Integrated slurry treatment system

A treatment system and integrated technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of restricted pipeline transportation, troublesome pipeline installation, difficult to separate, etc., and achieve simplification Difficulty, efficiency improvement, waste reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

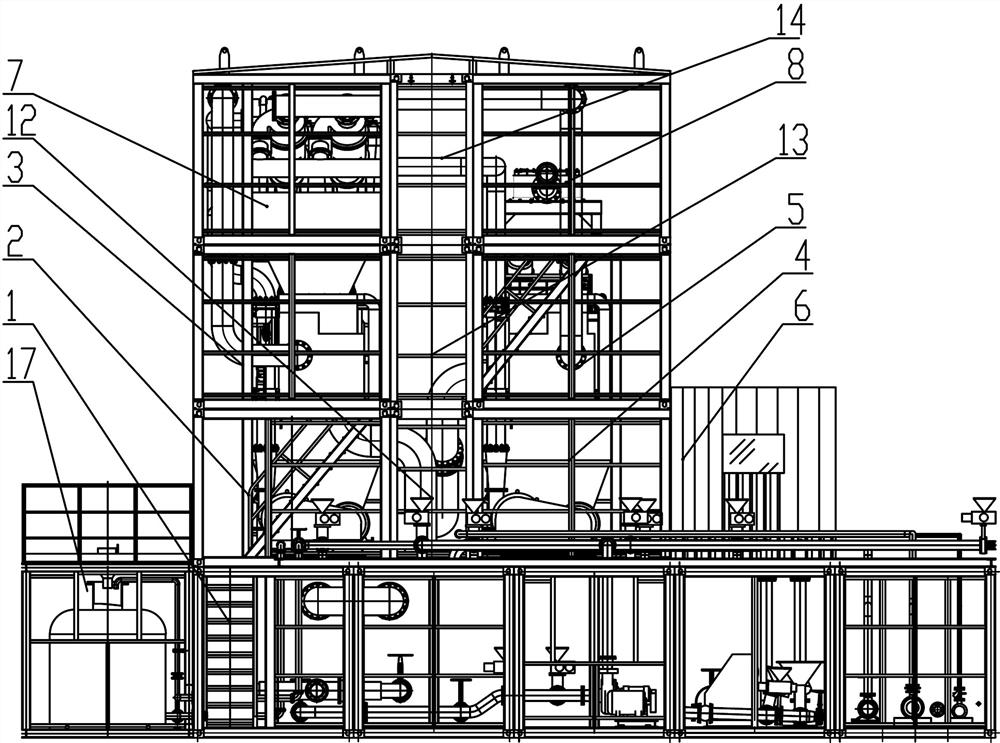

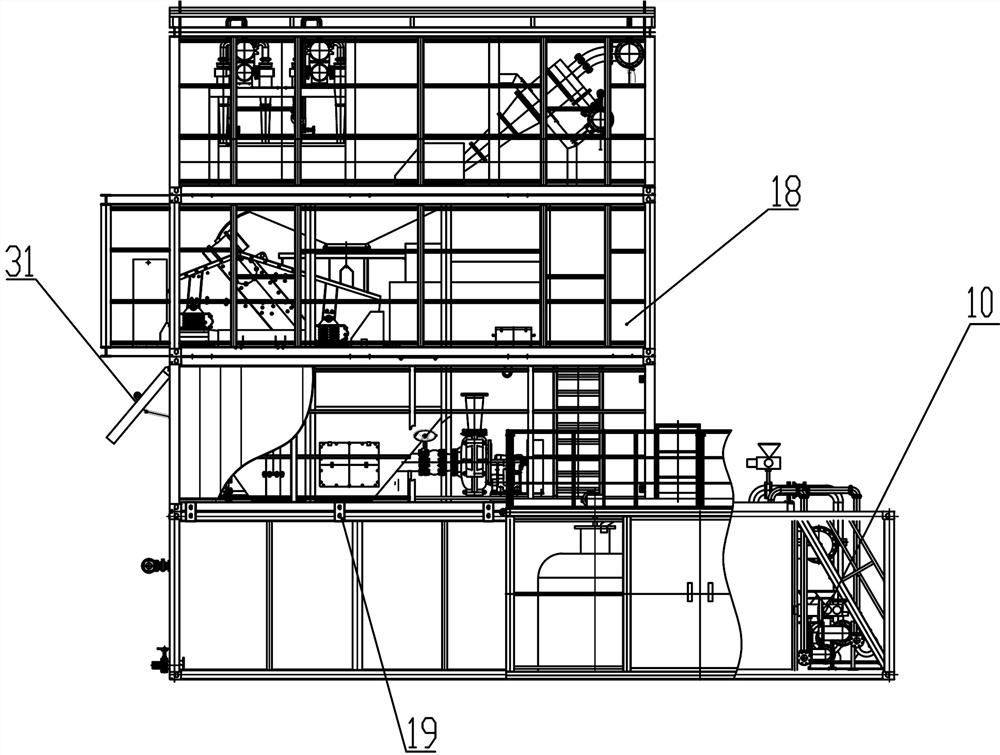

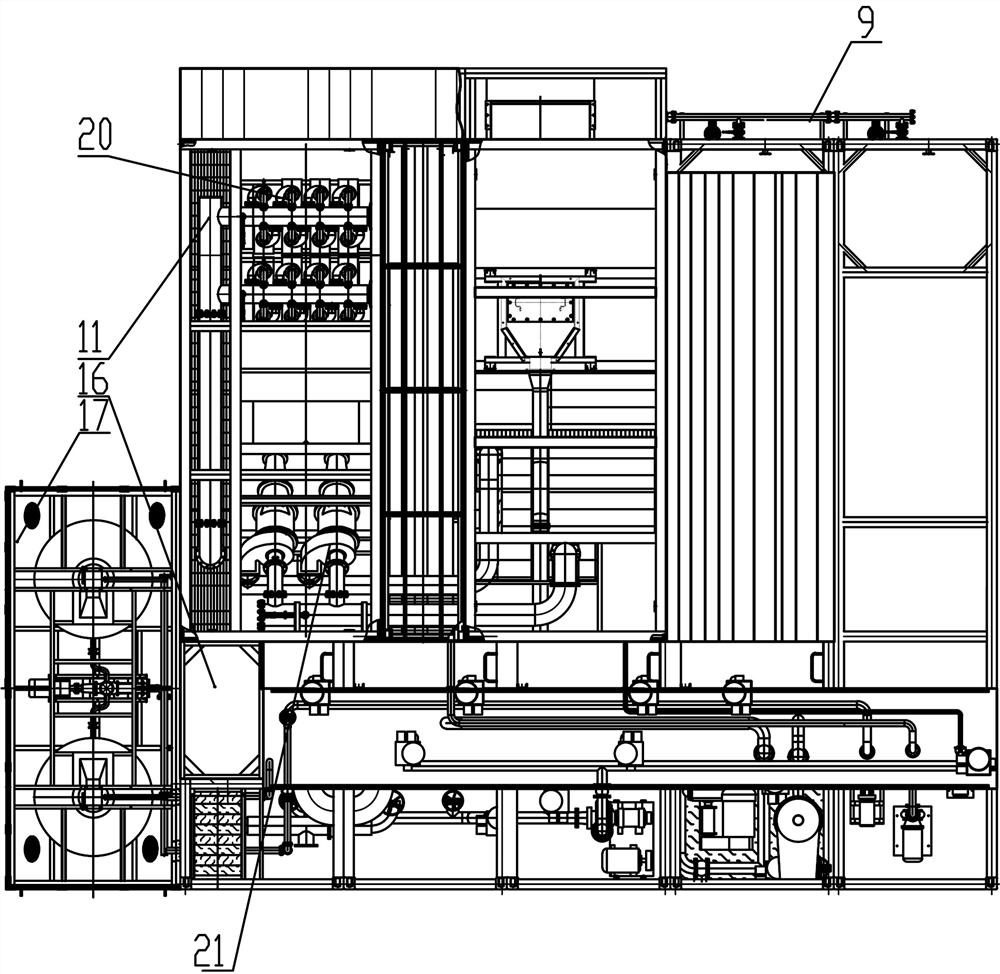

[0035] Such as Figure 1~3 Among them, an integrated mud treatment system, which includes a mud box assembly 1, and a secondary slurry storage tank frame assembly 2 and a primary slurry storage tank frame assembly 4 are arranged above the mud box assembly 1;

[0036] A dewatering screen frame assembly 3 is provided on the frame assembly 2 of the secondary slurry storage tank, and a pre-screen frame assembly 5 is provided on the frame assembly 4 of the primary slurry storage tank;

[0037] A cyclone frame assembly 7 is arranged on the frame assembly 2 of the secondary slurry storage tank, and a pre-screening slurry inlet frame assembly 8 is arranged on the pre-screening frame assembly 5 . With this structure, the pipeline structure can be simplified, thereby reducing the number of frame assemblies.

[0038] The preferred solution is as figure 1 , 3 Among them, the secondary slurry storage tank frame assembly 2 and the primary slurry storage tank frame assembly 4 are located ...

Embodiment 2

[0057] The preferred solution is as figure 1 , 3 , 5, also be provided with circulation pulping system 17, circulation pulping system 17 is provided with new pulp box 25, clean water box 26, waste pulp box 27 and pulp mixing box 28, feed hopper 30 is mixed with new pulp by shearing pump The box 25 is connected, and the incoming new mud is evenly mixed under the action of the shear pump. The overflow port of the secondary slurry storage tank and the primary slurry storage tank is connected with the slurry mixing box 28, and a valve is provided on the connected pipeline. For switching the mud from different slurry storage tanks according to the liquid levels of the slurry distribution box 28, the secondary slurry storage tank and the primary slurry storage tank, see image 3 . The new slurry box 25 is connected with the slurry matching box 28, and is used to mix new slurry in the recovered slurry, so that the clear water box 26 is connected with the new slurry box 25, the wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com