Mesoporous carbon @TiO2 core-shell spheres and preparation method thereof

A technology of mesoporous carbon and core-shell spheres is applied in the field of mesoporous carbon@TiO2 core-shell spheres and their preparation, which can solve the problems of low solar photocatalytic efficiency and small specific surface area, and achieve the effect of simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A Mesoporous Carbon@TiO 2 The preparation method of core-shell sphere comprises the following steps:

[0028] 1) Mix ethylene glycol and acetone at a mass ratio of 2:1 to obtain solution A;

[0029] 2) Add mesoporous carbon spheres with a particle size of 306nm into solution A, and ultrasonically disperse them uniformly to obtain suspension B;

[0030] 3) Add tetrabutyl titanate to suspension B, the mass ratio of tetrabutyl titanate to mesoporous carbon spheres is 5:1, and obtain suspension C after ultrasonic dispersion;

[0031] 4) Transfer the suspension C to a magnetically stirred high-pressure reactor with a filling degree of 50% and a magnetic stirring speed of 300r / min, and react at 150°C for 12 hours to obtain the solvothermal product D;

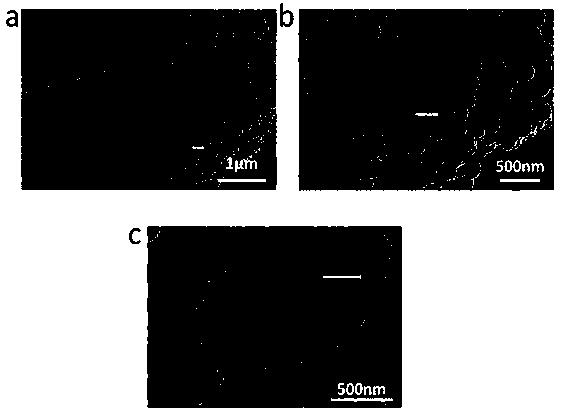

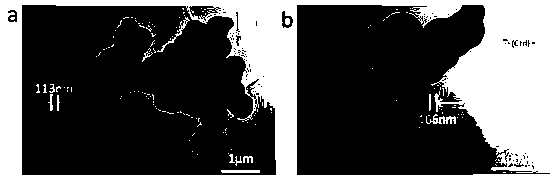

[0032] 5) The solvothermal product D was centrifuged, washed with deionized water and ethanol, dried at 80°C for 12 hours, and ground to obtain mesoporous carbon @TiO 2 Core-shell spheres, mesoporous carbon @TiO 2 The SEM a...

Embodiment 2

[0034] A Mesoporous Carbon@TiO 2 The preparation method of core-shell sphere comprises the following steps:

[0035] 1) Mix ethylene glycol and acetone at a mass ratio of 2:1 to obtain solution A;

[0036] 2) Add mesoporous carbon spheres with a particle size of 306nm into solution A, and ultrasonically disperse them uniformly to obtain suspension B;

[0037] 3) Add tetrabutyl titanate to suspension B, the mass ratio of tetrabutyl titanate to mesoporous carbon spheres is 10:1, and obtain suspension C after uniform ultrasonic dispersion;

[0038] 4) Transfer the suspension C to a magnetically stirred high-pressure reactor with a filling degree of 50% and a magnetic stirring speed of 350r / min, and react at 160°C for 14 hours to obtain the solvothermal product D;

[0039] 5) The solvothermal product D was centrifuged, washed with deionized water and ethanol, dried at 80°C for 12 hours, and ground to obtain mesoporous carbon @TiO 2 Core-shell spheres, mesoporous carbon @TiO 2 ...

Embodiment 3

[0041] A Mesoporous Carbon@TiO 2 The preparation method of core-shell sphere comprises the following steps:

[0042] 1) Mix ethylene glycol and acetone at a mass ratio of 3:1 to obtain solution A;

[0043] 2) Add mesoporous carbon spheres with a particle size of 306nm into solution A, and ultrasonically disperse them uniformly to obtain suspension B;

[0044] 3) Add tetrabutyl titanate to suspension B, the mass ratio of tetrabutyl titanate to mesoporous carbon spheres is 5:1, and obtain suspension C after ultrasonic dispersion;

[0045] 4) Transfer the suspension C to a magnetically stirred high-pressure reactor with a filling degree of 80% and a magnetic stirring speed of 400r / min, and react at 180°C for 18 hours to obtain the solvothermal product D;

[0046] 5) The solvothermal product D was centrifuged, washed with deionized water and ethanol, dried at 90°C for 20 hours, and ground to obtain mesoporous carbon @TiO 2 Core-shell spheres, mesoporous carbon @TiO 2 The SEM a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap