A clamp with self-locking function

A fixture and function technology, applied in the field of fixtures with self-locking function, can solve the problems of changing clamping positioning state, complex structure, heavy weight, etc., and achieve reliable clamping, increased feeding space, and convenient loading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

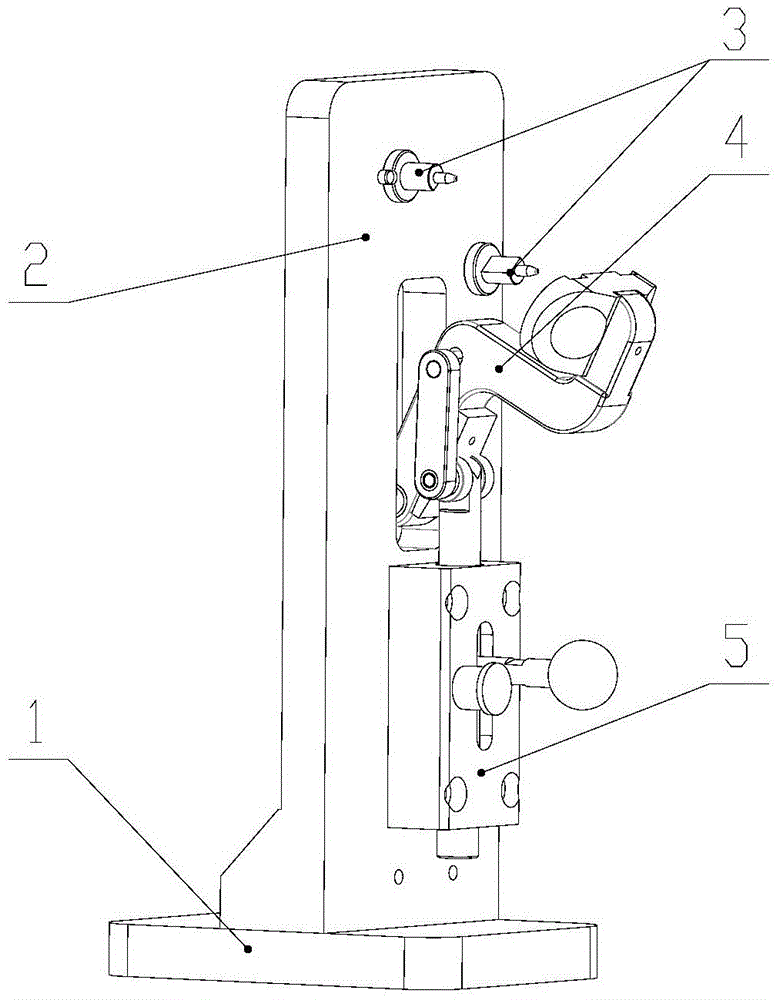

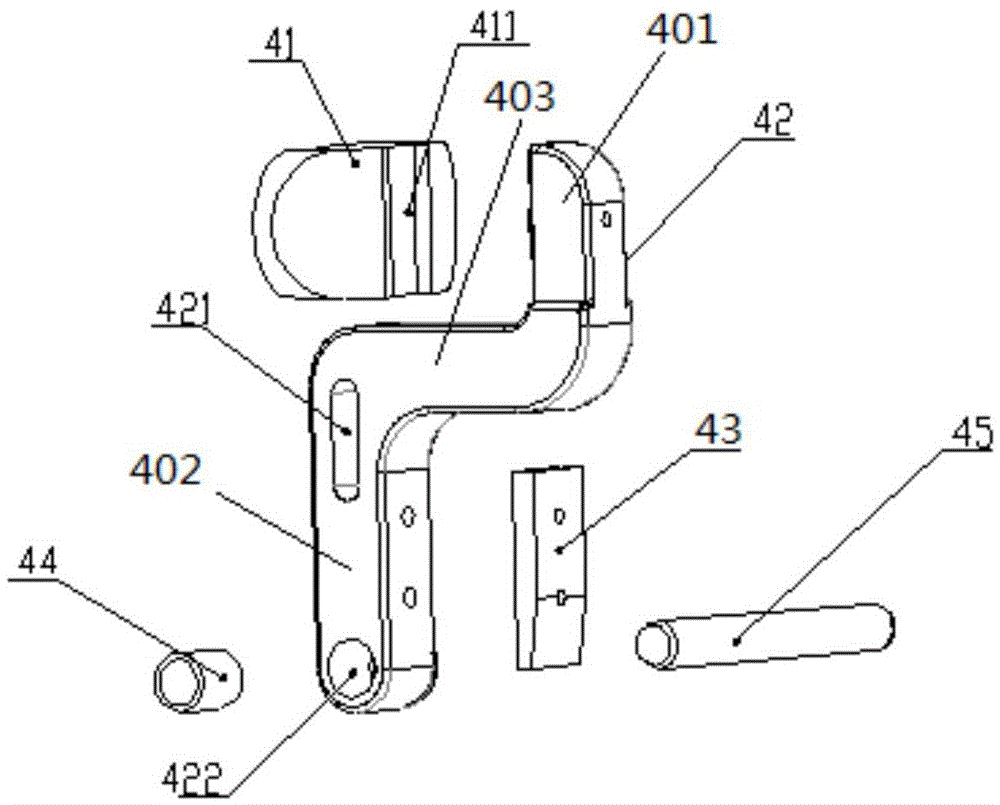

[0038] see Figure 1-4 , The present invention is a fixture with self-locking function, which includes: fixture base 1, fixture vertical plate 2, workpiece positioning pin 3, pressing assembly 4 and guide assembly 5.

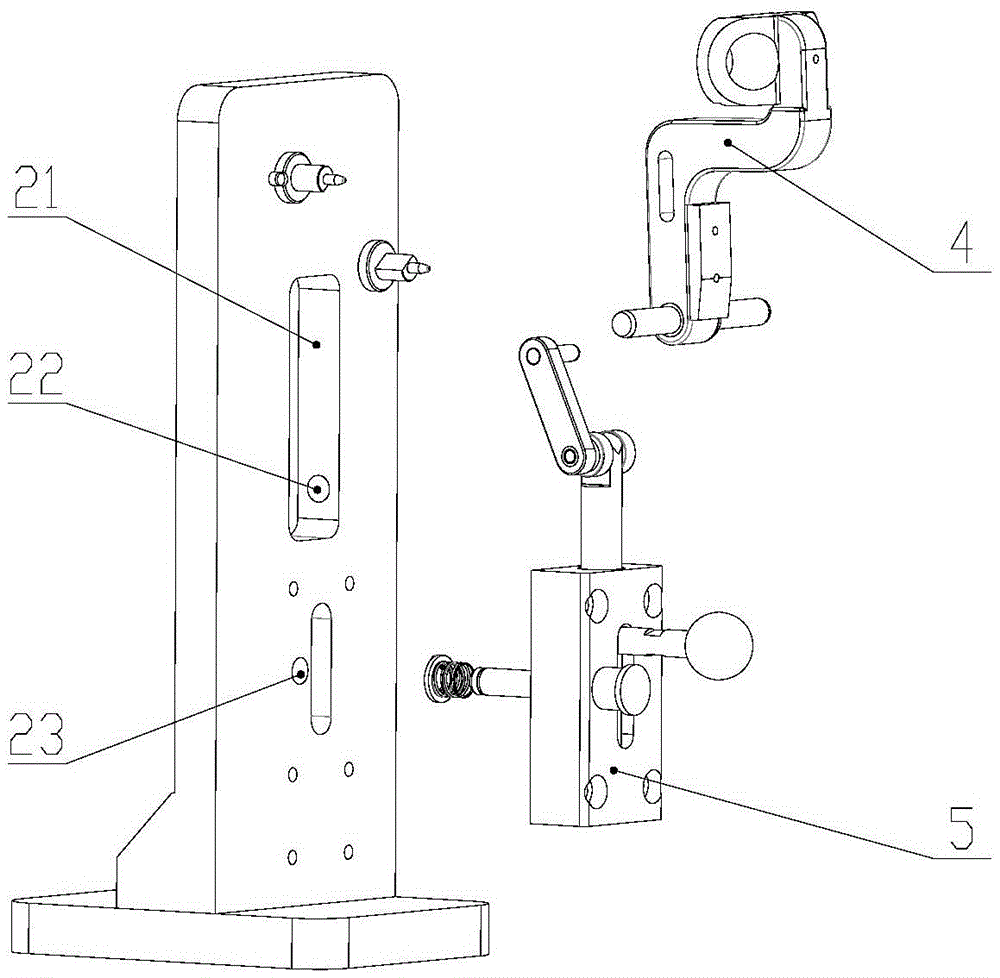

[0039] The clamp vertical plate 2 is vertically fixedly connected to the top surface of the clamp frame 1 by bolts, and the front side of the clamp vertical plate 2 is provided with a vertically extending relief groove 21 and a lock located obliquely below the relief groove 21. Rod passing holes 23 , wherein, rotation pin installation holes 22 are symmetrically opened on the opposite left and right sides of the relief groove 21 .

[0040] The workpiece positioning pins 3 are used to locate the workpiece to be clamped, and the number is at least two. These workpiece positioning pins 3 are arranged on the front side of the fixture ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com