Tin dross separating and reclaiming device

A technology for separation and recovery of tin slag, applied in the direction of improving process efficiency, can solve the problems of troublesome operation, production waste, large volume, etc., and achieve the effect of simple structure, high efficiency and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

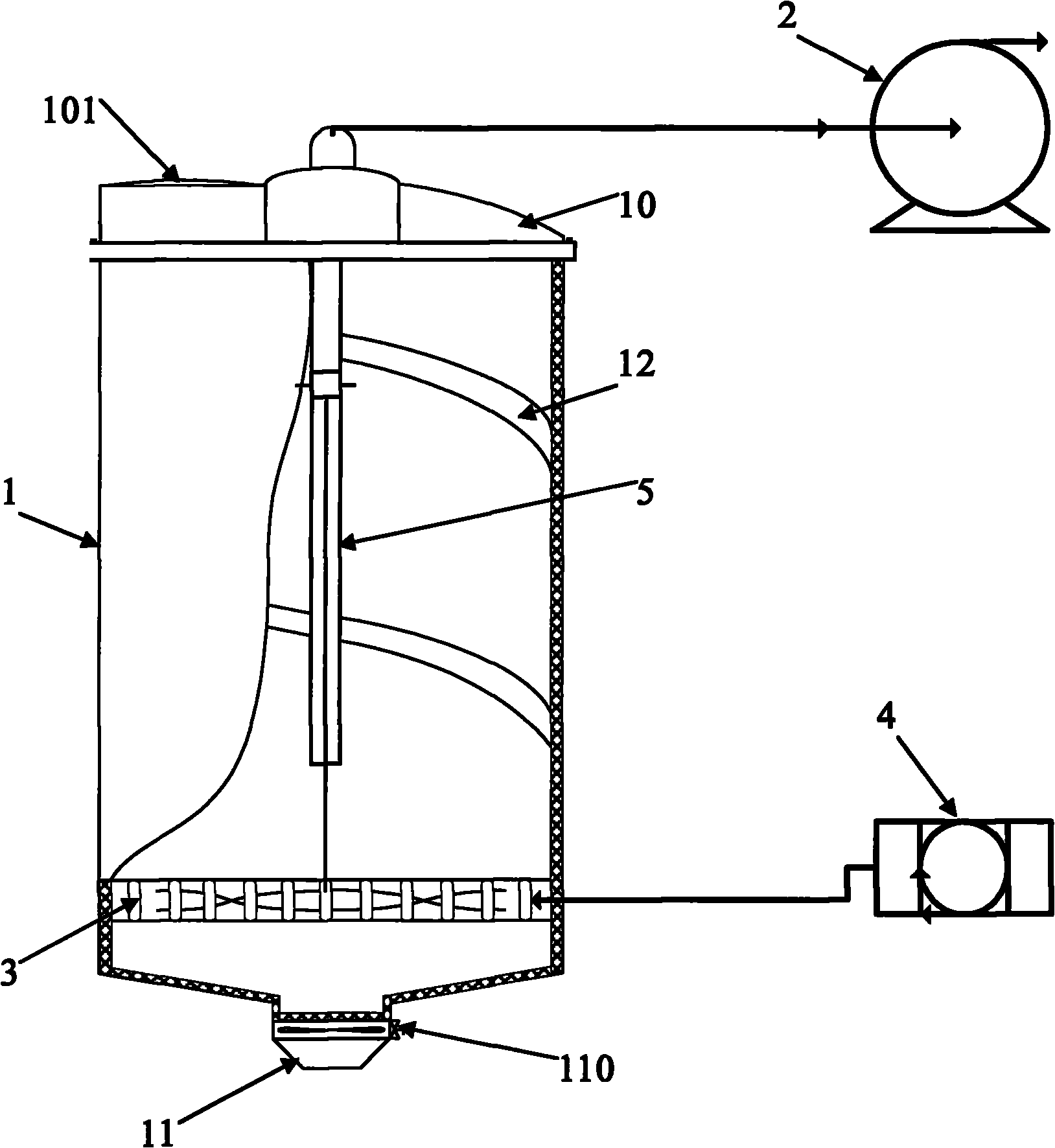

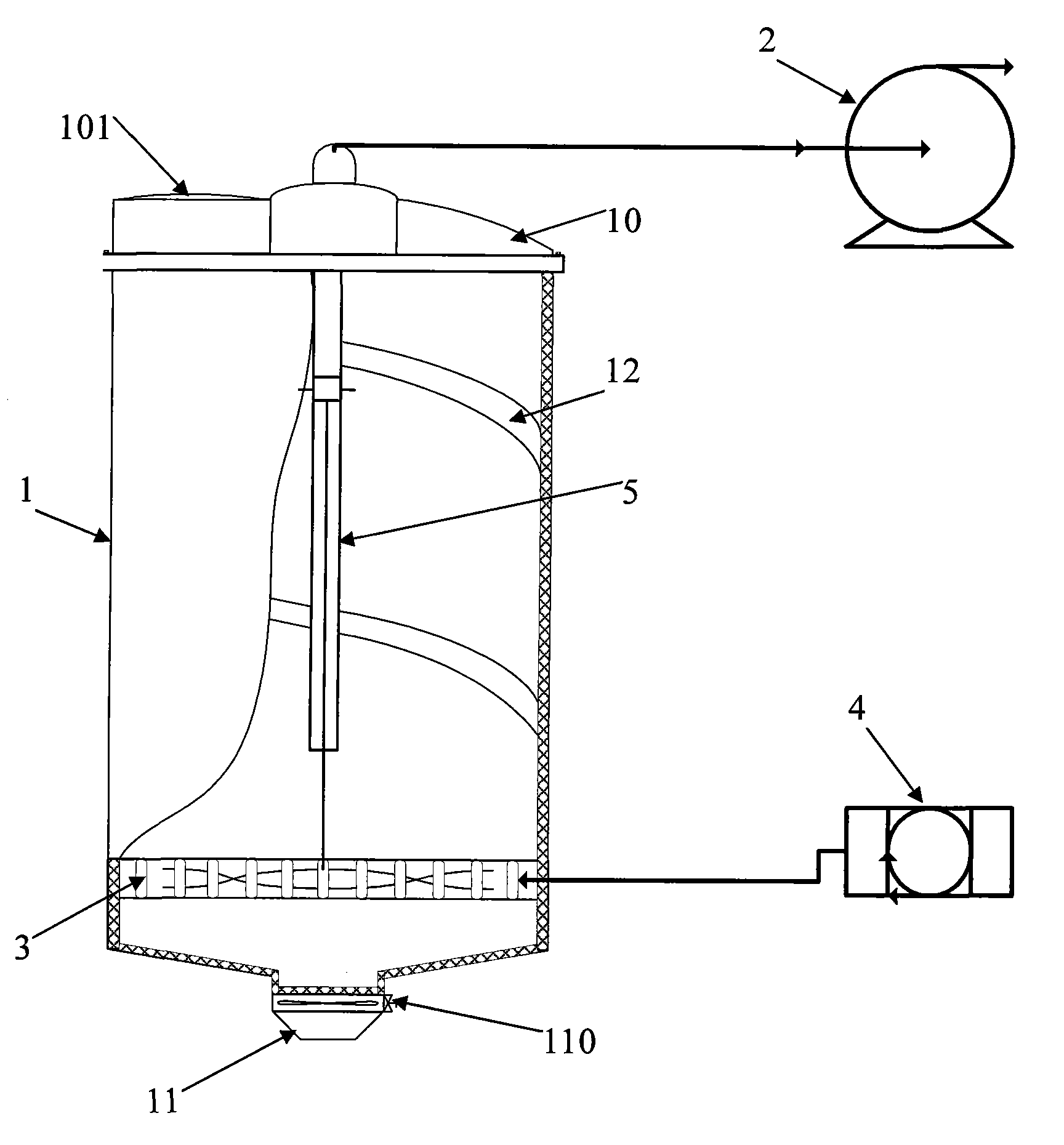

[0008] see figure 1 As shown, a tin slag separation and recovery device of the present invention includes a tin slag container 1 for containing tin slag, a vacuum pump system 2 installed on the top of the tin slag container 1, and an electric heating device installed at the bottom of the tin slag container 1 Control System. Wherein, the tin slag container 1 is a steel metal can-shaped container, and the top of the main body of the tin slag container 1 is provided with a top cover 10, and the top cover 10 is connected with the main body of the tin slag container 1 by screws. The top cover 10 is partially provided with a feed port 101 with a locking cover, and the tin slag to be separated is poured into the tin slag container 1 from the feed port 101 . The lower part of the main body of the tin slag container 1 is provided with a discharge port 11 with a valve 110 , and the metal solder and tin ash after separation of the tin slag are discharged from the discharge port 11 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com