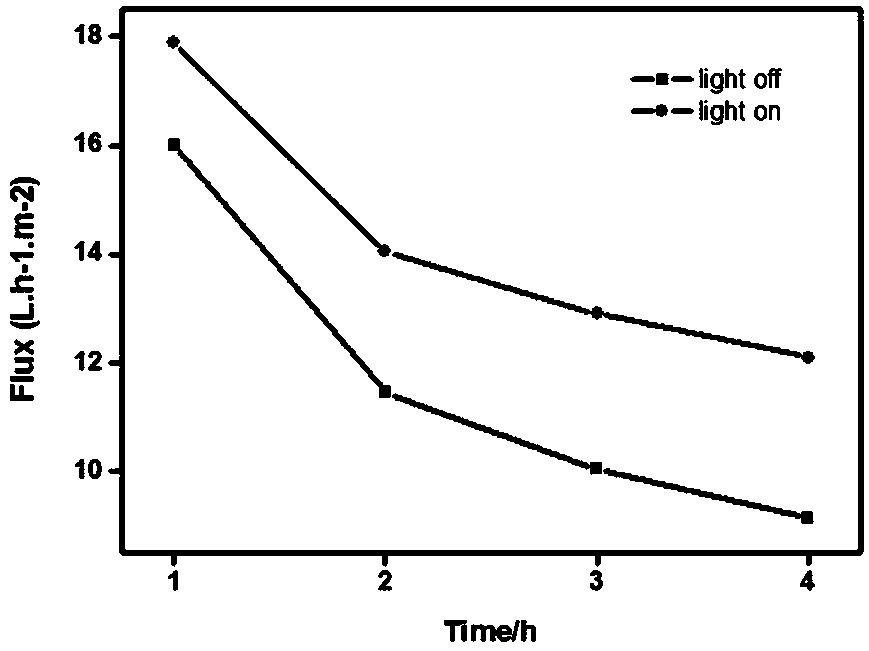

A technology of oil-water separation and graphene, applied in the direction of light water/sewage treatment, liquid separation, separation methods, etc., can solve the problems of narrow permeability of two-dimensional nano-channels, achieve high practical value and application prospects, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

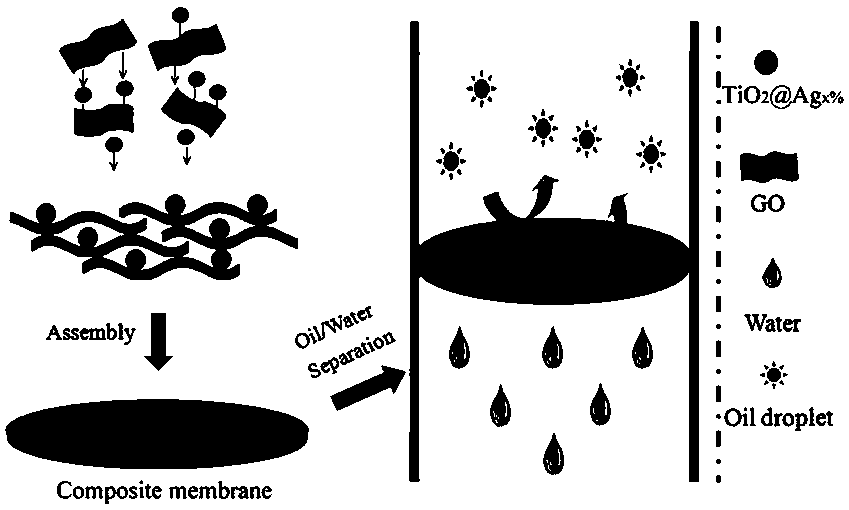

[0023] The preparation steps of the present invention are as follows (as figure 1 shown):

[0024] The first step: disperse the semiconductor nanoparticles and graphene oxide into the aqueous solution according to a certain ratio, and mix the two by stirring, ultrasonic and other methods to form a composite sheet material;

[0025] The second step: put a filter membrane in the filter, and then add the suspension of the graphene oxide-semiconductor particle composite sheet obtained in the first step to the filter; Suction filtration of the suspension to form a graphene oxide-semiconductor particle composite film;

[0026] The third step: On the basis of the membrane obtained in the second step, add oil-water emulsion, and vacuum filter under negative pressure to separate oil and water.

[0027] The fourth step: On the basis of the third step, real-time light is applied to filter and separate oil and water.

Embodiment 1

[0029] Preparation of graphene-semiconductor particle composite separation membrane with light-enhanced oil-water separation performance

[0030] The first step: combining graphene oxide with TiO 2 @Ag 0.1% Mix according to the mass ratio of 1:5, and form a mixed suspension after stirring;

[0031] Step 2: Put a filter membrane in the filter, add a composite suspension containing 2.0 g of graphene oxide per square meter of filter area to the filter; filter the suspension under a negative pressure of 10 Pa to form an oxide Graphene-semiconductor particle film.

Embodiment 2

[0033] Preparation of graphene-semiconductor particle composite separation membrane with light-enhanced oil-water separation performance

[0034] The first step: combining graphene oxide with TiO 2 @Ag 0.1% Mix according to the mass ratio of 1:10, and form a mixed suspension after stirring;

[0035] Step 2: Put a filter membrane in the filter, add a composite suspension containing 0.1 g of graphene oxide to the filter per square meter of filter area; filter the suspension under a negative pressure of 5 Pa to form an oxide Graphene-semiconductor particle film.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap