Laser separation machining method and device for optical crystal

An optical crystal and laser technology, used in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of increasing the difficulty of optical crystal processing, changing the optical performance of optical crystals, and losing control of the separation processing direction, so as to improve the separation processing efficiency. , the separation processing mouth is steep, the effect of suppressing negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

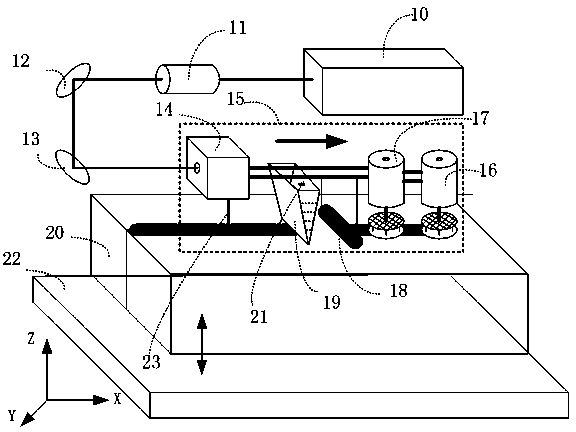

[0047] The present invention adopts an output wavelength of 1070nm, an output peak laser power of 50W, and a pulse energy of 1J as a fiber laser with a low peak power and a high-energy laser beam. The diameter of the focused spot is 50 μm, and the size of the separated and processed DKDP optical crystal sample is the length 60mm, thickness 12mm. Apply DKDP saturated optical crystal solution on the surface of DKDP optical crystal after simple rough grinding, polishing and wiping. The separation processing speed is 0.6m / min, the peak output power of the fiber laser is 50W, the pulse energy is 1J, and the scanning speed is 1m / min. Experimental results: The optical crystal is separated along the laser scanning line direction, without fragmentation, high separation precision, steep separation processing mouth, and smooth separation processing surface.

example 2

[0049] The present invention adopts a YLM-200 type optical brazing laser, the output wavelength is 1064nm, the output continuous laser power is 200W, and the diameter of the focused spot is 80μm respectively. Experimental method: Use KDP saturated optical crystal solution to coat on the surface of KDP optical crystal after simple rough grinding, polishing and wiping. The output power of the separated processed fiber laser is 175W, and the scanning speed is 1.8m / min. Experimental results: The optical crystal is separated along the direction of the laser scanning line, and the separation end face is relatively rough. It needs to be polished to obtain the optical plane required in the application.

example 3

[0051] The present invention adopts the Awave-532-20-25K type green laser, the output wavelength is 532nm, the output maximum single pulse energy is 40μJ, the focus spot diameter is 20μm respectively, and the lithium acid (LiNbO3-LN) optical crystal is separated, and the size is Length 98mm, thickness 10mm. Experimental method: Coat the saturated optical crystal solution of lithium-acid optical crystals on the surface of lithium-acid optical crystals after simple rough grinding, polishing and wiping, and the laser scanning speed is 1.3m / min. Scanning and separation processing along the direction of the coating liquid track, after separation, the processed end surface is relatively smooth, and there are no cracks in other directions inside the optical crystal. Simple mechanical smoothing and polishing are required to obtain the optical plane required in the application.

[0052] This method can also be used for laser separation and processing of other optical crystals by liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com